Tray with flat bottom reference surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] While the present invention will be described herein with reference to particular embodiments thereof, a latitude of modifications, various changes and substitutions are intended, and it will be appreciated that in some instances some features of the invention will be employed without a corresponding use of other features without departing from the spirit and scope of the invention as described with respect to the preferred embodiments set forth herein.

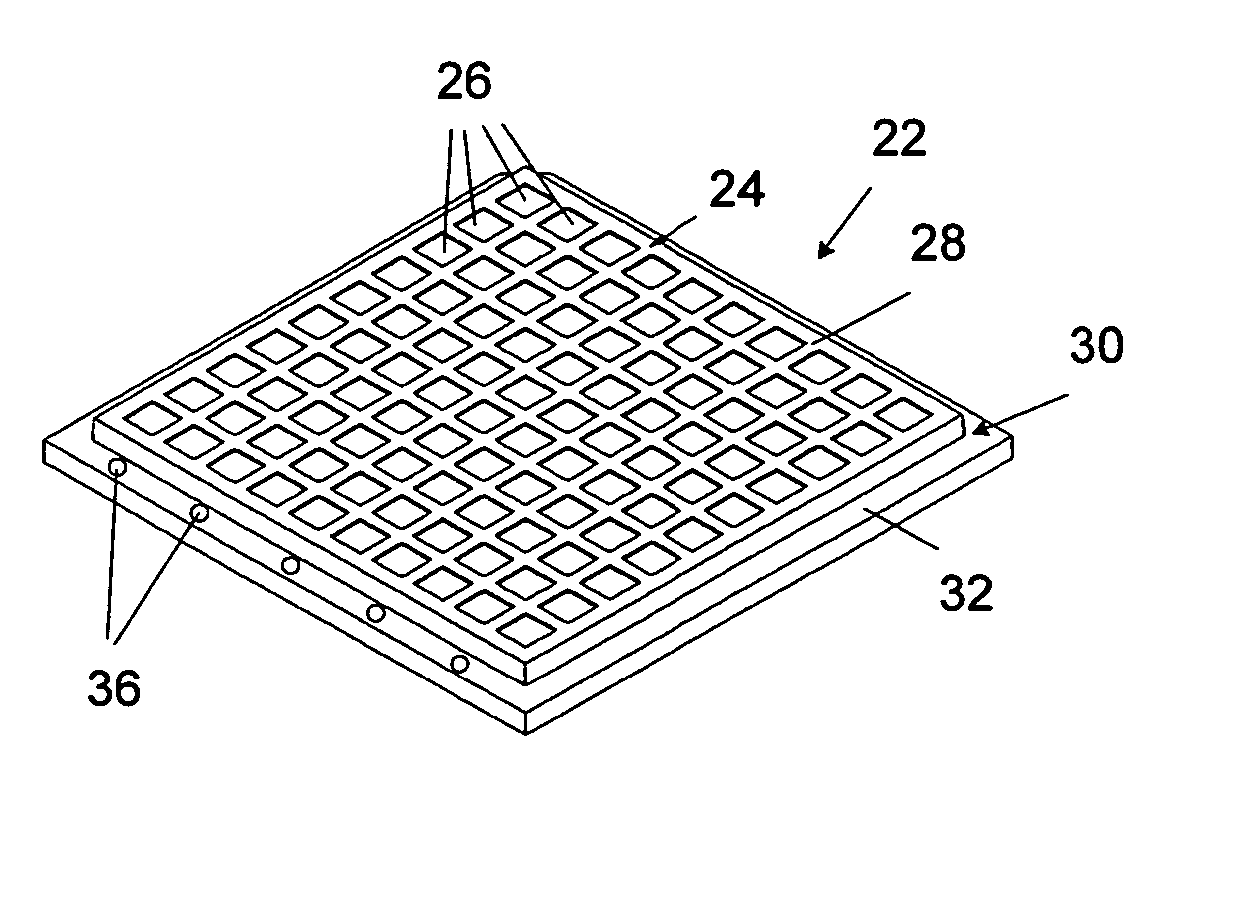

