Weather strip

a weather strip and weather strip technology, applied in the field of weather strips, can solve the problems of warp production of weather strips and worse installation workability, and achieve the effect of increasing rigidity and easy fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] An embodiment of the invention will now be described by reference to the drawings.

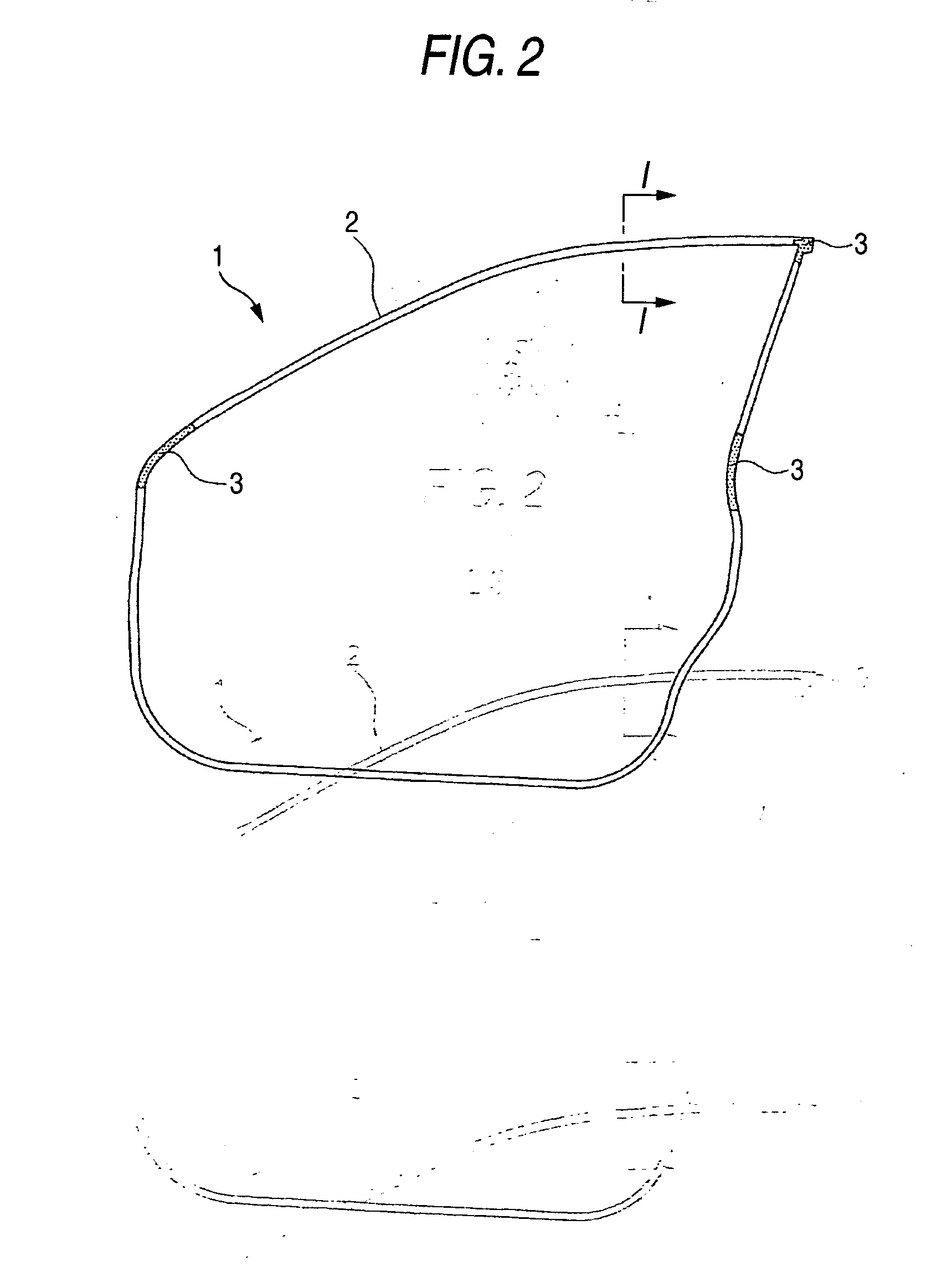

[0035] Automobiles are provided with open-and-close front doors and a weather strip 1 is installed along the outer periphery of such a front door as shown in FIG. 2. The greater part of the weather strip 1 along the longer direction is formed by an extrusion molding portion 2. Moreover, corner portions (with point patterns in FIG. 2) are formed with die-molded sections 3.

