Multi-stranded coil spring

a coil spring and multi-strand technology, applied in the field of spring construction, can solve the problems of high cost of steel suitable for this type of spring, impaired seating and/or sleeping comfort of seating or resting surface, etc., and achieve the effect of lessening the adverse effects caused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

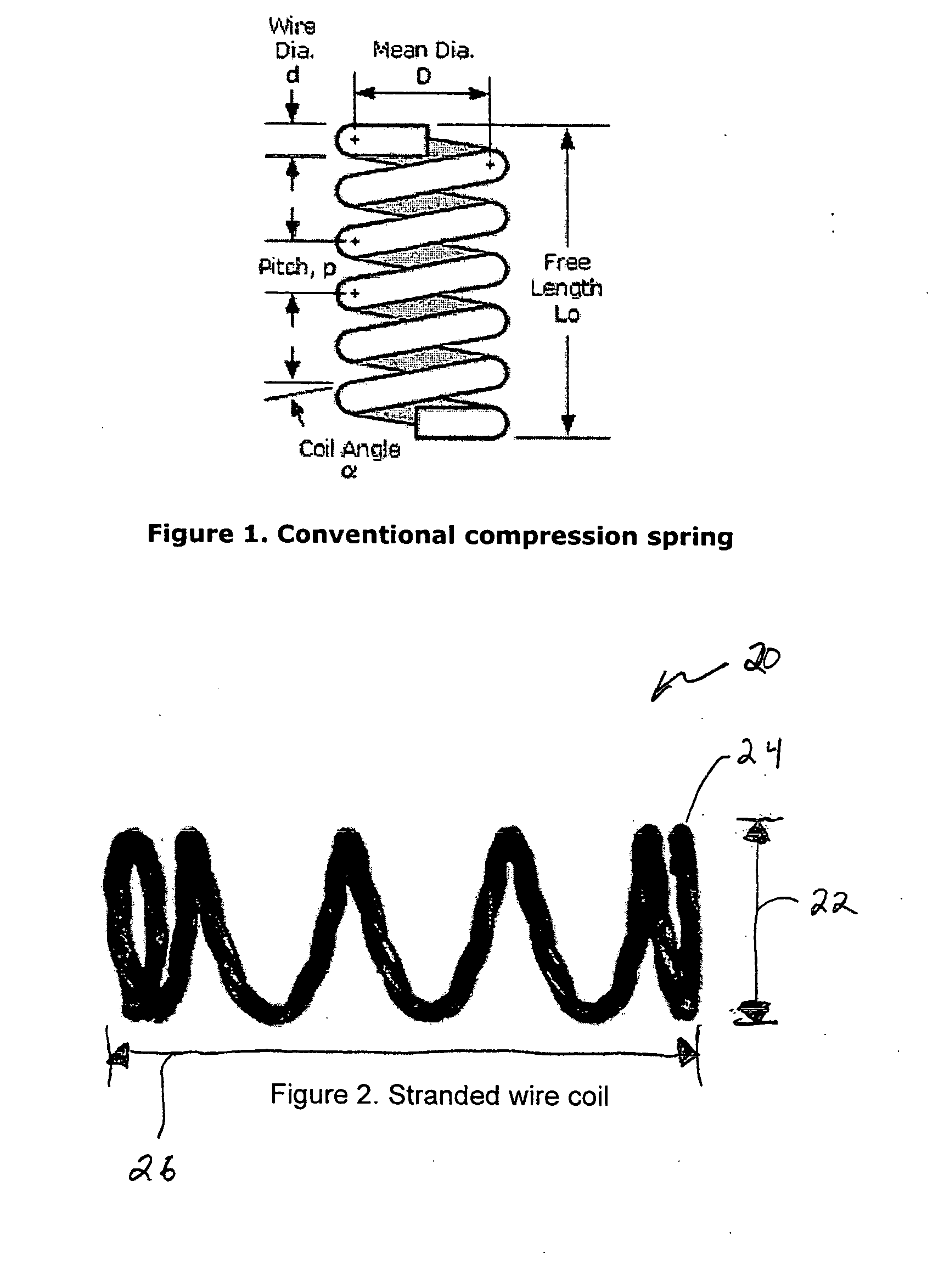

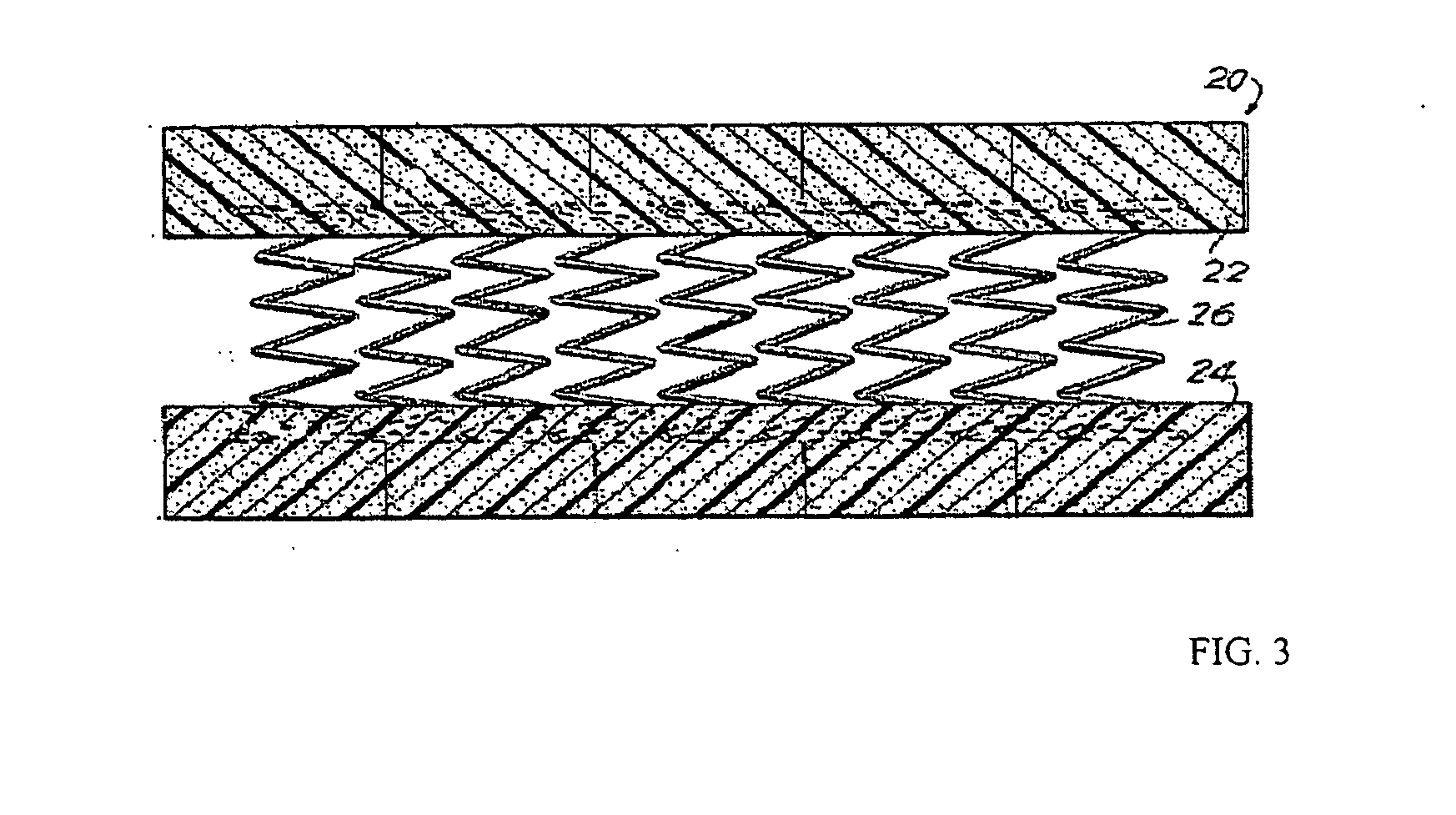

[0027] The multi-strand coil springs described herein can be used, for example, to construct a wide variety of coiled spring applications, including seating and resting surfaces of articles of furniture. In particular, the multi-strand coil construction can be a more versatile replacement for single strand or solid coils in mattresses, providing enhanced utility and performance. For purpose of illustration, the coils described herein will be described with reference to pocketed coil mattresses. However, the invention is not so limited, and may be employed with other coil spring applications including, but not limited to, seating, flooring, weaponry, writing instruments, spring hinge designs, spring locking mechanisms, spring wound motors, specialized medical applications, industrial tools, spring brake devices, resilient shock absorption applications and the like.

