Cooling air inlet arrangement

a technology of cooling air and inlet arrangement, which is applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of allowing noise to leave the compressor housing, and achieve the effect of reducing the amount of noise emitted by the machine and reducing the nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

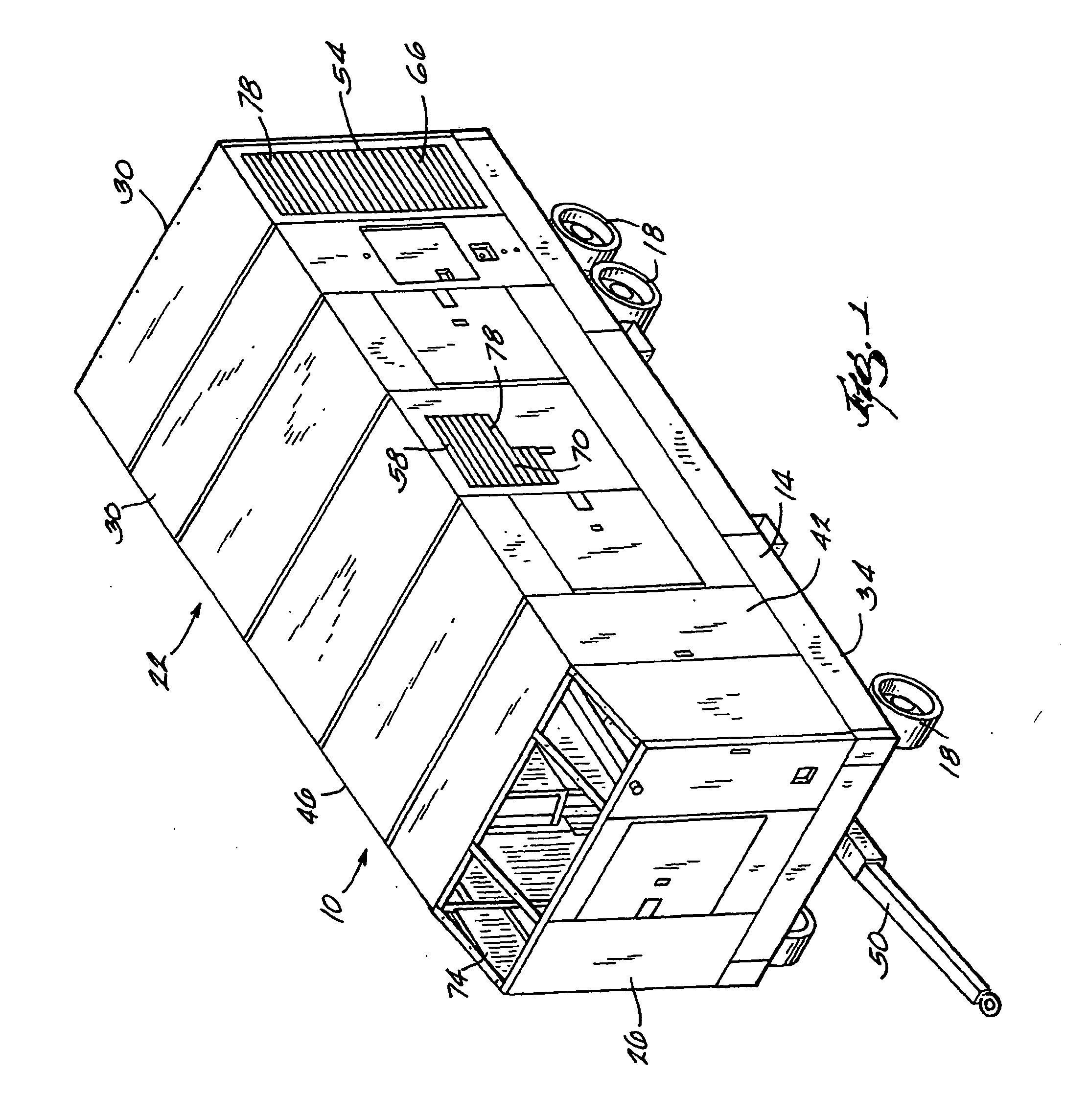

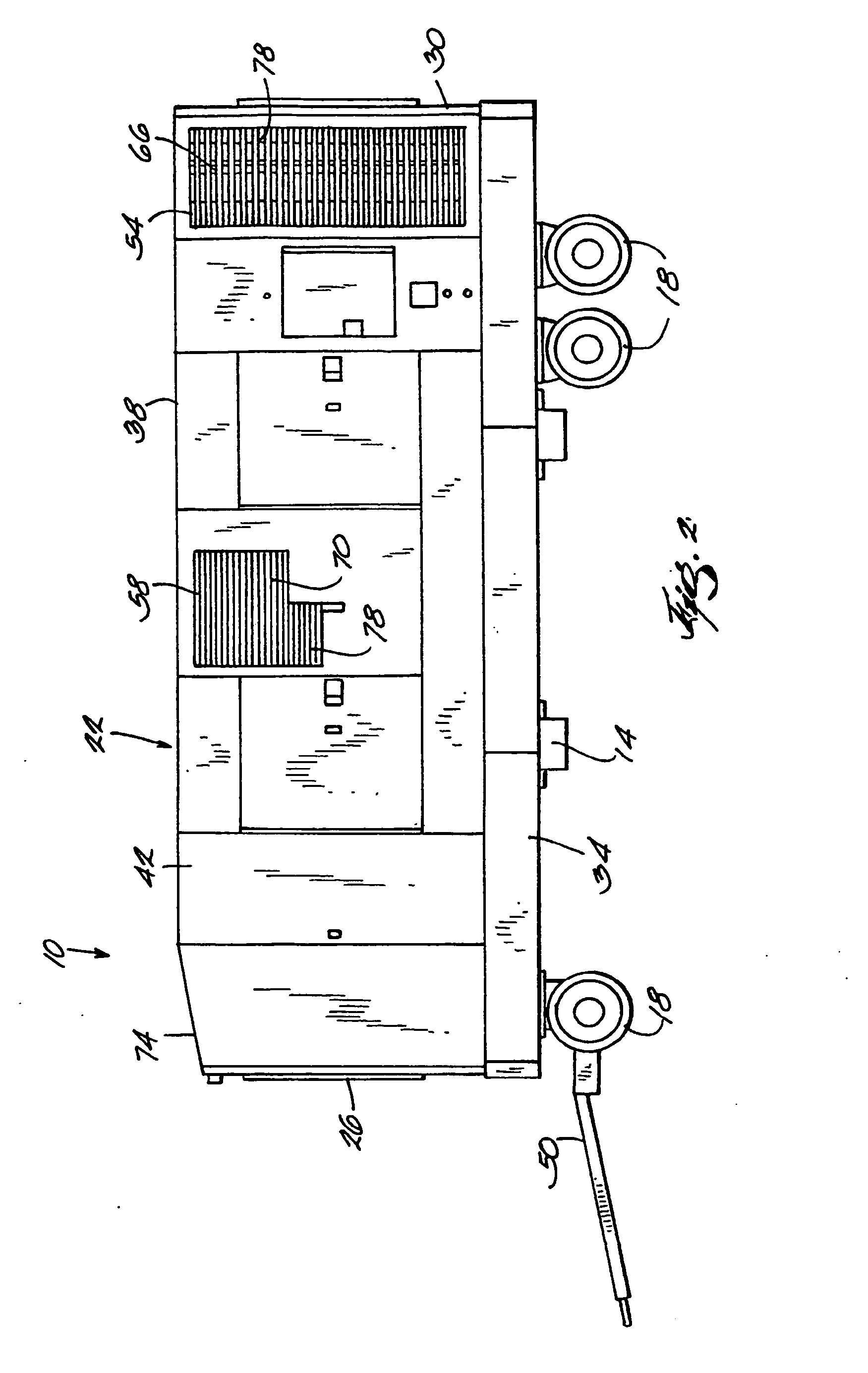

[0014]FIG. 1 illustrates a portable air compressor unit 10 that compresses air to pressures above normal atmospheric pressures. The compressor unit 10 includes a frame 14, wheels 18 supporting the frame 14, and a housing 22 supported by the frame 14. The housing 22 has a front end 26 and a rear end 30 disposed at opposite ends of the housing 22. The housing 22 includes a base 34, a roof 38, a left portion 42, and a right portion 46 that extend between the front end 26 and the rear end 30. The compressor unit 10 also has a tongue 50 that may interconnect to a vehicle and facilitate transporting the portable air compressor unit 10.

[0015] The frame 14 supports the housing 22 and the internal components of the air compressor unit 10 disposed within the housing 22. In the illustrated embodiment, the housing 22 is a substantially rectangular box, but the housing may be any shape that substantially encloses the components of the compressor unit 10. The internal components of the air compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com