Pallet rack

a pallet rack and pallet technology, applied in the field of pallet racks, can solve the problems of increasing the time and labor associated with assembling the pallet rack, the connection structure used to connect the frames to the upper and lower pallets is in general very complex and requires many individual parts, and the standard warehouse-type pallet cannot be incorporated into the pallet rack, so as to reduce the number of different parts required, simplify the assembly of the pallet rack, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

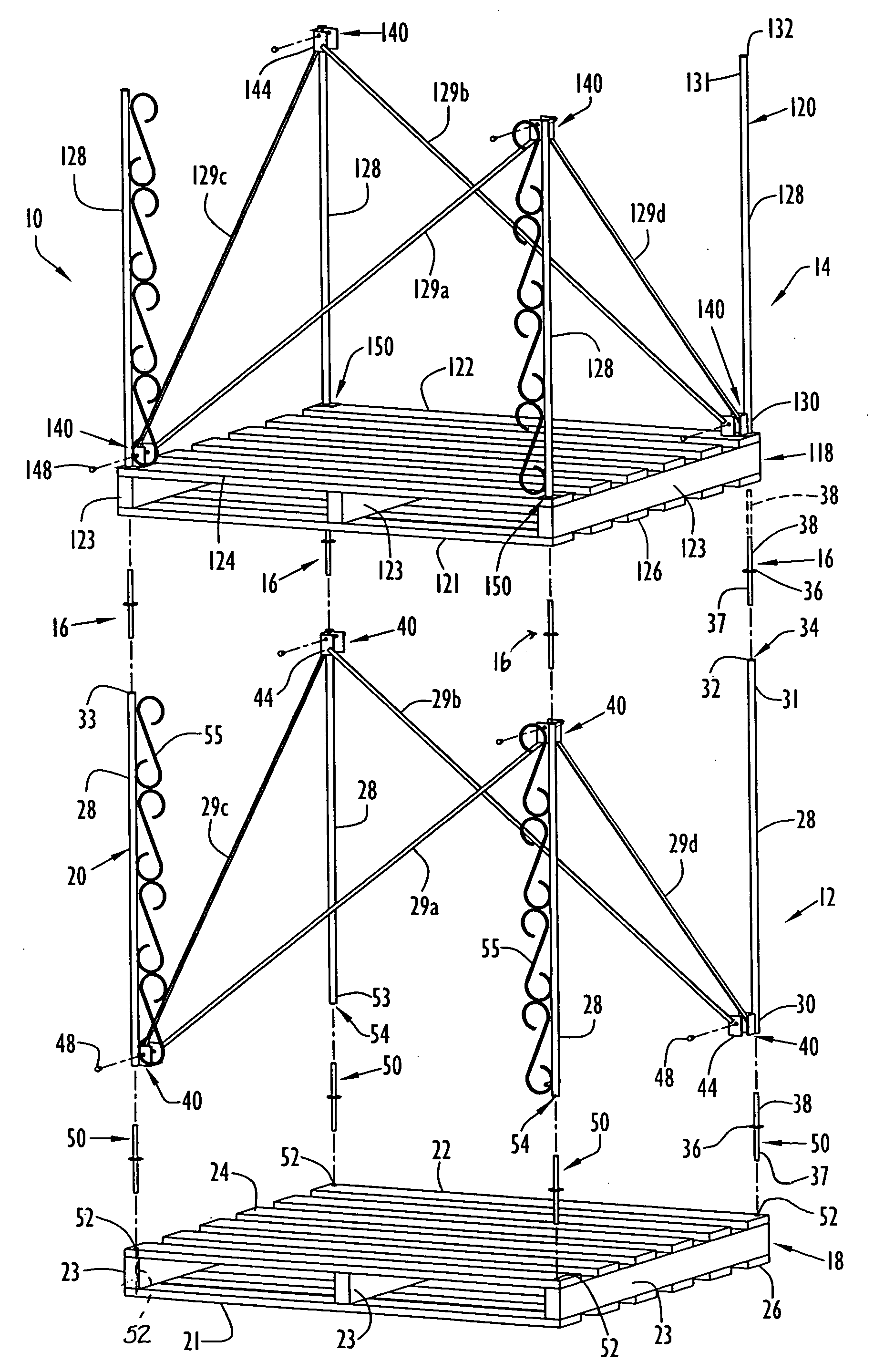

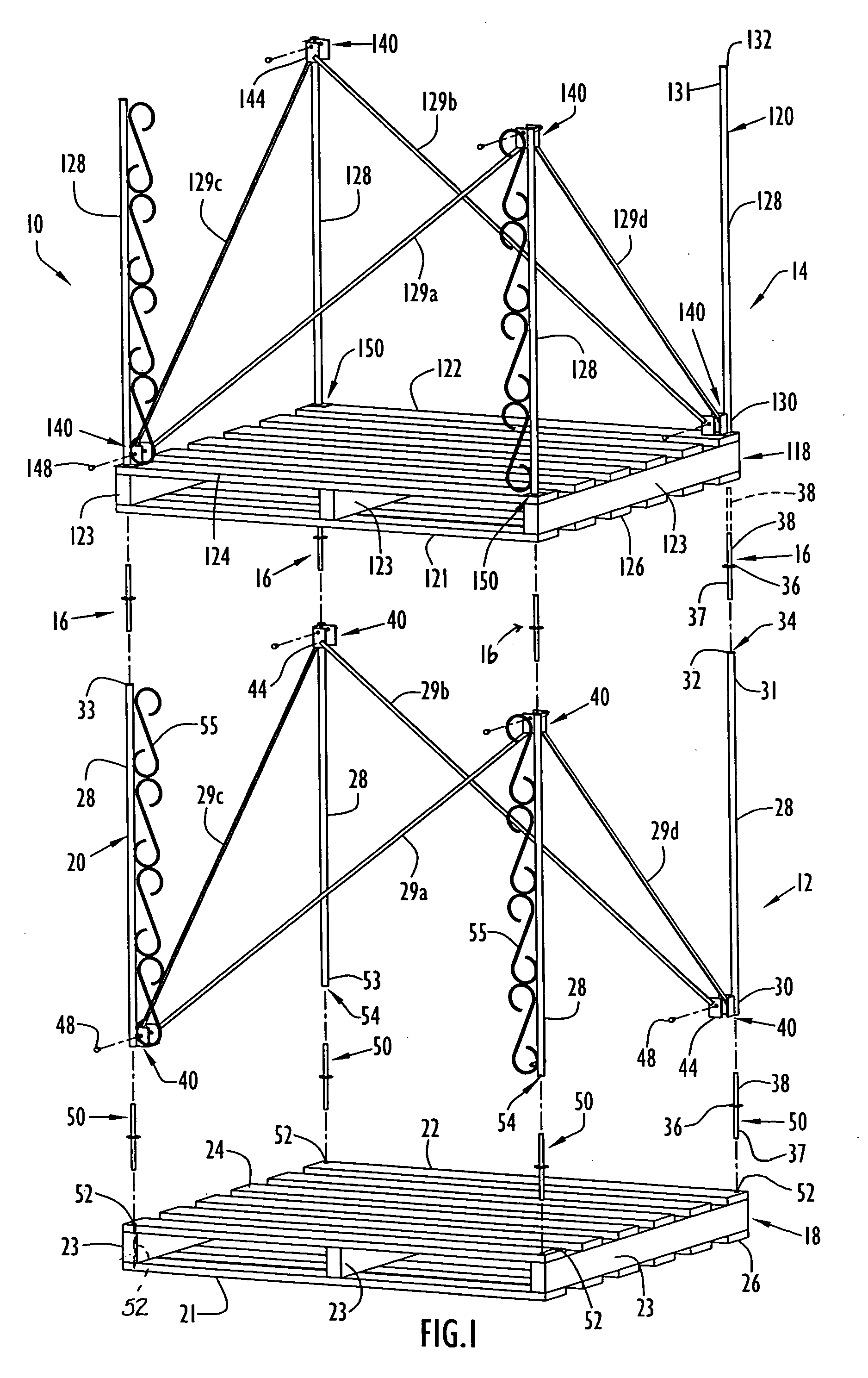

[0029] A pallet rack 10 according to the present invention is illustrated in FIG. 1 in an unassembled condition. The pallet rack 10 comprises a lower pallet unit 12, an upper pallet unit 14 and a plurality of connectors 16 for connecting the upper pallet unit 14 in supporting relation on the lower pallet unit 12. The lower pallet unit 12 comprises a lower pallet 18 and a frame 20 attached to the lower pallet 18. The lower pallet 18 has a lower surface 21 for being supported on the ground, floor or other support surface and an upper surface 22 on which one or more various objects may be supported. The lower pallet 18 may have a perimeter or footprint of square or nearly square configuration defining four corners. The lower pallet 18 may be a conventional warehouse-type pallet comprising a plurality of stringers 23 and an upper deck 24 secured to and supported on top sides of the stringers 23. The stringers 23 may be boards having a length, width and thickness, with the width of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com