Automatic vehicle exterior light control

a technology of automatic control and vehicle exterior, which is applied in the direction of point-like light sources, lighting and heating apparatus, transportation and packaging, etc., can solve the problems of inability to consider oncoming or leading vehicles in determining the illumination range of headlamps, the increase in the brightness and bluish color of hid lamps is particularly disruptive to oncoming drivers, and the change in illumination that may startle drivers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

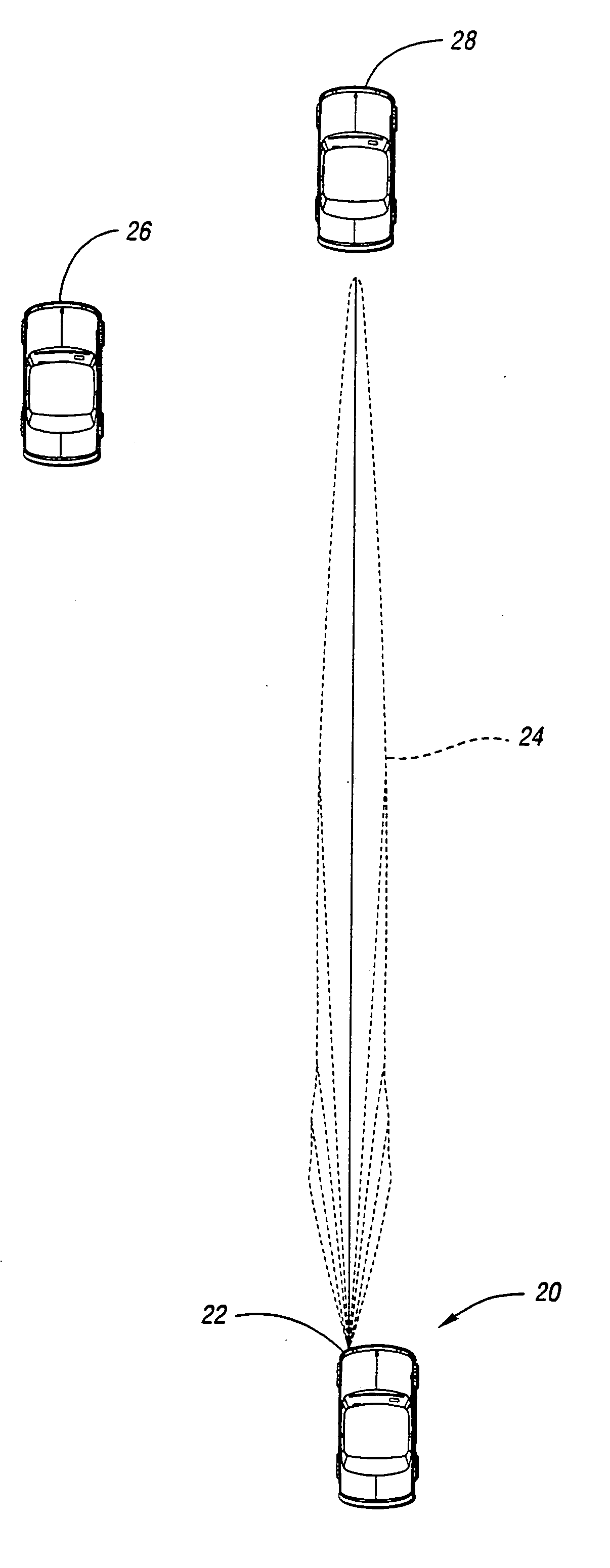

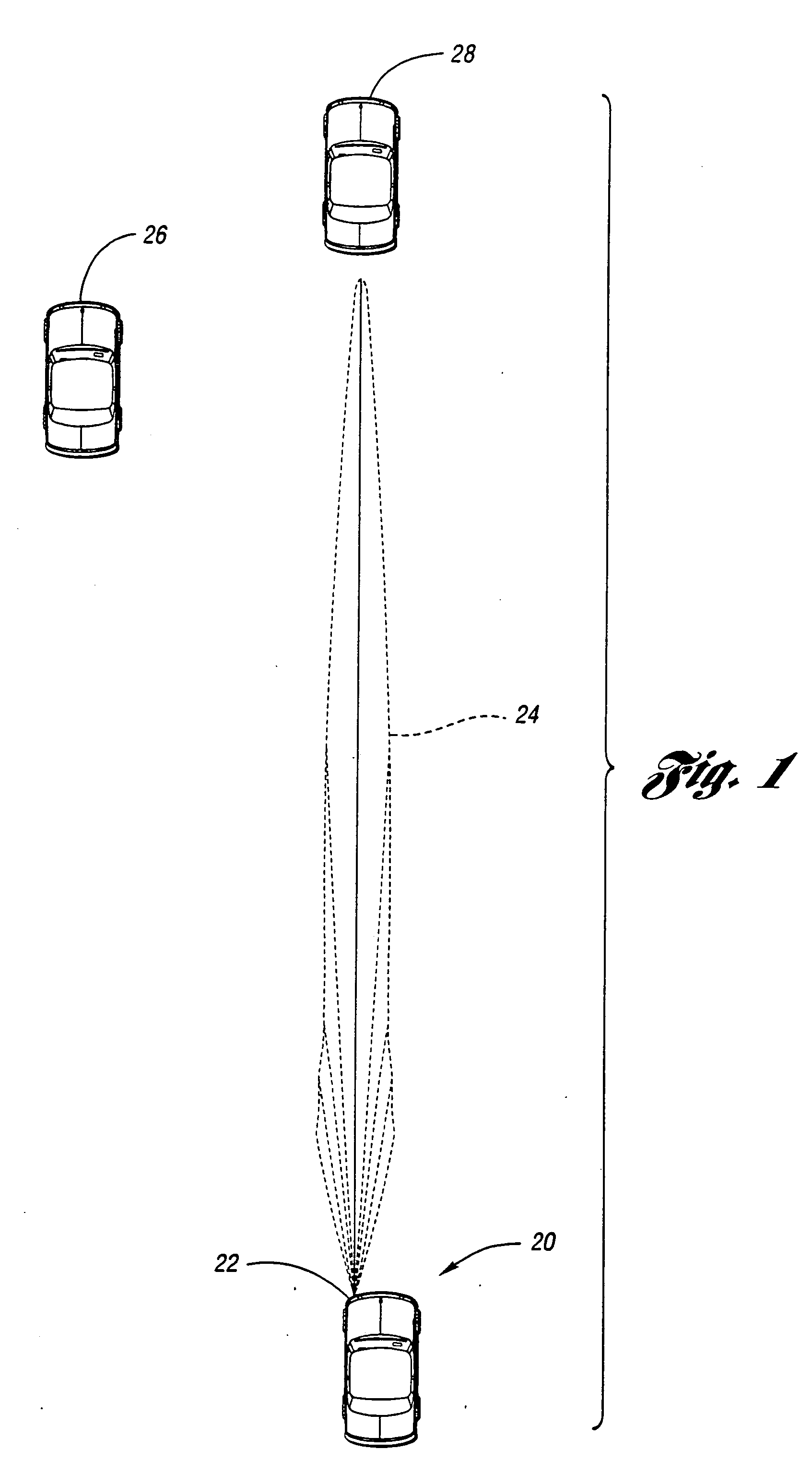

[0060] Referring now to FIG. 1, a continuously variable headlamp illumination range together with oncoming and leading vehicles is shown. Controlled vehicle 20 includes at least one continuously variable headlamp 22. Each headlamp 22 produces a variable region of bright light known as illumination range 24. A driver in oncoming vehicle 26 or leading vehicle 28 that is within illumination range 24 may view headlamps as producing excessive glare. This glare may make it difficult for the driver of oncoming vehicle 26 or leading vehicle 28 to see objects on the road, to read vehicle instruments, and to readjust to night viewing conditions once vehicle 26, 28 is outside of illumination range 24. Hence, illumination range 24 is perceived as a glare area by the driver of oncoming vehicle 26 or leading vehicle 28.

[0061] The present invention attempts to reduce the level of glare seen by the driver of oncoming vehicle 26 or leading vehicle 28 by providing a control system that detects oncom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com