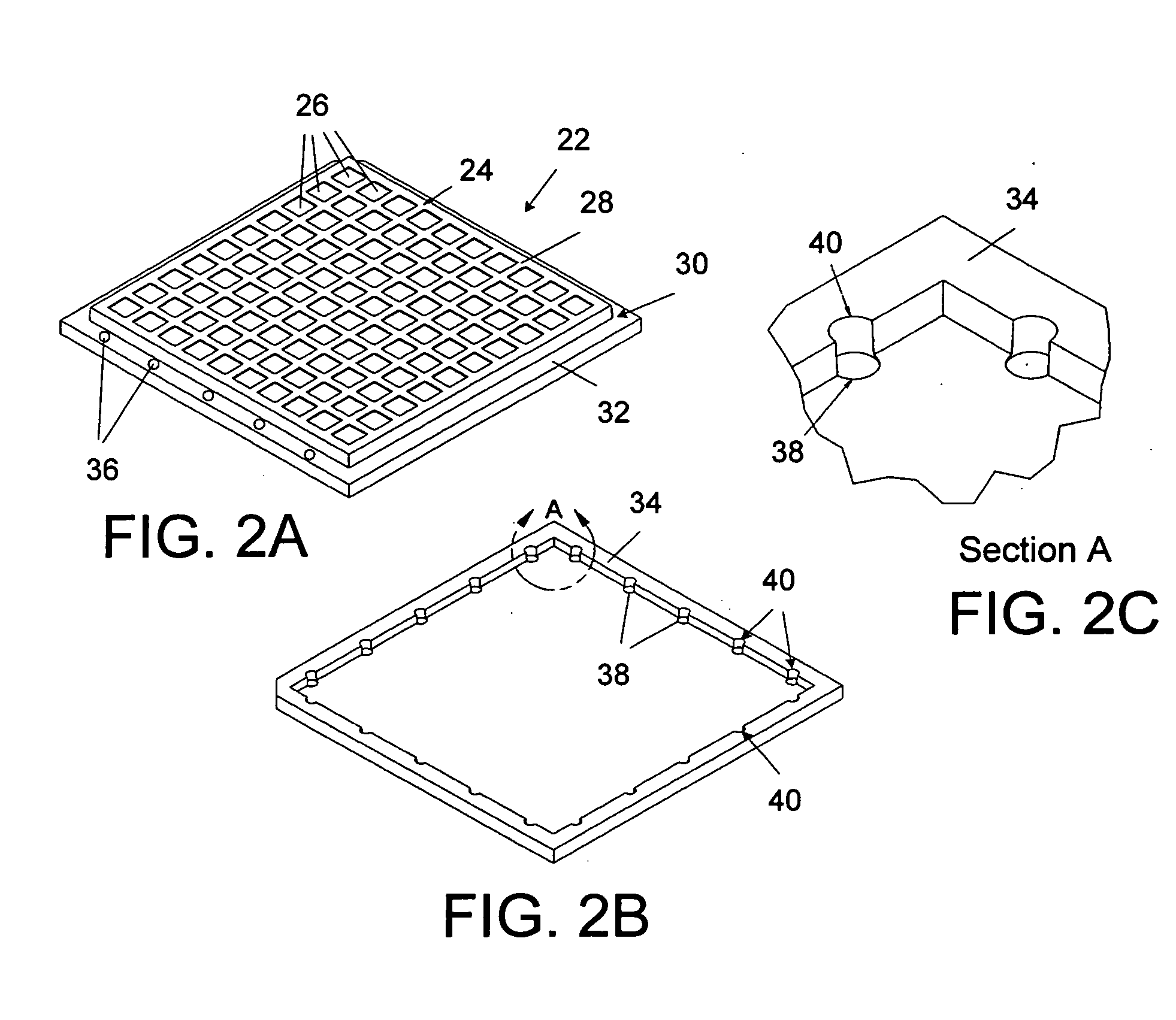

[0021] Referring now to FIGS. 2A and 2B, a component tray 22 is shown that has been formed in a mold. The tray 22 has a component housing portion 24, containing a plurality of component pockets 26 opening to top surface 28. The component pockets 26 are for holding small components, such as semiconductor devices. A flange 30 extends around the housing portion 24, defining the perimeter of the tray 22. The flange 30 has a flange top surface 32, and a bottom surface 34 shown in FIG. 2B. The flange alternatively can be of other co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com