Method and device for the production of tubular knitted articles and in particular for closing the toe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

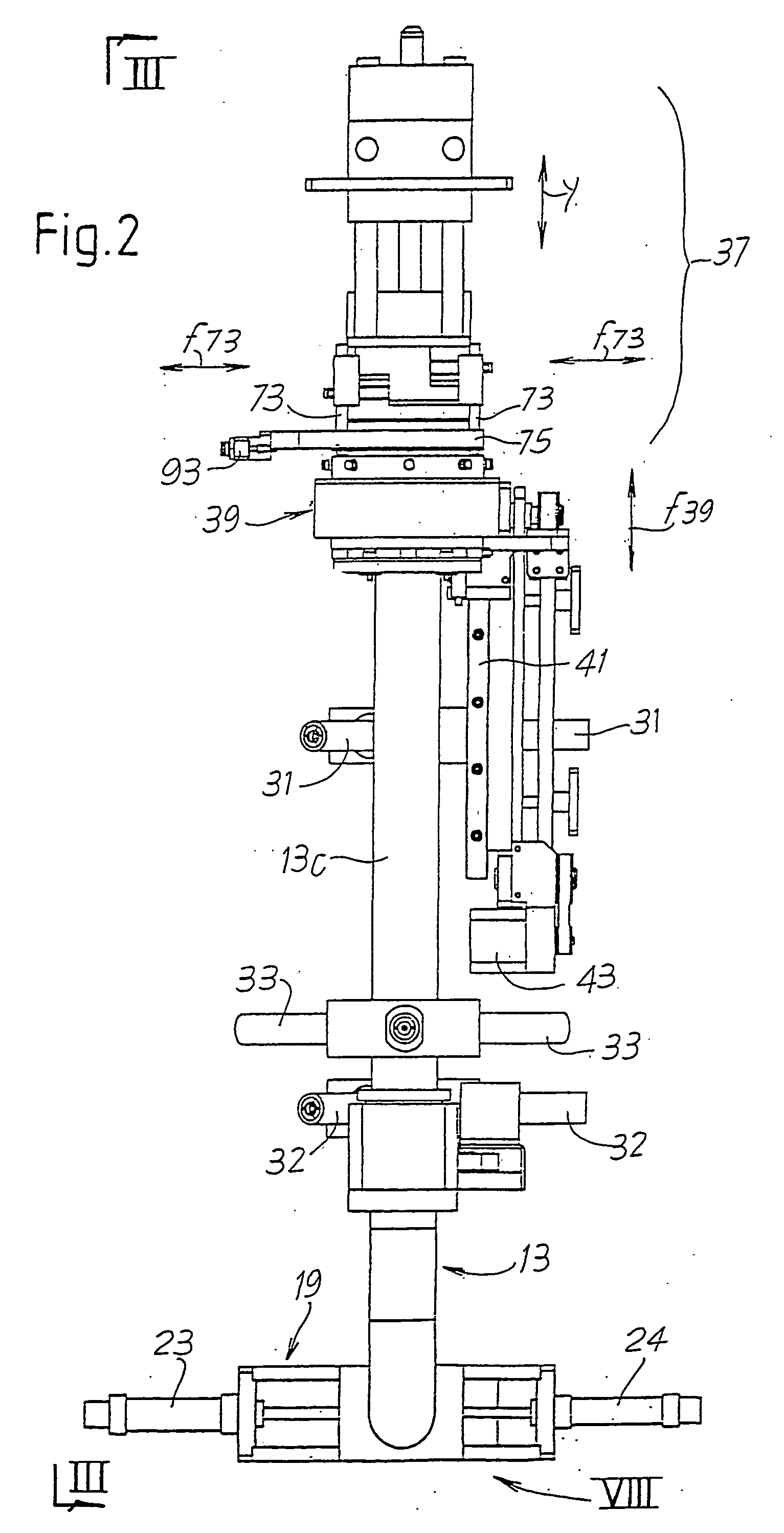

[0080] The devices for picking up and sewing tubular articles are shown in FIG. 4 in combination with a circular knitting machine, and in isolation from the knitting machine in FIGS. 1 to 3. The internal structure of the pick-up device may be seen in FIGS. 17 to 28. In some of the figures, parts of the devices have been removed for greater clarity of representation. In what follows generic reference will frequently be made to the ensemble made up of the pick-up device and sewing device as to a single device for picking up the article and closing the toe, it being, however, understood that the pick-up device may be combined with a different device for closing the toe and vice versa.

[0081] In the attached drawings, the device for picking up the tubular article and closing the toe is designated, as a whole, by 1, whilst 3 designates, as a whole, the circular knitting machine that produces the tubular article. Of the circular knitting machine 3, only the essential components are indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com