Washing machine

a washing machine and washing machine technology, applied in other washing machines, sustainable buildings, textiles and papermaking, etc., can solve the problems of ineffective use of electric energy supplied to the motor in many cases, insufficient consideration of the vibration characteristics of various washing machine mechanisms for the wash step, and insufficient torque developed by the motor to efficiently transmit to rotating objects including the motor rotor, etc., to achieve noise reduction, less vibration, and less vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described with reference to the accompanying drawings in order to be disclosed in more detail.

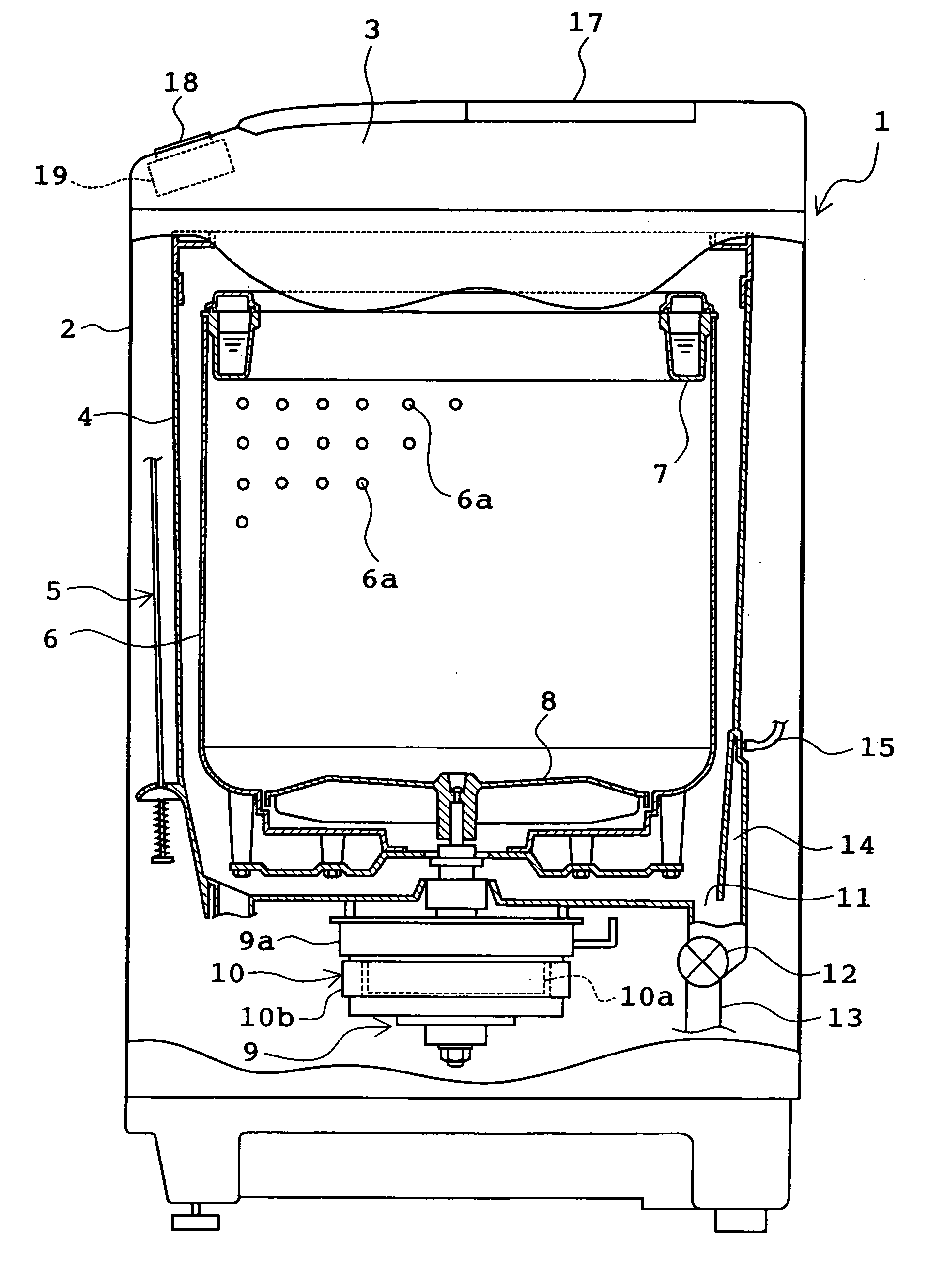

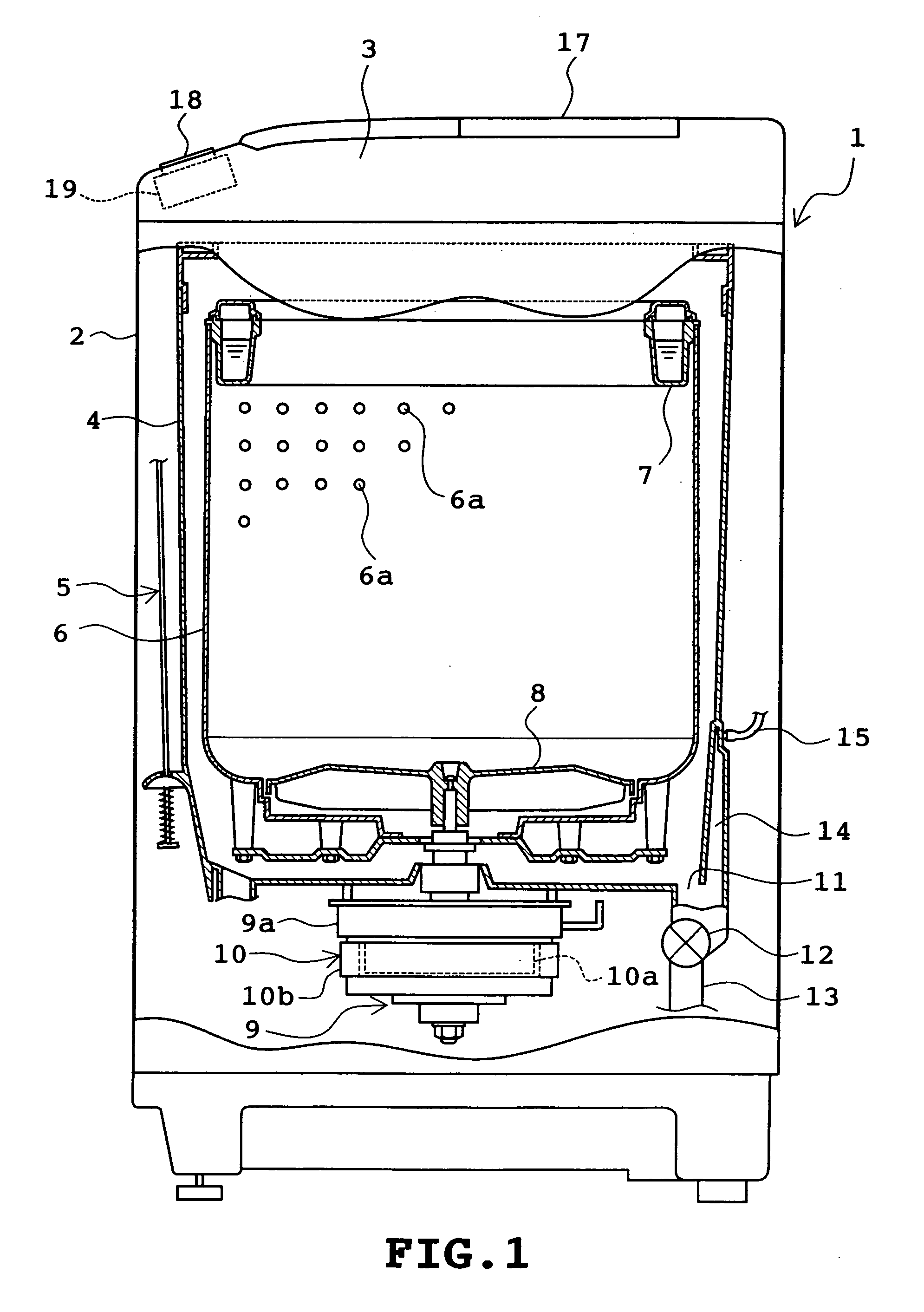

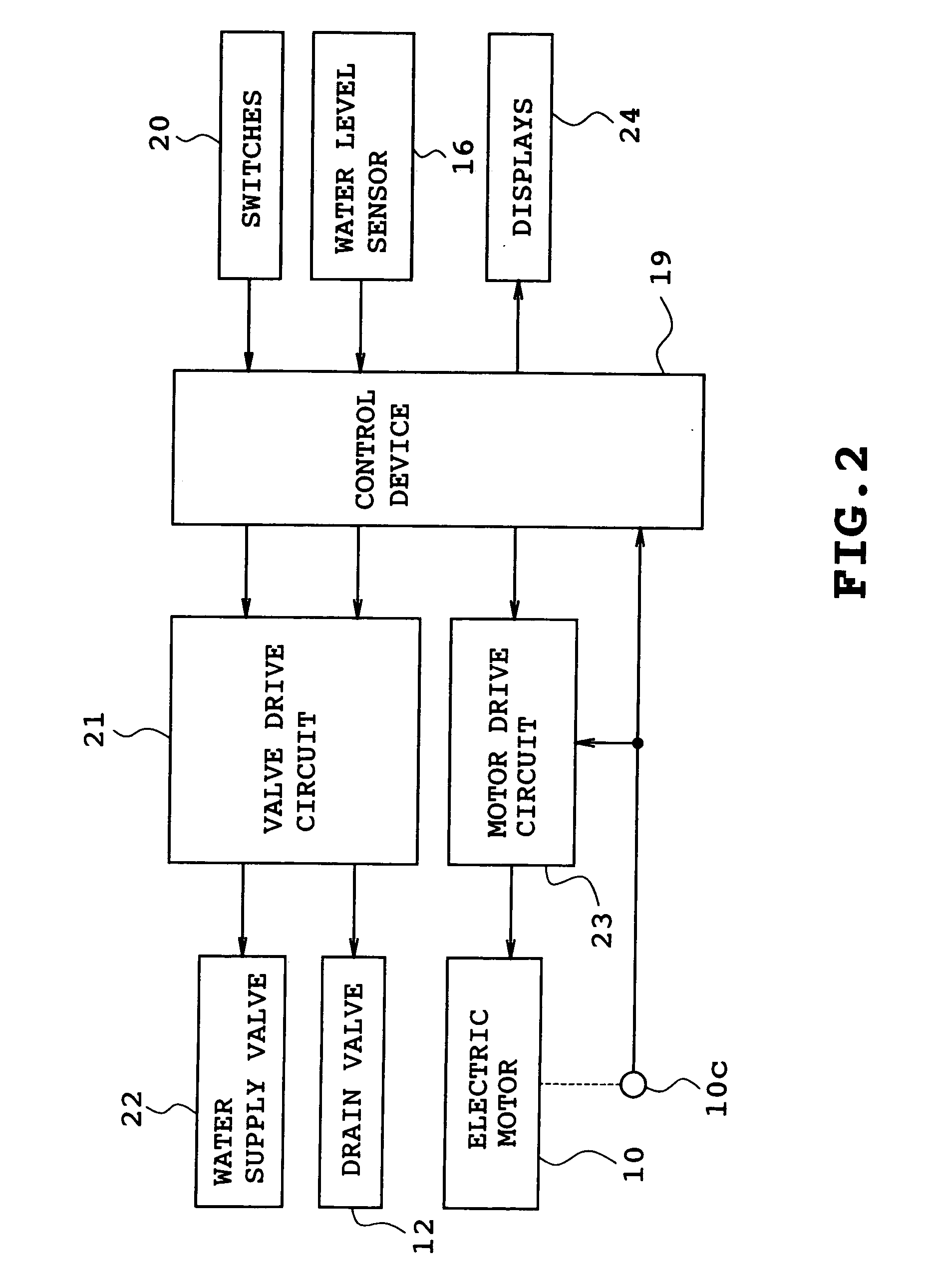

[0027]FIG. 1 is a longitudinal section of the overall washing machine comprising a rotating tub serving as a wash tub and a dehydration tub and directly driven by an inverter-controlled brushless motor. A washing machine body 1 in FIG. 1 roughly comprises a rectangular box-shaped outer cabinet 2 and a top cover 3 provided on the top of the outer cabinet 2. An outer tub or water-receiving tub 4 receiving dehydrated water is elastically supported by an elastic suspension mechanism 5 in the outer cabinet 2. A rotating tub 6 serving as a wash tub and a dehydration tub is rotatably provided in the water-receiving tub 4. The rotating tub 6 has a circumferential wall formed with a number of dehydration holes 6a. Water dehydrated from clothes is discharged through the dehydration holes 6a into the water-receiving tub 4 in the dehydration. Further, a balancing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com