Singlestage and multistage electromagnetic revolutionary piston pump

a revolutionary, piston pump technology, applied in the field of piston pumps, can solve the problems of increasing working cost, reducing work efficiency, and affecting the operation of the whole system, so as to reduce the number of pump parts used and the size of the pump, and improve the airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

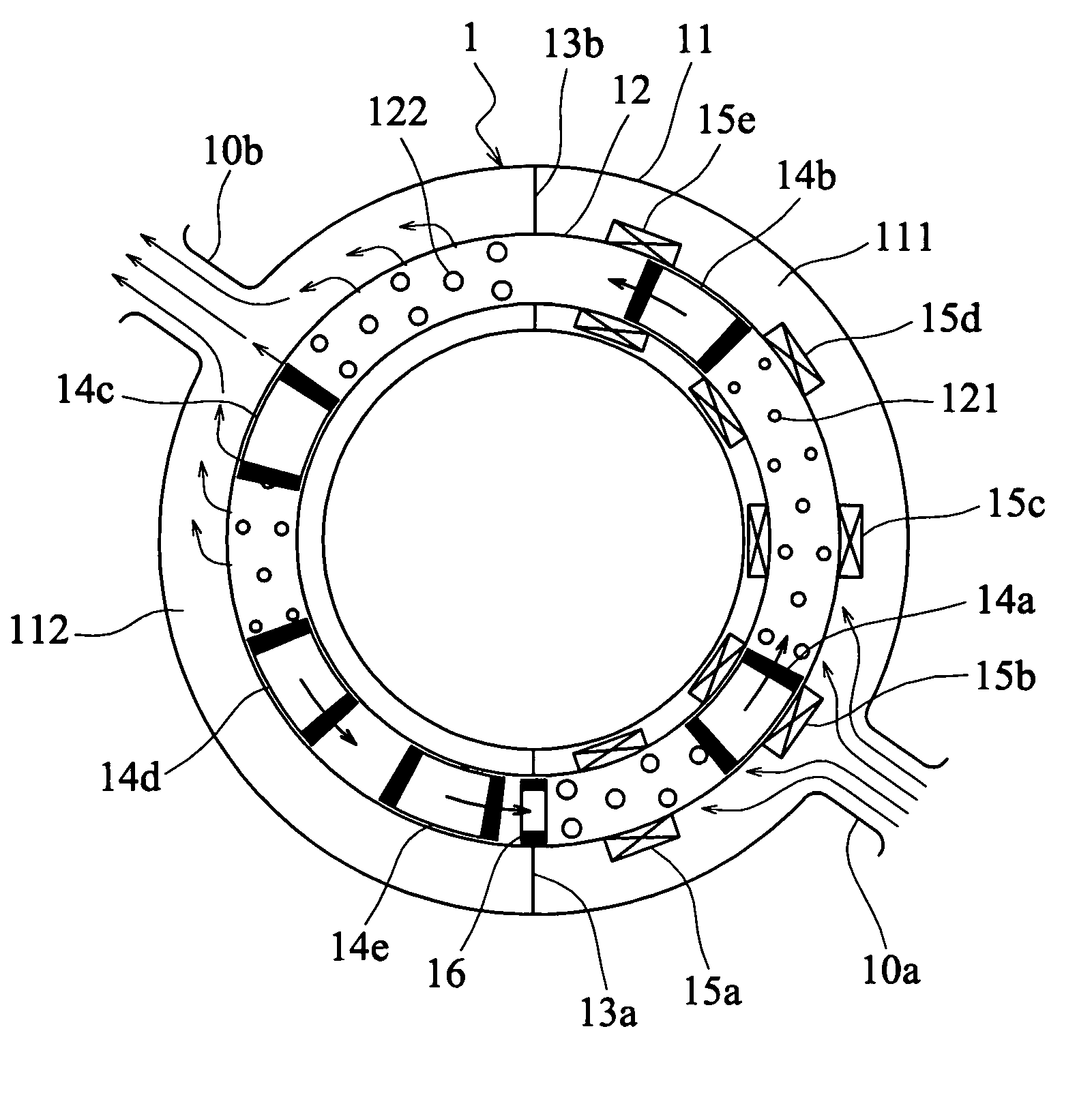

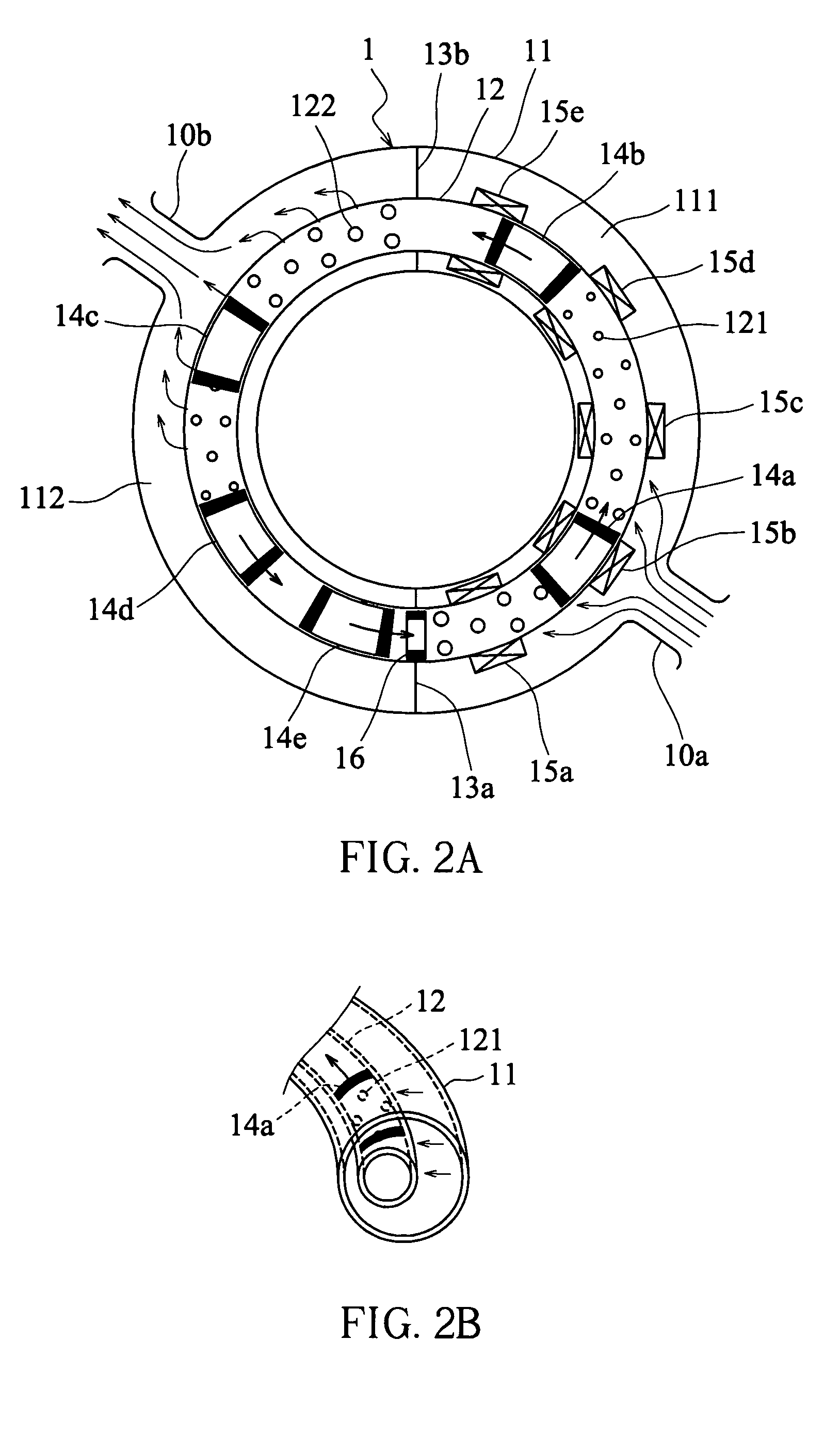

[0026] Referring to FIG. 2A and FIG. 2B, in a first embodiment, an electromagnetic revolutionary piston pump 1 includes a plastic outer doughnut tube 11, a copper inner doughnut tube 12, two annular separation plates 13a and 13b, five pistons 14a to 14e, and five sets of electromagnetic coils 15a to 15e.

[0027] The inner doughnut tube 12 is wrapped inside the outer doughnut tube 11, and the inner doughnut tube has a plurality of through holes 121 and 122 arranged on its' sidewall. The two annular separation plates 13a and 13b are placed inside the outer doughnut tube 11 but outside the inner doughnut tube 12, dividing the inner space of the outer doughnut tube 11 into two airproof spaces 111 and 112 that do not communicate with each other. The airproof space 111 connects an intake opening 10a closer to the annular separation plate 13a, and communicates with the space inside the inner doughnut tube 12 via the through holes 121. The airproof space 112 connects an exhaust opening 10b c...

second embodiment

