Container for retaining liquids and valve for use in the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0045] the valve of the present invention is shown in FIGS. 11-16 and is generally indicated at 120. Valve 120 comprises a generally frusto-conical housing 170 and a stud 171 which are snap-fitted together and which lock the shaft 118a of a straw 118 therebetween. As may be seen from FIGS. 13 and 14, housing 170 has a longitudinal axis S-S′ and defines an interior tapered cavity 172 which is accessed through a first aperture 173 at one end and through a second, narrower aperture 174 at the other end. A plurality of flanges 175 are axially arranged around the interior wall 176 of housing 170. Interior wall 176 further includes an annular shoulder 177 formed a spaced distance inwardly of aperture 173 and an annular stop 178 formed proximate aperture 174. A plurality of axial apertures 168 may be provided in housing 170.

[0046] Referring to FIGS. 15 & 16, stud 171 comprises a generally cylindrical base 179 with a central plug 144 extending outwardly therefrom and along the longitudinal ...

fourth embodiment

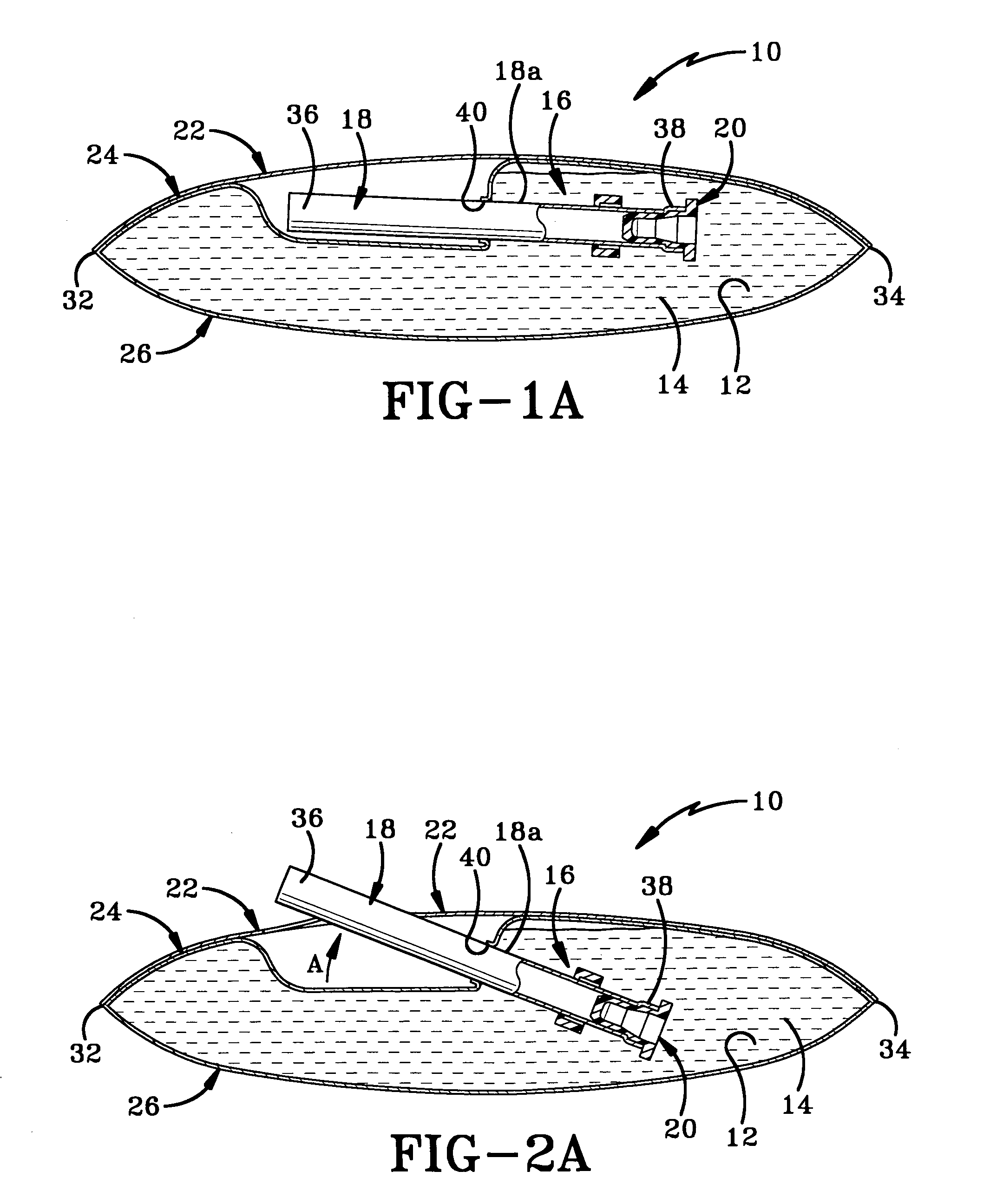

[0050] valve is shown in FIGS. 19 and 20 and is generally indicated at 320. All components of the pouch 310 are the same as with the pouch 10 except that valve 320 lacks a plug for blocking straw 318. Valve 320 comprises a sleeve into which second end 338 of straw 318 is slidably received. When the consumer wishes to use straw 318, they break through the perforations (not shown) in tear-away strip 322 in the manner previously described, grasp first end 336 of straw 318 and rotate the first end 336 upwardly in the direction of arrow “C” (FIG. 20). When valve 320 encounters interior surface 324a of first wall 324 and straw 318 is pulled upwardly in the direction of arrow “D”, valve 320 slides off second end 338 of straw 318 and liquid 314 can then flow into straw 318. It will be understood that second end 338 of straw 318 may be enlarged so that it cannot be easily withdrawn through aperture 340 in first wall 324. Furthermore, instead of completely removing second end 338 of straw 318...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angular velocity | aaaaa | aaaaa |

| Angular velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com