Insulation system with variable position vapor retarder

a technology of vapor retarder and insulation system, which is applied in the field of insulation system, can solve the problem of small amount of condensation within the insulation system, and achieve the effect of reducing the amount of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

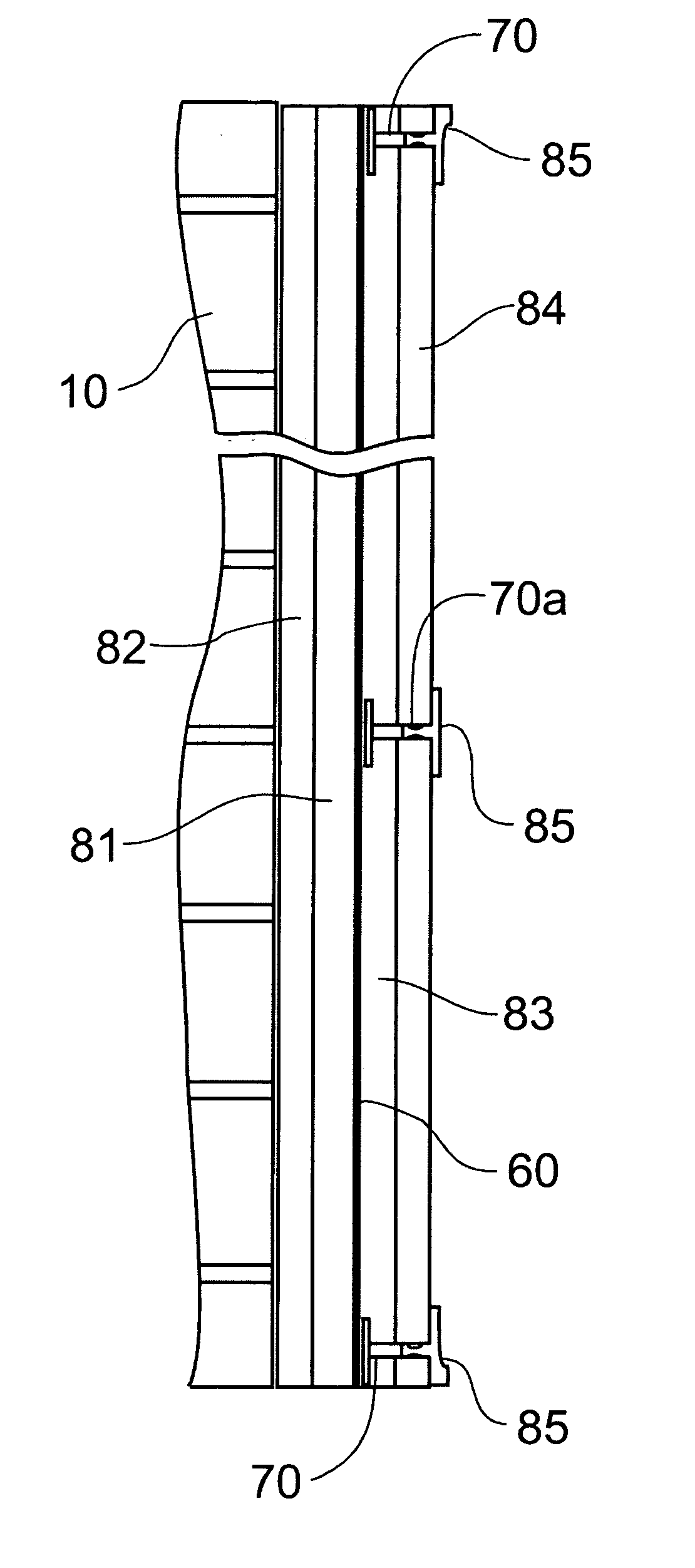

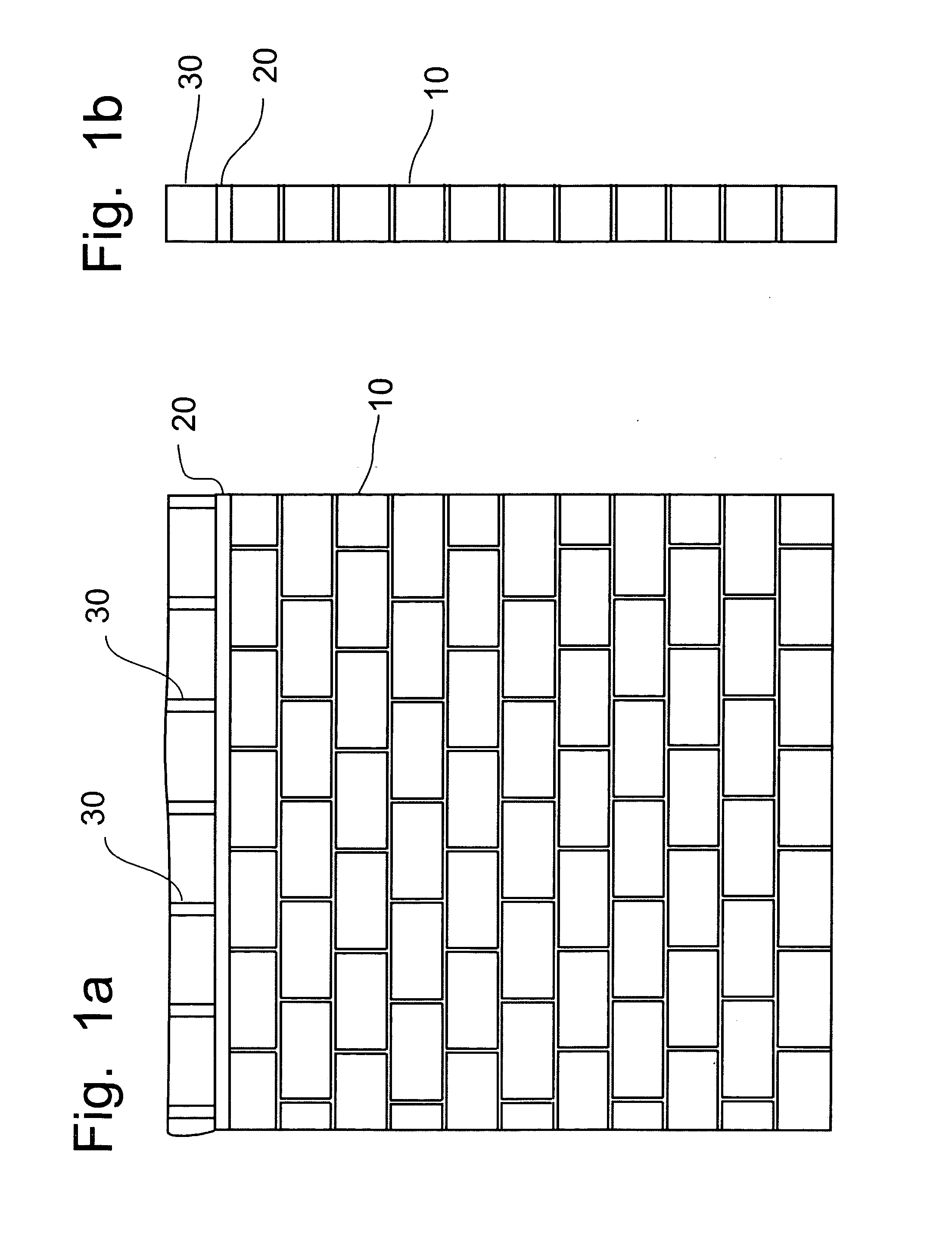

Image

Examples

example

[0062] Determination of the Optimal Placement of a Vapor Retarder in Columbus, Ohio Based on Condensation Potential

[0063] Five separate experimental insulation systems are constructed in Columbus, Ohio, each experimental system having R-13 insulation placed a concrete block wall with a vapor retarder placed on or within the insulation at a chosen location. Each of the five experimental insulation systems are discussed in detail below and are shown schematically in FIGS. 8a, 9a, 10a, 11a, and 12a. The interior of the building for each of the experimental systems has a temperature of 65° F. and a relative humidity of 40%.

[0064] The outside temperature and the outside dew point temperature on both Jan. 1, 2002 and Aug. 1, 2002 are obtained, such as from hourly climatic data, and the temperature of the vapor retarders in each of the experimental systems are calculated. Graphs for the data for each of the five experimental systems are depicted in FIGS. 8b-8c, 9b-9c, 10b-10c, 11b-11c, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com