Blending of economic, ether free winter gasoline

a technology of economic and winter gasoline, applied in the field of fuels, can solve the problems of difficult elimination of ether compounds and considerable obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

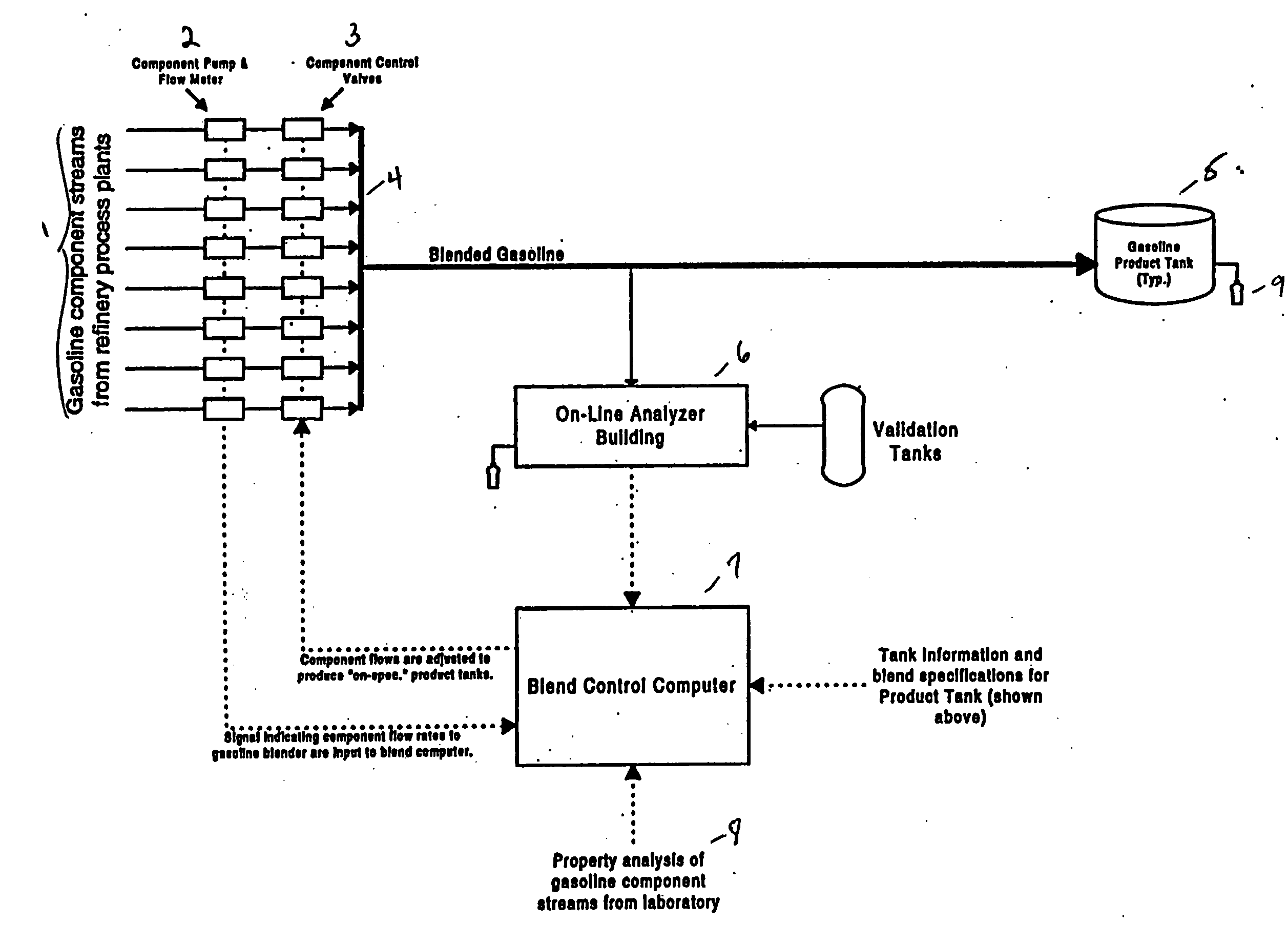

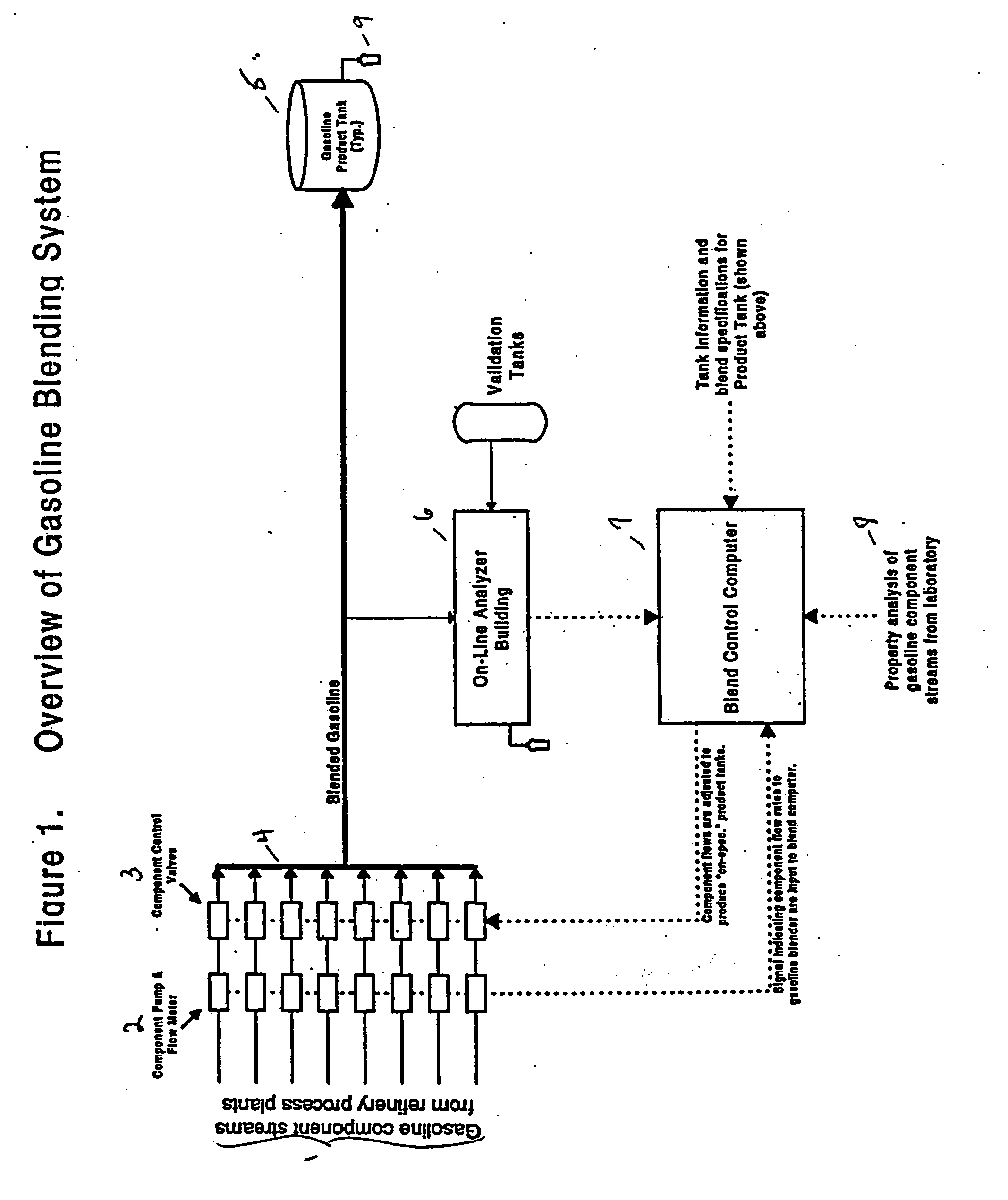

A number of different blended gasolines were made using the blending system depicted in FIG. 1, with an on-line analyzer. All of the various blended gasolines, Nos. 1-21, were made at different times using different component streams from a refinery. All of the blended gasolines, however, are deemed to be in compliance with both the California Phase 2 and Phase 3 Predictive Model.

