Modular lance

a module and lance technology, applied in the direction of manufacturing converters, charge manipulation, furnaces, etc., can solve the problems of reducing the likelihood that the internal pipes will be stressed beyond the tensile limit, failure in operation, and inability to carry out routine transportation of the spent lances, so as to achieve less maintenance and repair, the effect of quick and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

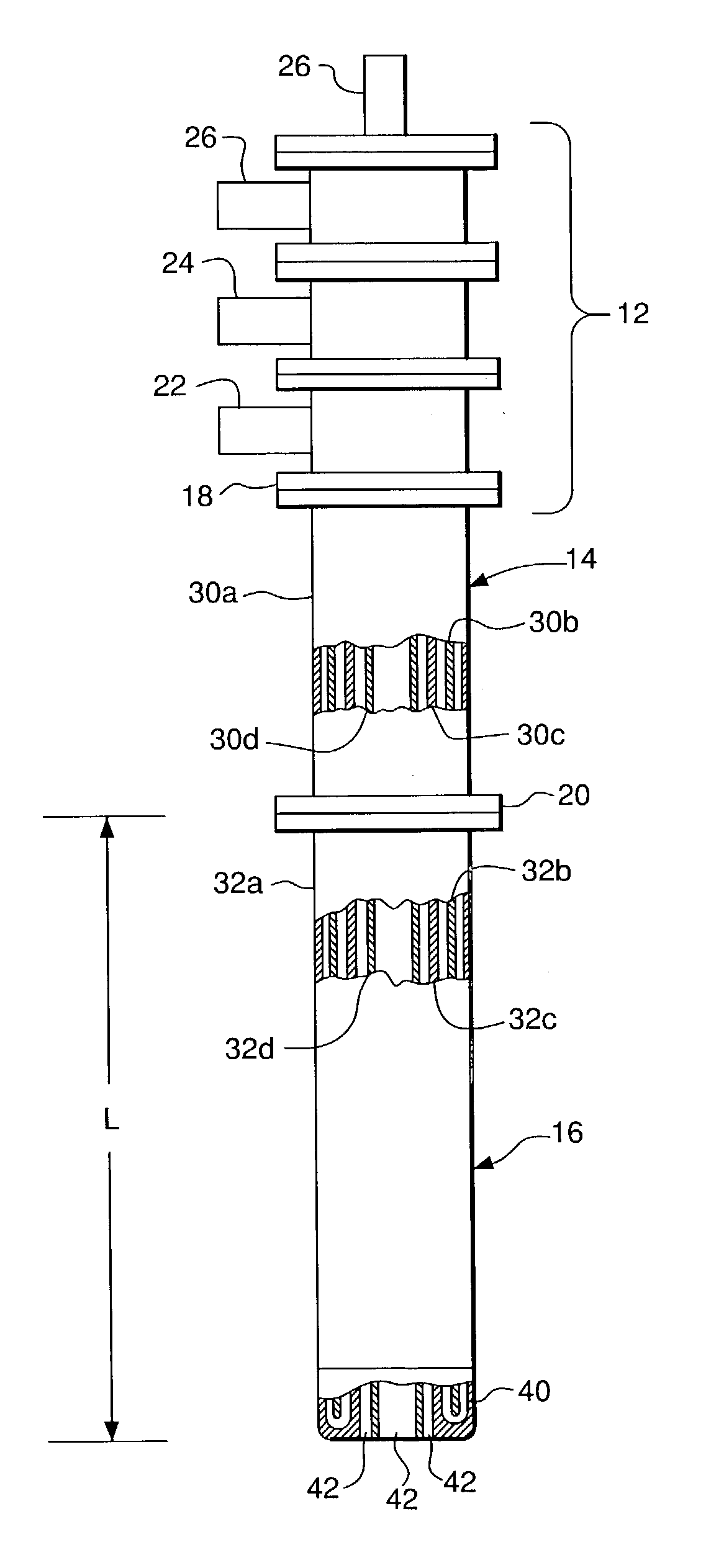

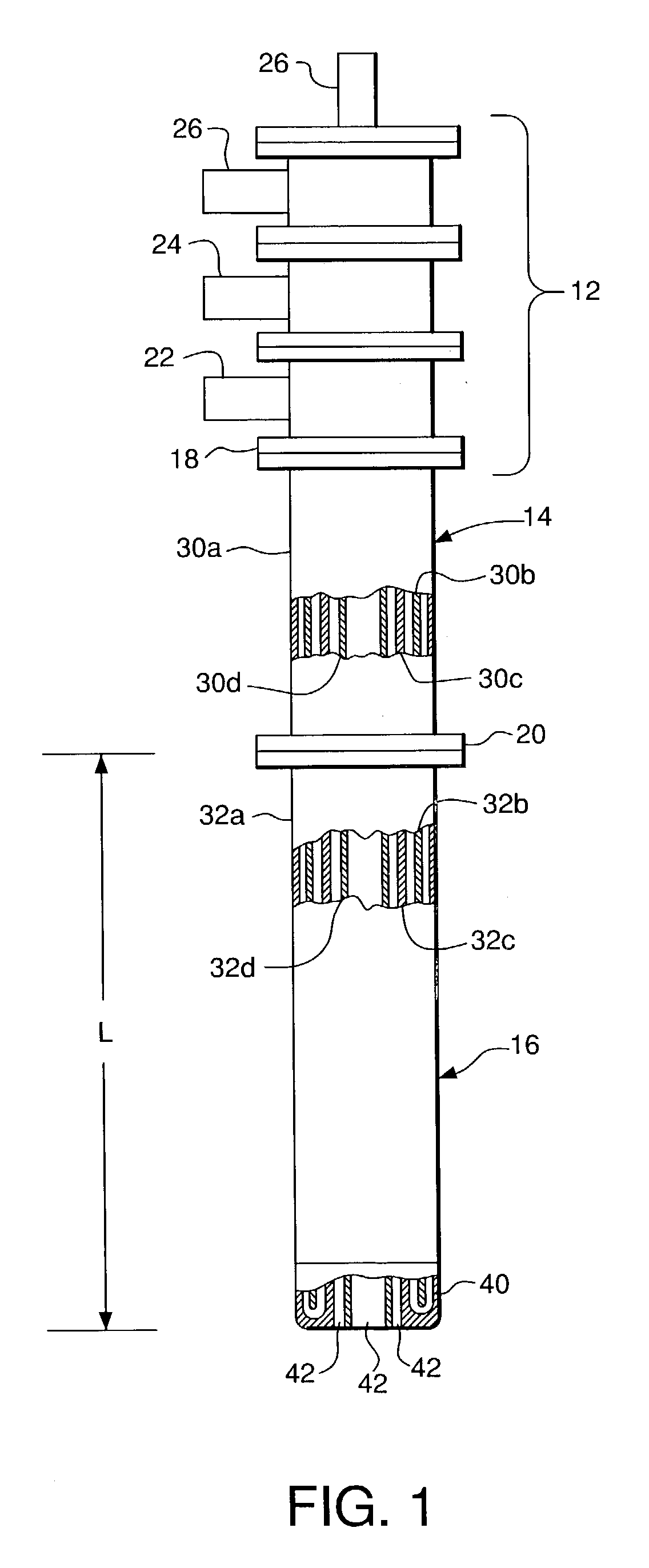

