System and Method for Selective Communication with RFID Transponders

a selective communication and transponder technology, applied in the field of rfid communication systems, can solve the problems of reducing the system complexity and cost of anti-collision management, and affecting the safety of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

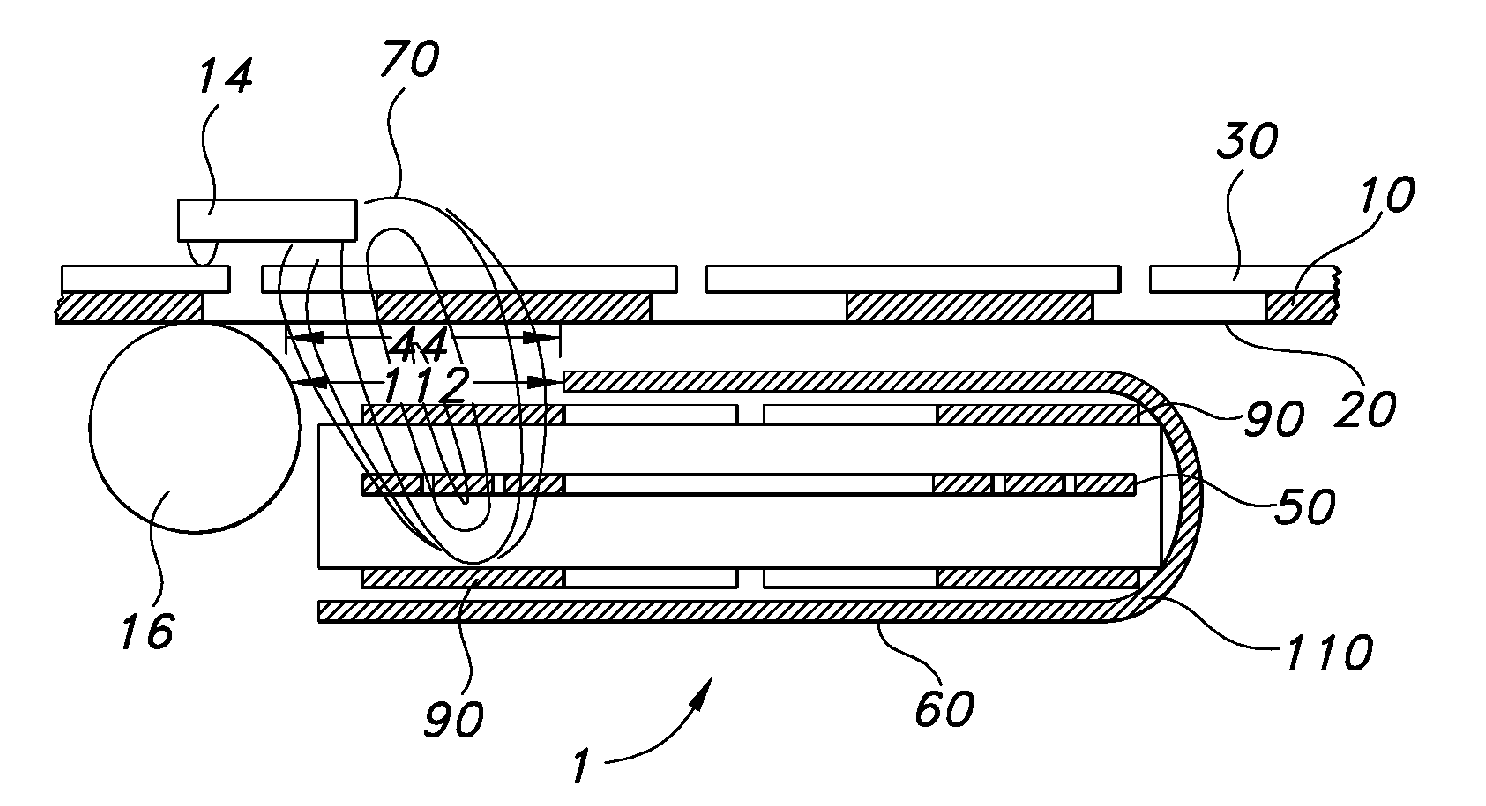

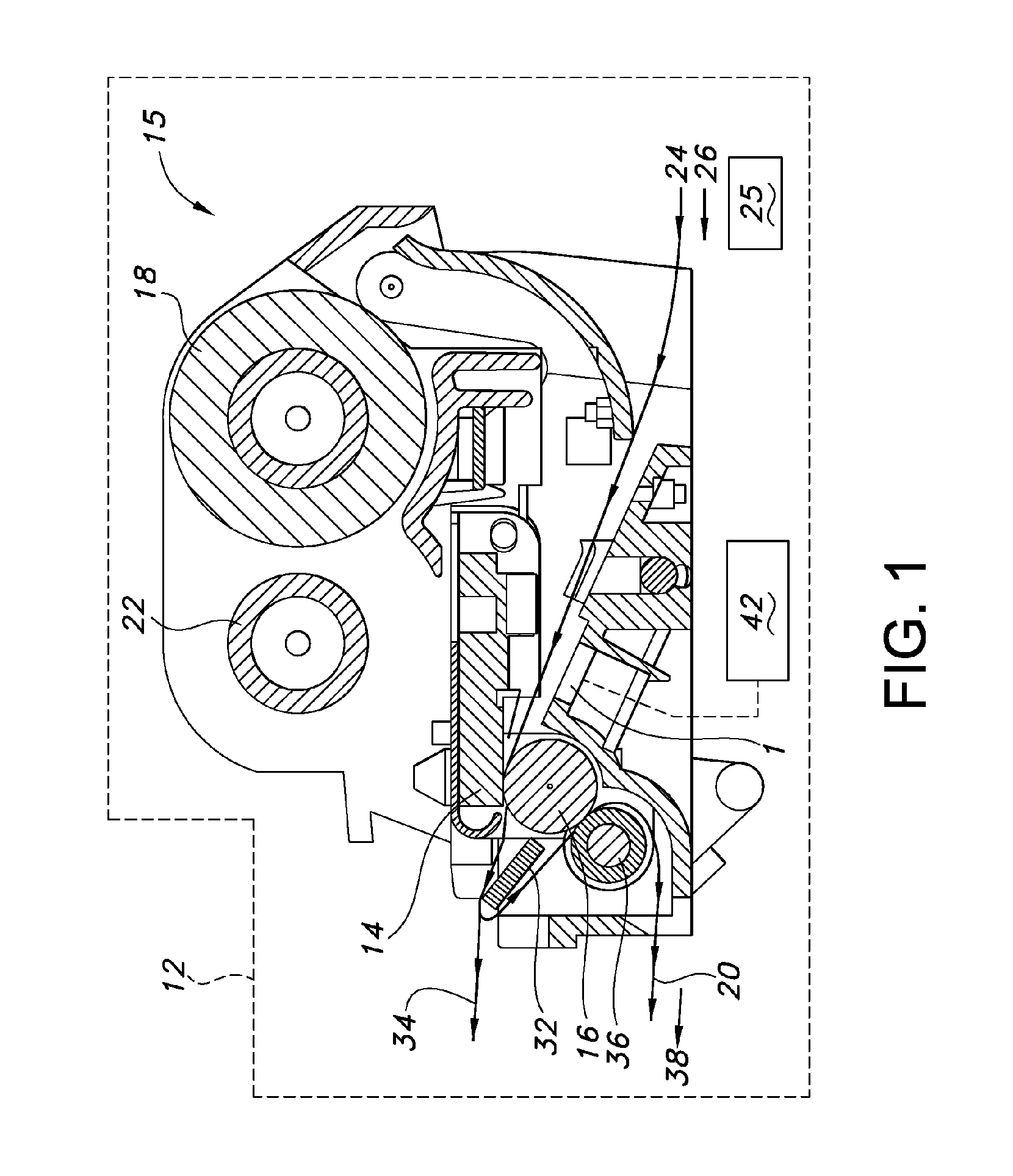

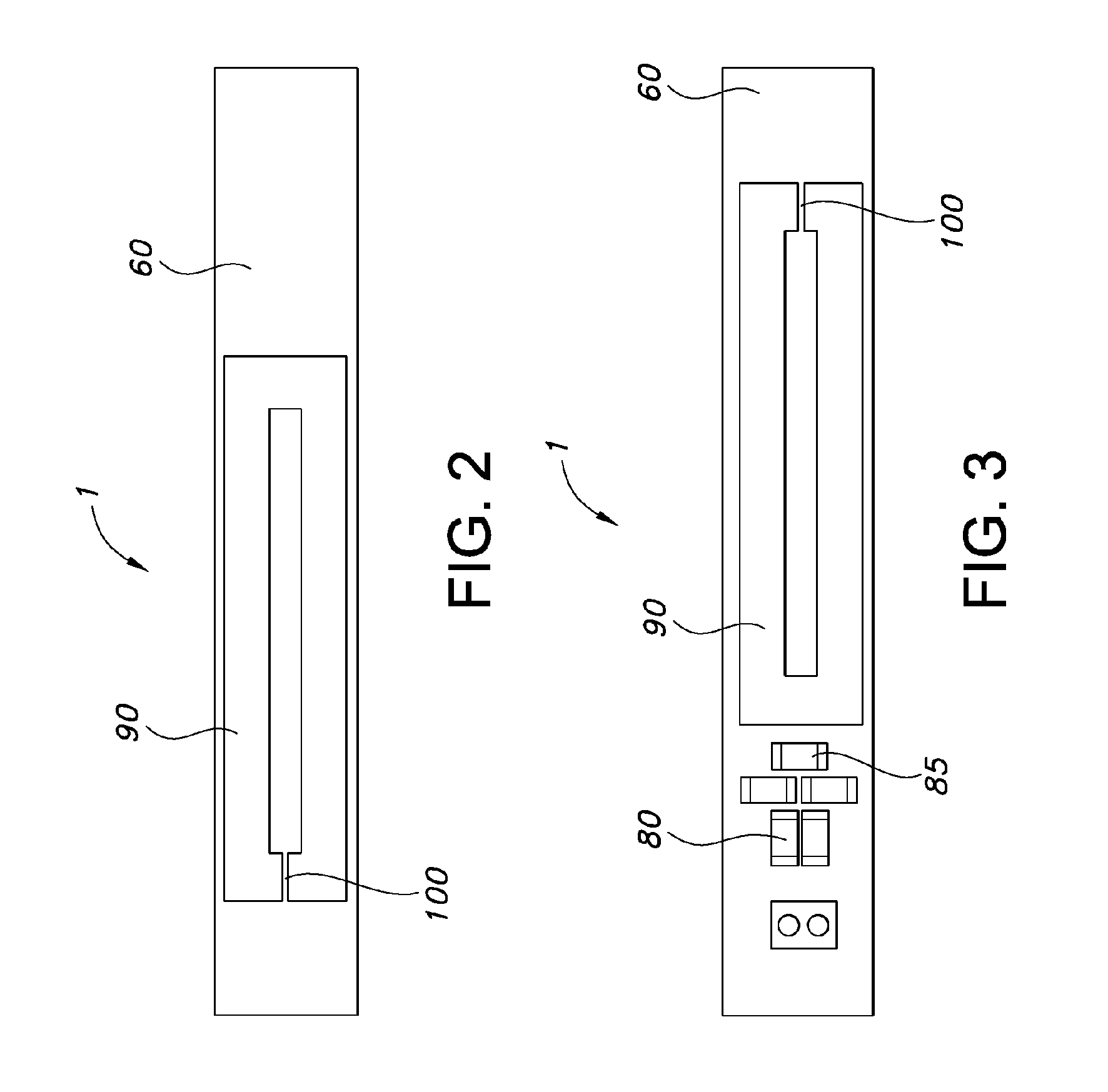

[0026] The present invention concerns apparatus and method which enables an RFID transceiver (sometimes termed herein an “interrogator”) to communicate selectively and exclusively with a single RFID transponder when one or more other transponders are in close proximity, without the need for physical isolation or cumbersome shielded housings or chambers.

[0027] The invention is useful in the loading or reading of transponders, for example on an assembly line, in distribution centers or warehouses where on-demand RFID labeling is required, and in a variety of other applications. In many applications a transponder or a number of transponders are mounted on a label, ticket, tag, card or other media carried on a liner or carrier. It is often desirable to be able to print on the media before, after, or during communication with a transponder. Although this invention is disclosed here in a specific embodiment for use with a direct thermal or thermal transfer printer, it may also be used wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com