Flexo processor

a flexo processor and processor technology, applied in multicolor photographic processing, printing form reproduction, instruments, etc., can solve the problems of large size and shape, requiring substantially larger and more expensive equipment, system can only be used with flat plates, additional machines and more time, etc., and achieve the effect of greater flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

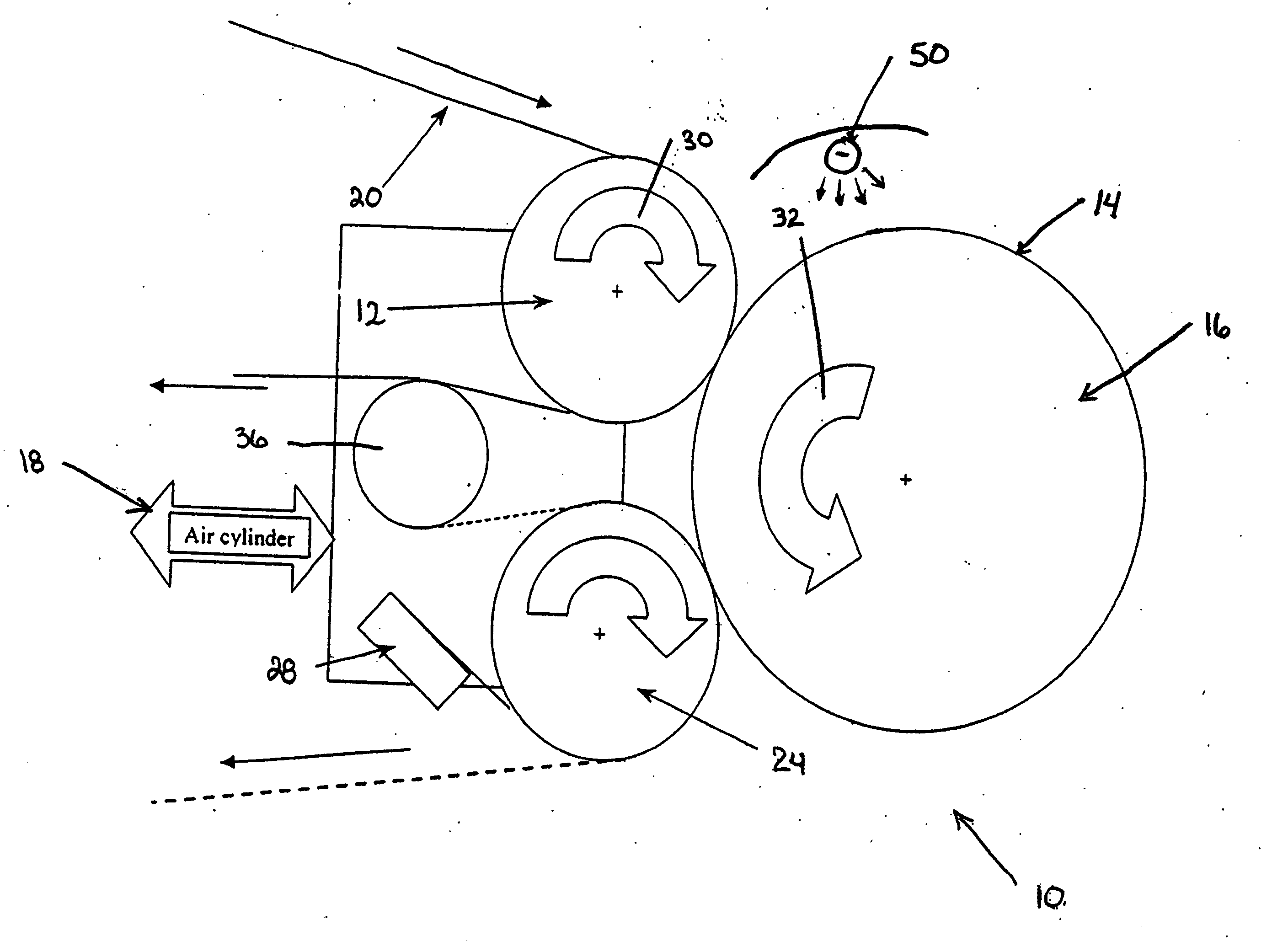

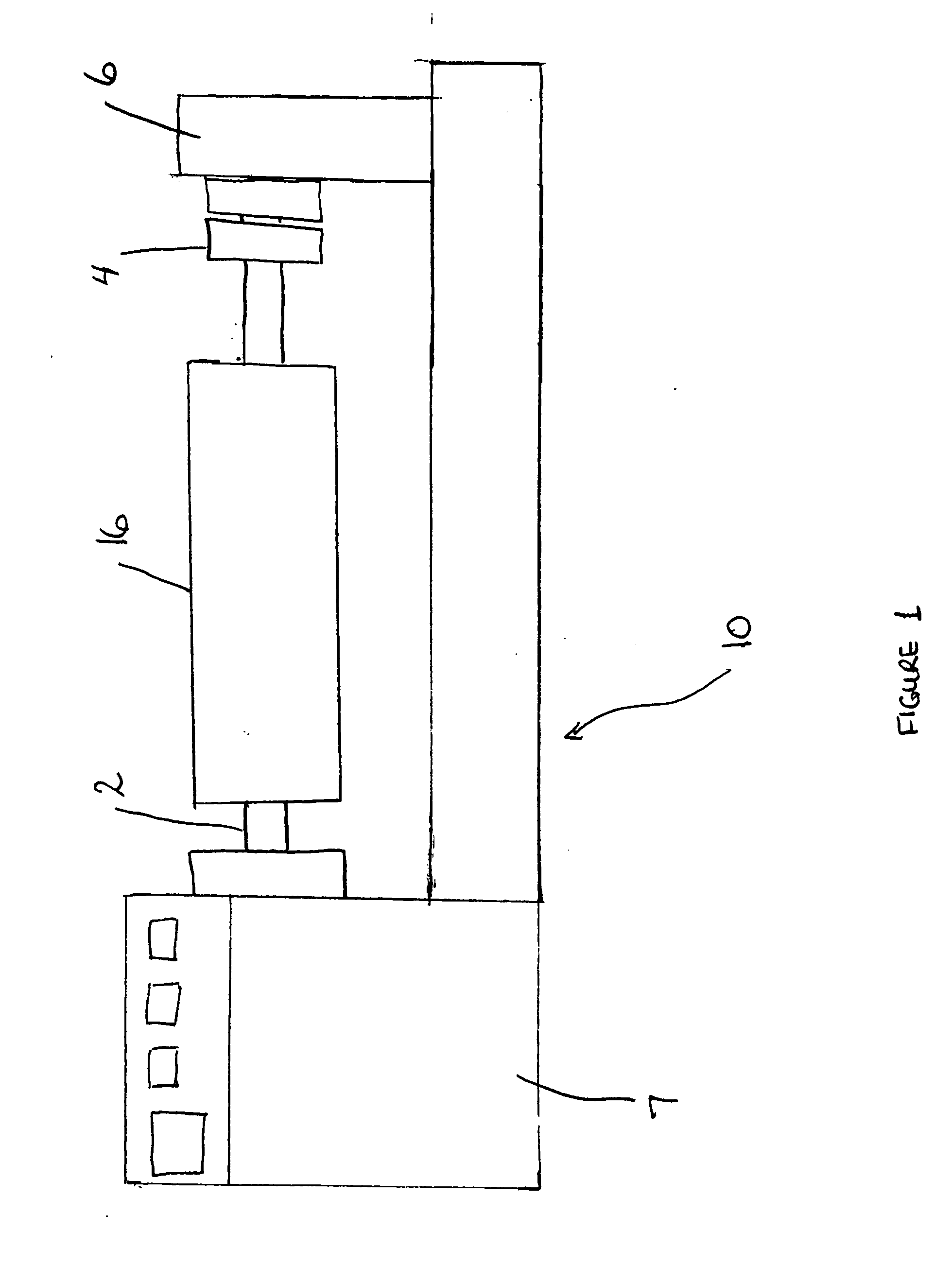

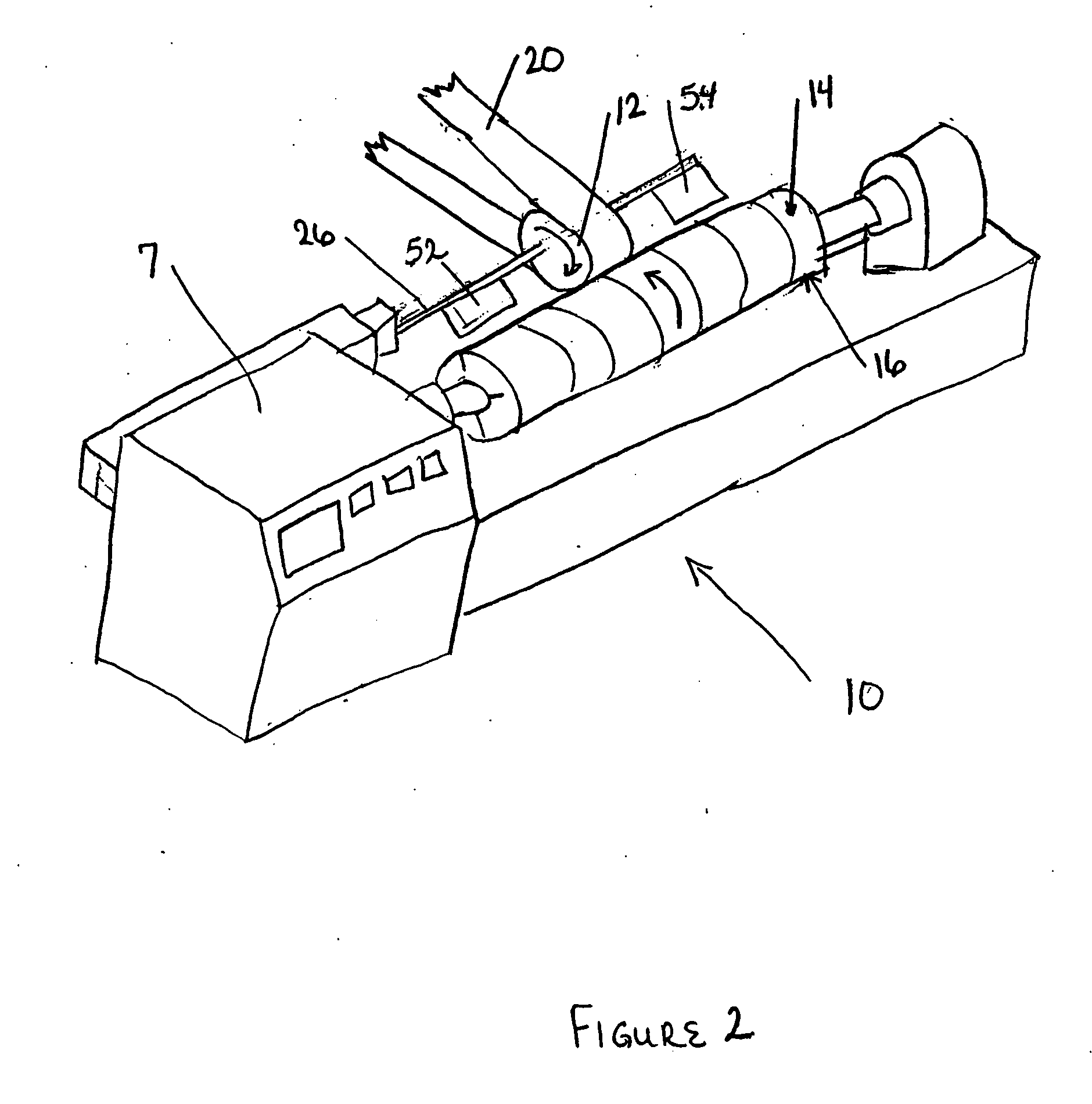

[0038] The present invention is directed to an improved thermal flexo processor that can be used to process both flat plates and CITR printing elements, and which has the further advantage of being easily scaled up or down in size by the manufacturer. One of the drawbacks to most flexo plate processors is that they are limited by the length of the cylinder on which the printing element is mounted. Therefore, a key advantage to the novel flexo plate processor of the invention is that that printing elements of various sizes and shapes can be processed.

[0039] The present invention is directed to a single machine designed with spacers of various sizes that can be added to the machine to make it longer and therefore capable of processing a broader range of plate sizes. Because a plate processor with such a design is limited only by the length of the mandrel or cylinder used, it is easy to use a similar machine design across a wide range of machine sizes. This is possible because the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| photosensitive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com