[0036] As a portion corresponding to the roof side portion (upper side portion of FIG. 2) out of the extrusion-molded portion 2 has a distinctive feature according to the embodiment of the invention, the construction of the portion in question will be described as follows.

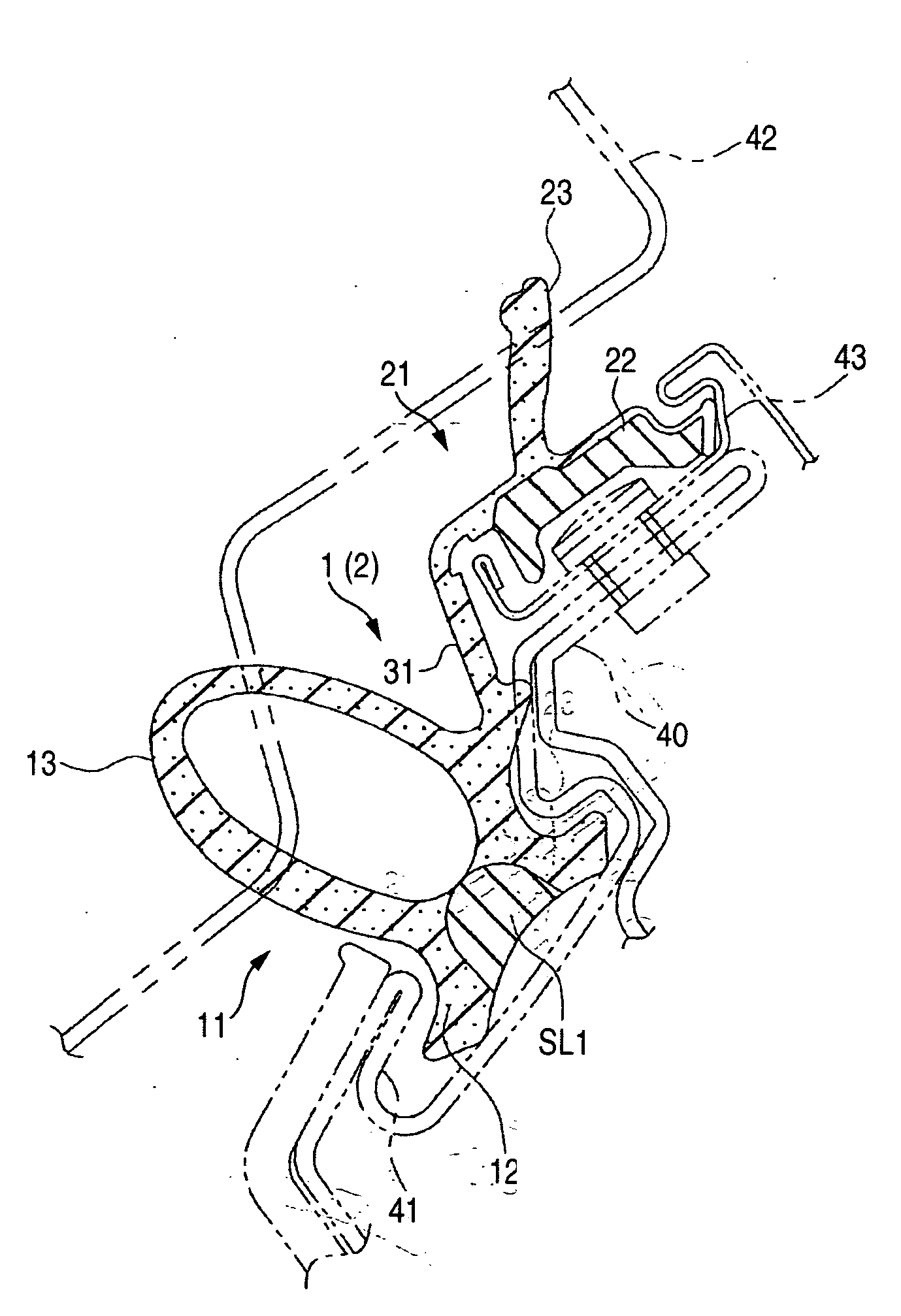