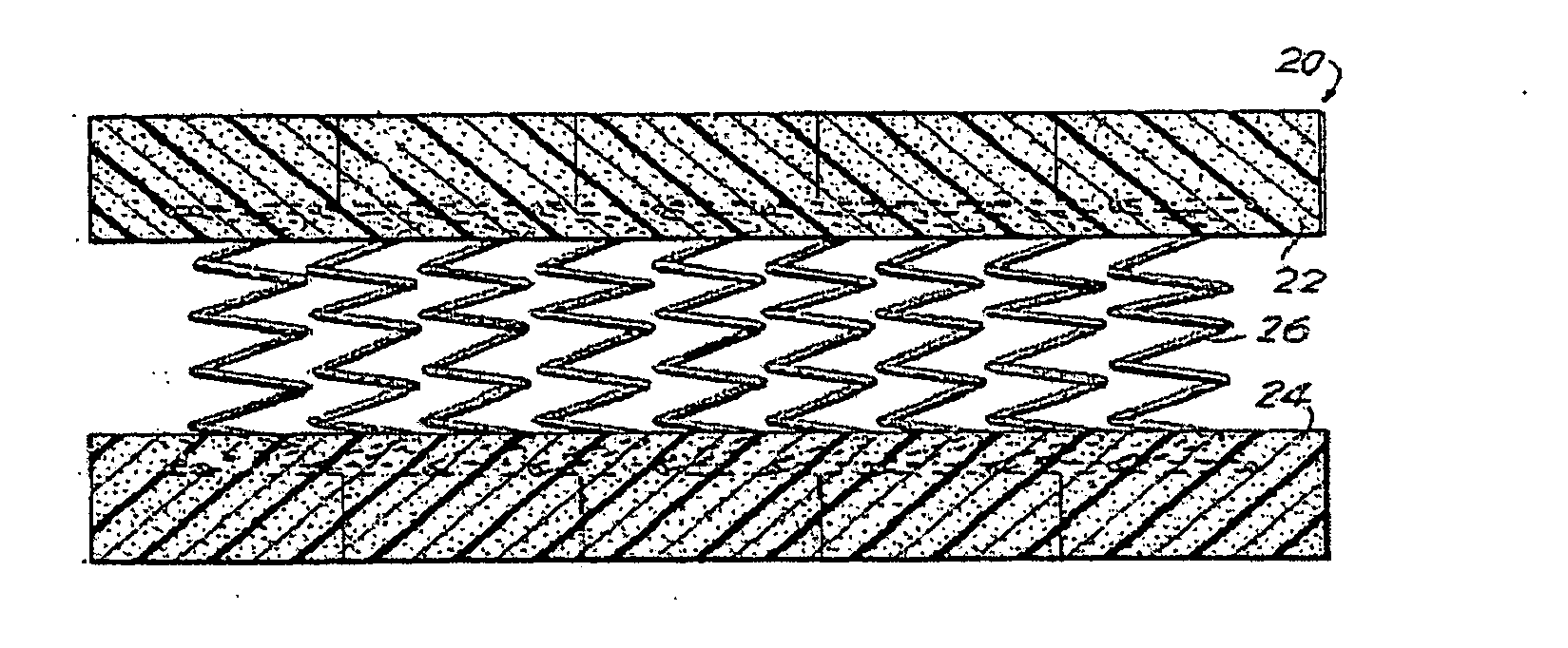

[0028]FIG. 1 illustrates the basic geometric parameters defining a helical compression spring. The primary spring geomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com