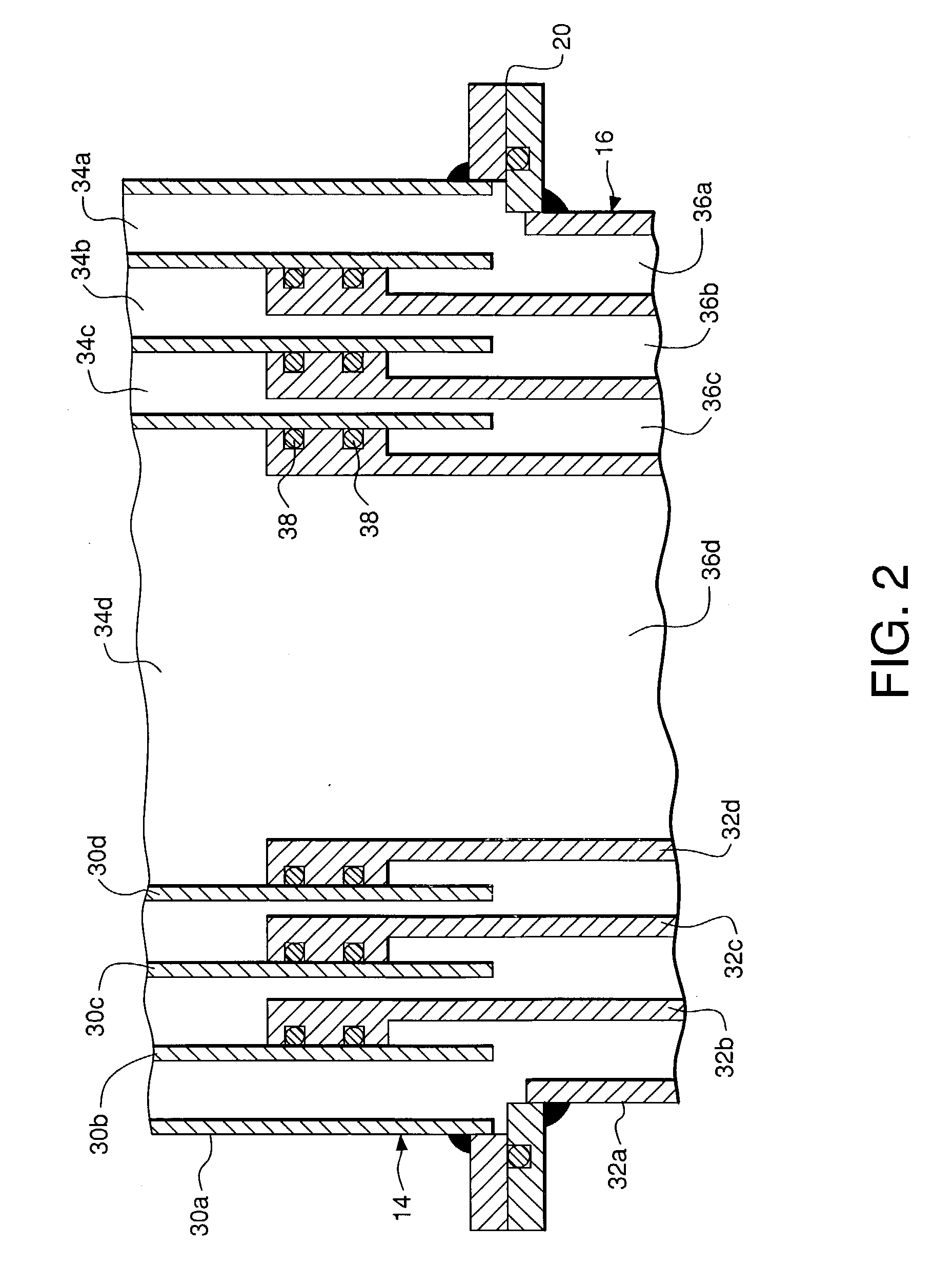

[0022] Referring to FIG. 1 there is shown a modular lance according to the present invention identified generally by reference numeral 10. Lance 10 preferably comprises a top adapter 12, an upper section 14 and a plug-in lower section 16 that may be respectively joined to one another at flanged joints 18 and 20 by any conventional metal fusion joining processes such as brazing, welding or the like, or by screws, bolts, clips, clamps or other mechanical joining arrangements.

[0023] As is conventional, top adapter 12 preferably comprises a segmented housing having at least one refining agent inlet that delivers one or more gaseous, liquid and / or solid refining agents to the top adapter from at least one unillustrated source of such agents. Depending on the intended use of lance 10, top adapter 12 may be adapted to convey only one or more refining agents. However, when configured as a cooled lance (as illustrated), the top adapter may comprise a coolant water outlet 22, a coolant water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com