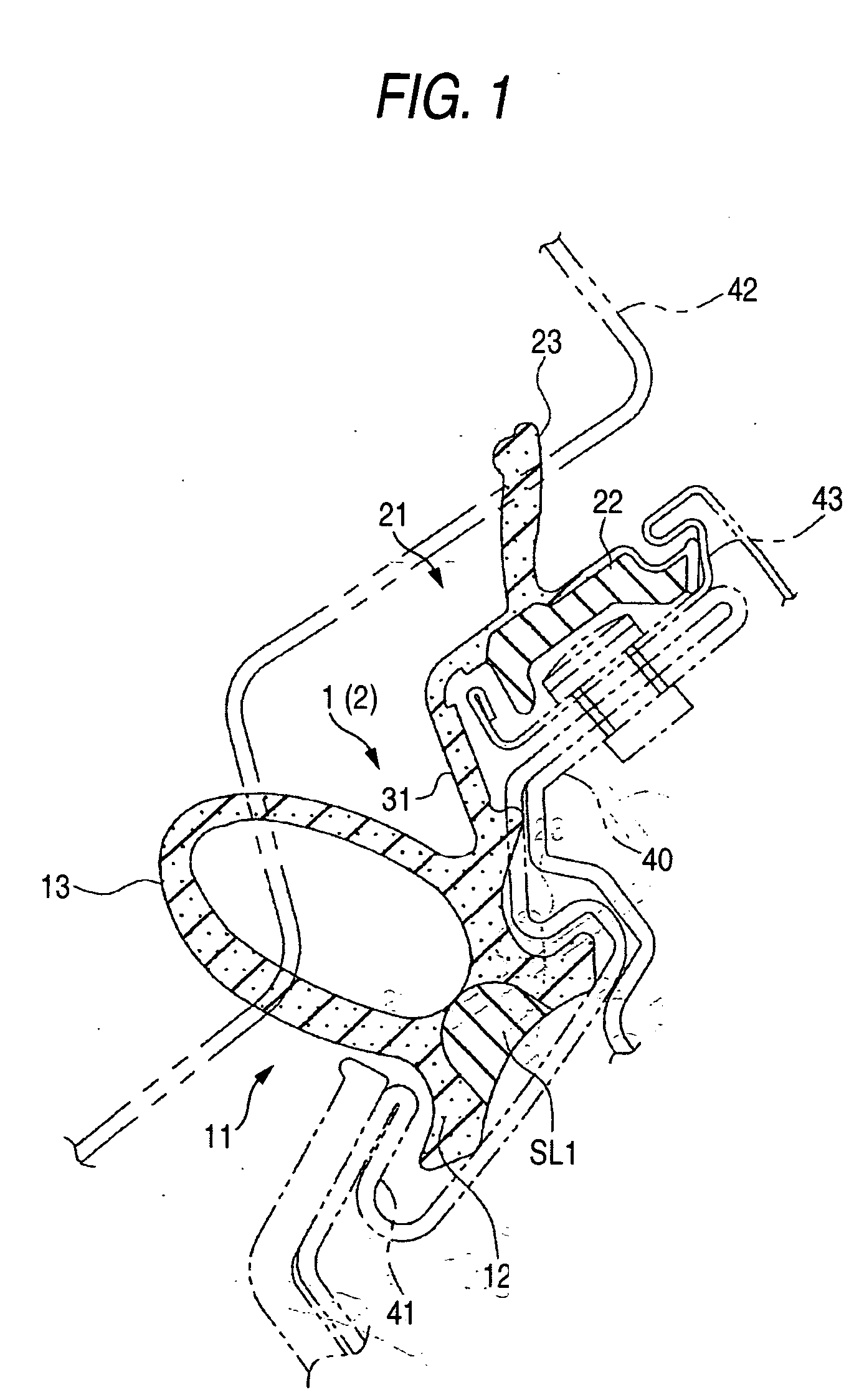

[0037] As shown in FIG. 1, the extrusion-molded portion 2 in the upper side portion has a main seal member 11 as a first seal member, a sub-seal member 21 as a second seal member and a coupling portion 31 for coupling both the seal members 11 and 21.

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com