Conveyor belt cleaning system

a conveyor belt and cleaning technology, applied in the direction of cleaning, conveyor parts, transportation and packaging, etc., can solve the problems of reducing the contacting force of the belt, and reducing the cleaning efficiency of the scraper blade assembly,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

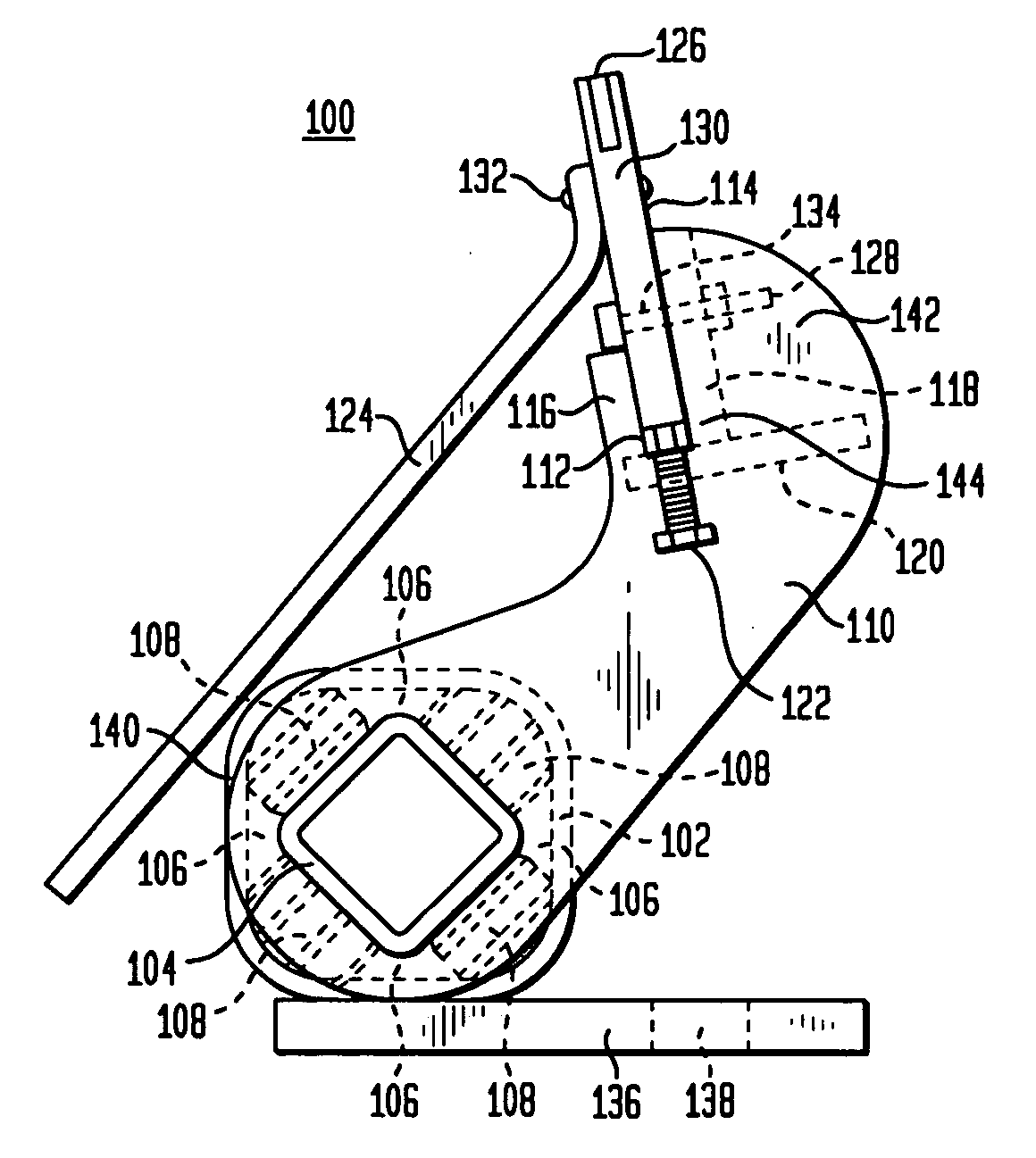

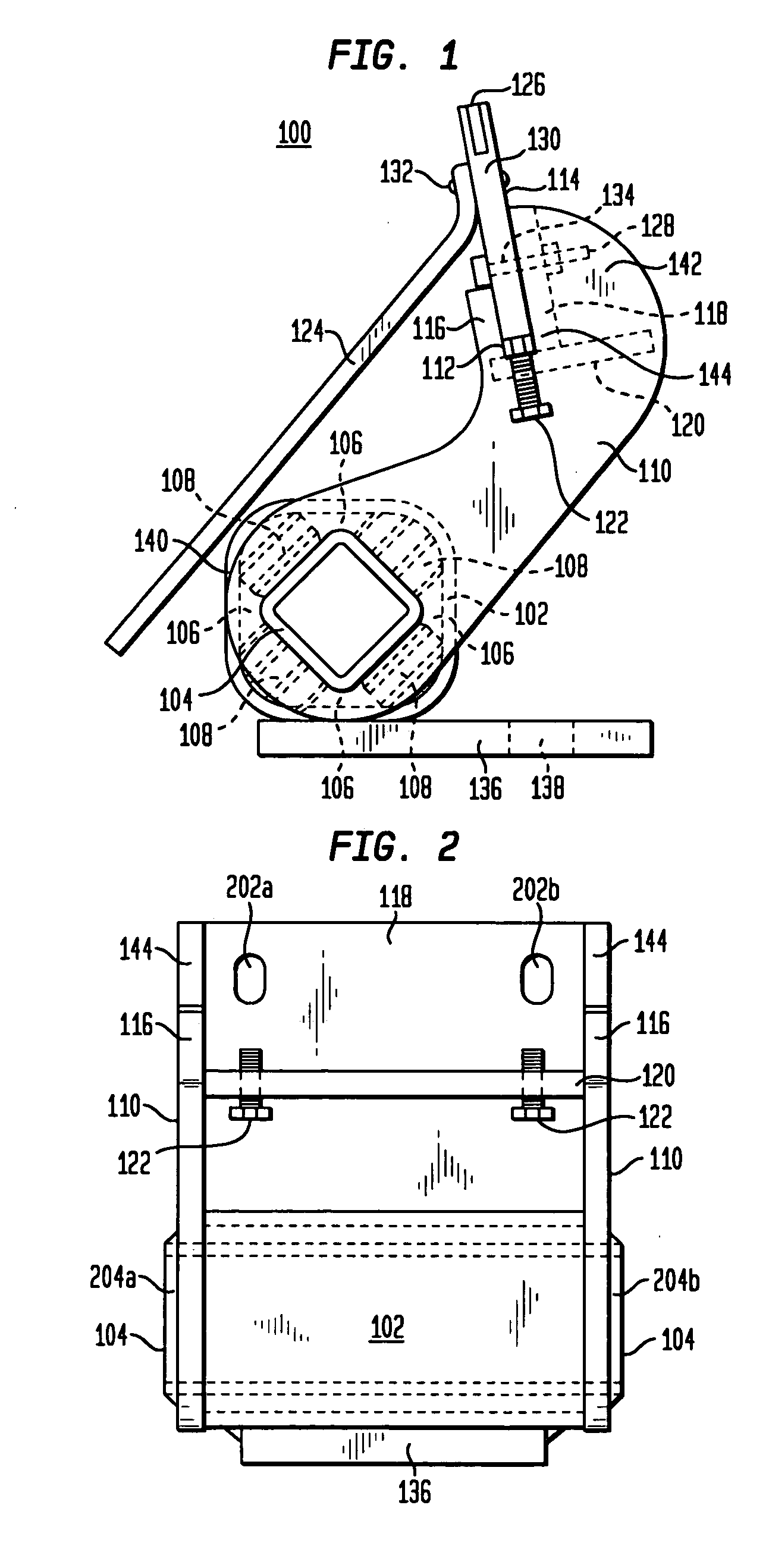

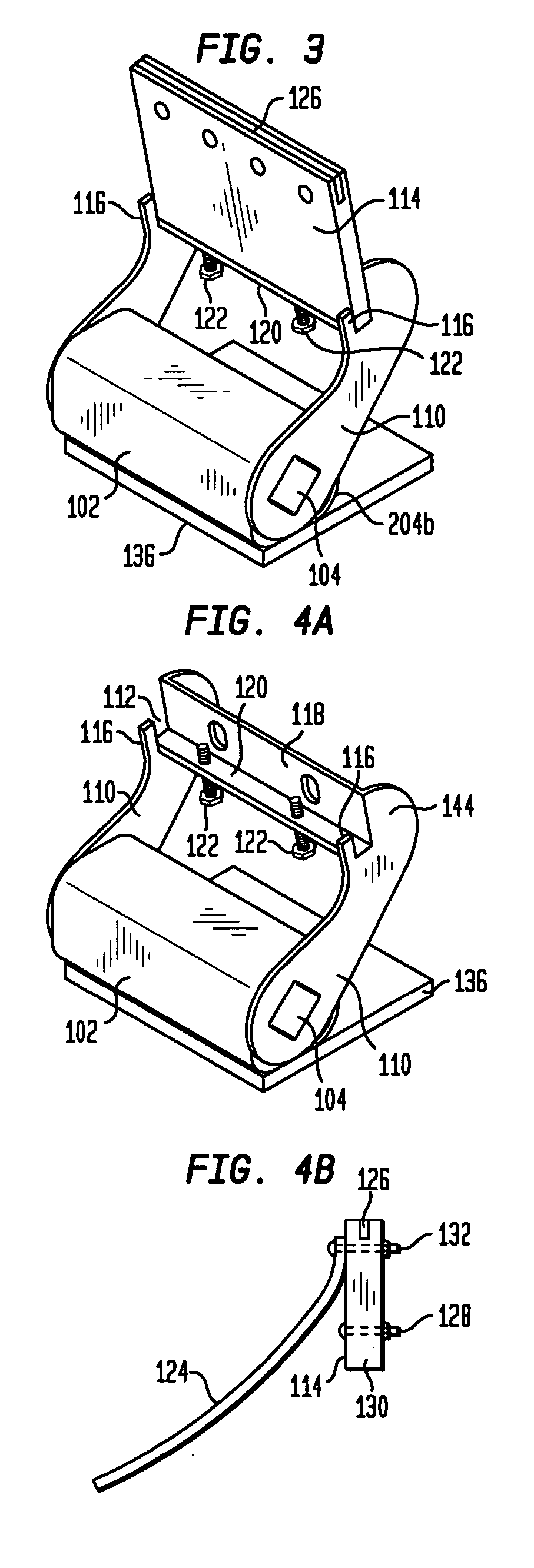

[0035] FIGS. 1-4B show an exemplary embodiment of the torsion blade holder assembly 100 of the present invention, FIGS. 5A-D show an alternative embodiment adapted for use with a means for spraying a liquid on a conveyor belt either prior to or after scraping, and FIGS. 6-8 illustrate various alternative embodiments of the present invention. The torsion blade holder assembly 100 of the present invention comprises two sub-assemblies: a mounting sub-assembly and a blade support sub-assembly, wherein the blade support sub-assembly is connected to the mounting sub-assembly and the mounting sub-assembly secures the blade support assembly (and thereby secures the torsion blade holder assembly 100) to a shaft such that a surface of a conveyor belt travels over and in contact with a scraper blade 114 within the blade support sub-assembly as a means for cleaning the surface of the conveyor belt.

[0036] In the preferred embodiment, the mounting sub-assembly employs torsion means for allowing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com