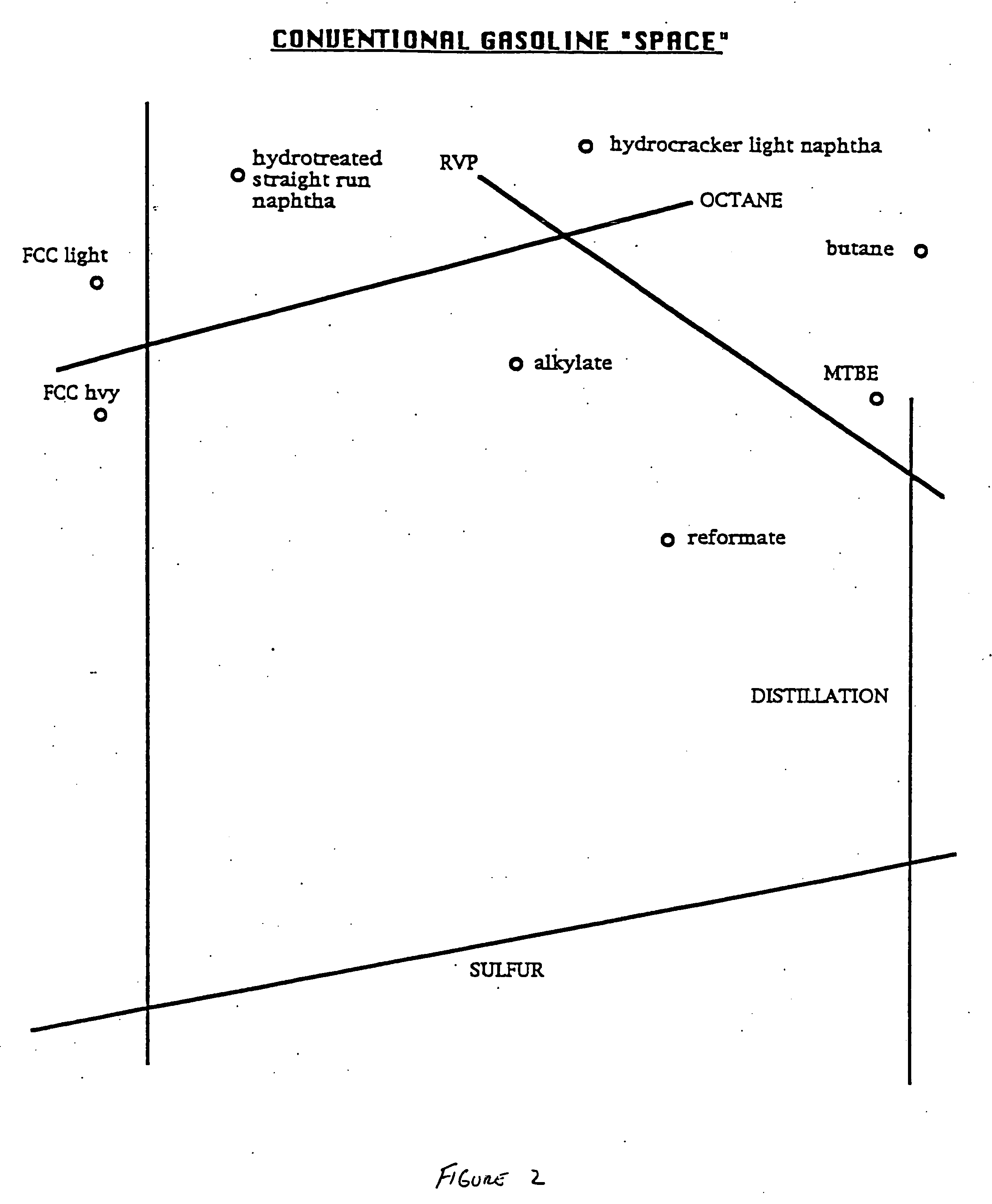

The various component streams used were conventional gasoline component streams including: (i) light petroleum-butane / pentane; (ii) pentane / hexane; (iii) hydrobate (reformer feed); (iv) reformate; (v) FCC gasoline; (vi) alkylate; (vii) toluene.

All of the foregoing component streams were provided from the same refinery. However, any one of the streams used, and particularly toluene, can be provided from an outside source, but it is preferred for the present invention that the component streams originate as streams in the refinery on site.

Provided below in Tables 3 and 4 are the qualities of eac...

example 2

A premium blend winter gasoline was prepared on a laboratory scale using normal butane, normal pentane, isopentane, toluene, reformate, FCC light, isomerate, rerun alkylate and whole alkylate as the components, with the properties being measured. Such a gasoline composition, as shown in Example 1, could also be prepared using the blending system of the present invention, i.e., as depicted in FIG. 1. The gasoline blend had the following qualities:

PUM

| Property | Measurement | Unit |

|---|---|---|

| vapor pressure | aaaaa | aaaaa |

| octane rating | aaaaa | aaaaa |

| vol. % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com