[0035] Referring to FIG. 3, in a second embodiment, the airproof space 112 of electromagnetic revolutionary piston pump 1 can be further divided into 4 airproof spaces 113, 114, 115, and 116 by using other annular separation plates 13c, 13d, and 13e with the airproof spaces 113, 114, 115, and 116 connecting exhaust openings 10c, 10d, 10e, and 10f, respectively. In this way, one can get air with various pressures and airflows separately from the exhaust openings 10c, 10d, 10e, and 10f.

third embodiment

[0036] Referring to FIG. 4, in a third embodiment, a plurality of electromagnetic revolutionary piston pumps according to the invention can be connected in series to provide higher pressure of multistage and more airflow. For example, the exhaust opening of an electromagnetic revolutionary piston pump 1 is connected to the intake opening of an electromagnetic revolutionary piston pump 2, and the exhaust opening of the electromagnetic revolutionary piston pump 2 is connected to the intake opening of an electromagnetic revolutionary piston pump 3, and so on.

[0037] Since the pistons of the invention revolve inside the inner doughnut tube continuously, the invention can therefore generate continuous pressure without a backpressure valve and have the same pressure range as a conventional reciprocating pump. In addition, since the loss of magnetic energy in the invention relates only to the friction between pistons and the tube wall during the acceleration process, the loss of the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com