Container with stackable base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

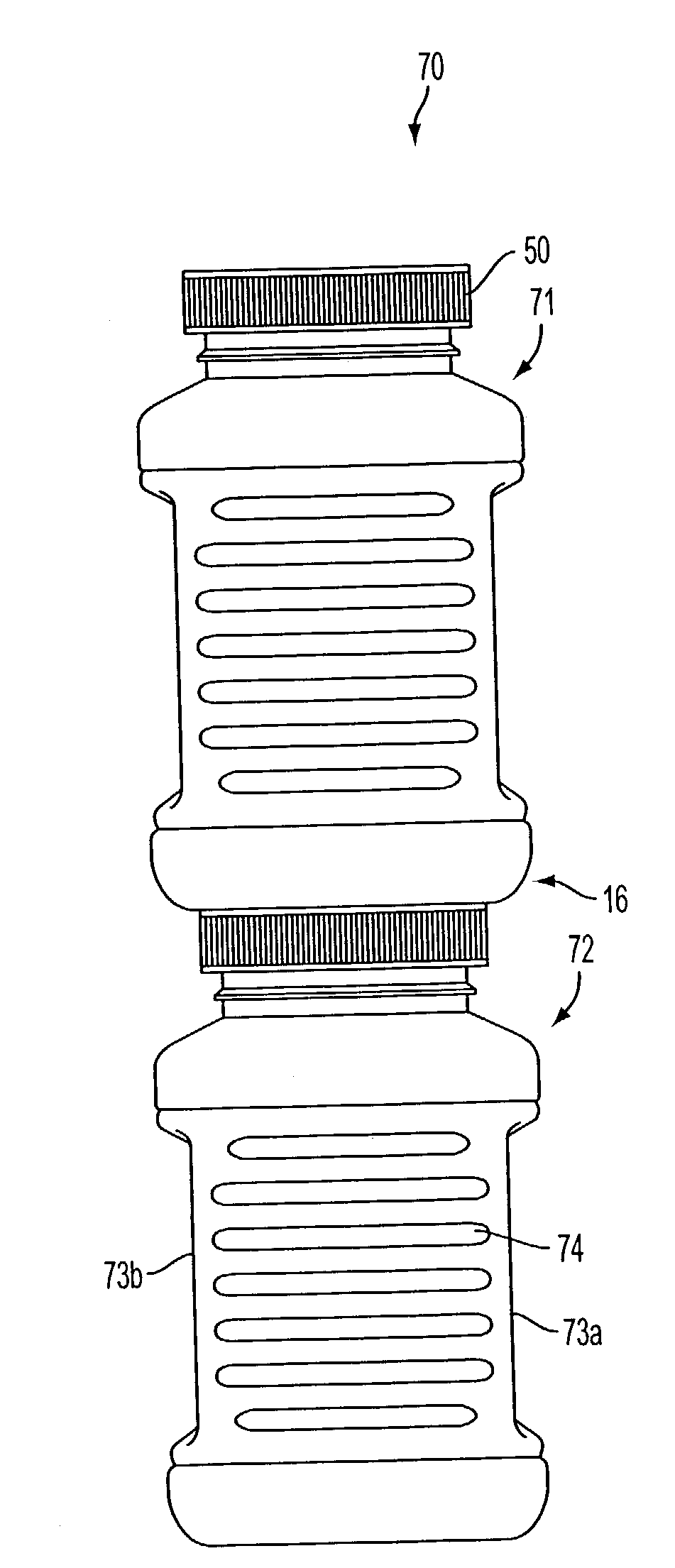

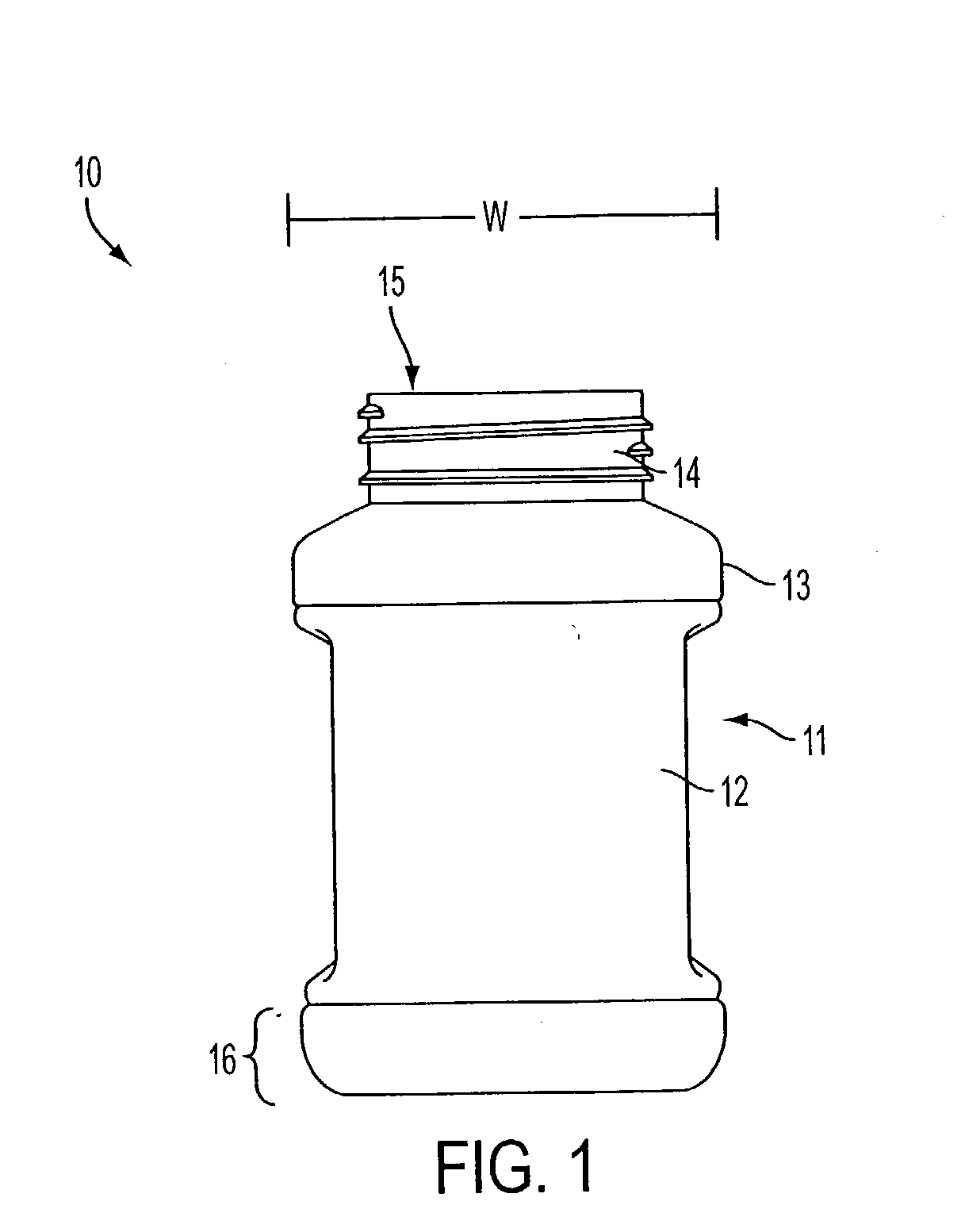

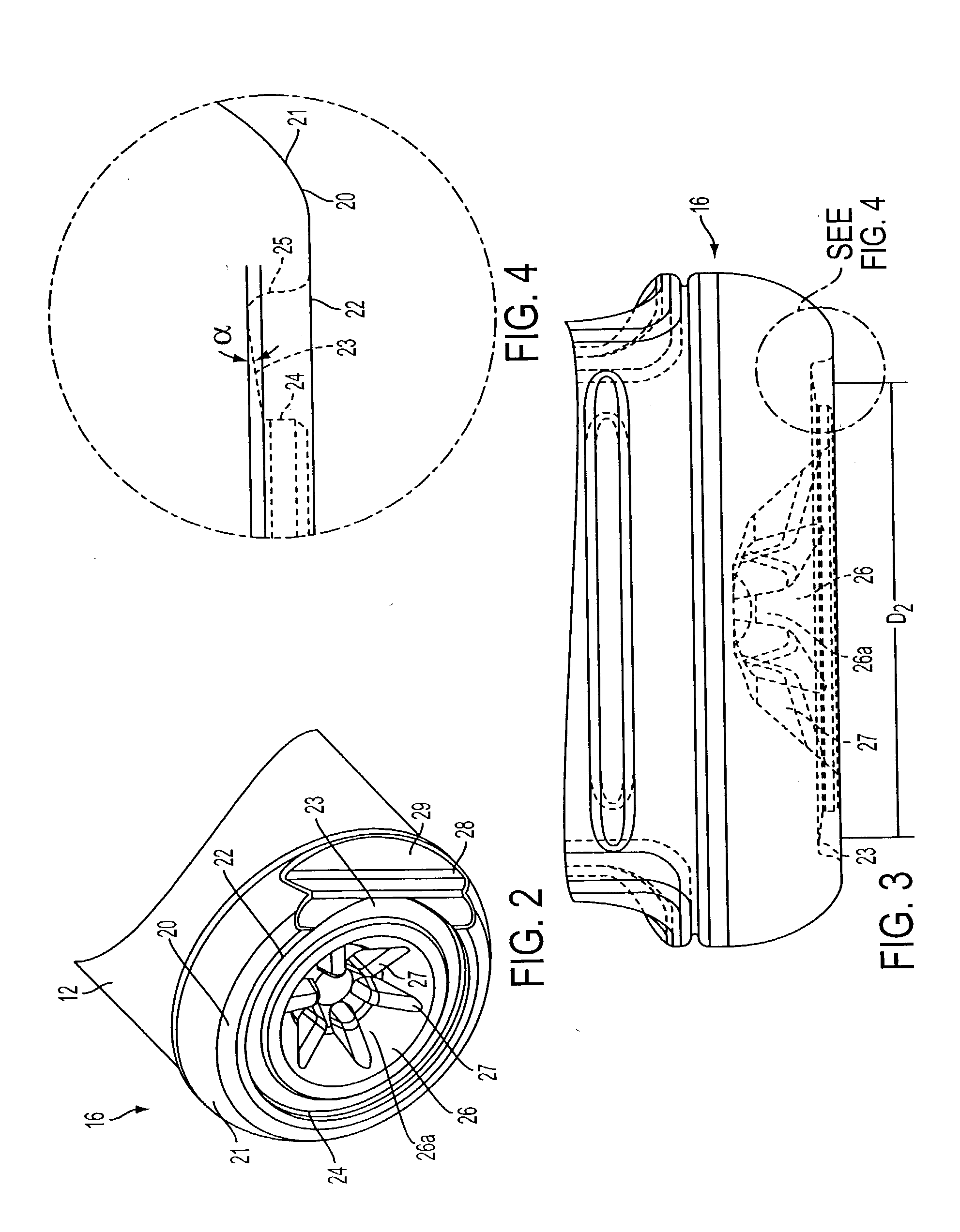

[0048] The significantly improved resistance to tilting of a stack of containers according to the present invention was demonstrated in the following tests conducted on containers, which were bottles fitted with two piece screw caps. The containers were equivalent except that the "control containers" did not have a base according to the present invention defined in their bottoms. The "stackable containers" according to the invention had bases as illustrated in FIGS. 2-5 and 6A.

[0049] A two-piece 63 mm ribbed closure was employed which included a plastic ring having a peripheral rim with a raised annular section with a 65.9 mm outer diameter and a 54 mm inner diameter, and a metal disk positioned within and retained by the ring. The raised annular section had a radial cross-sectional shape, which was generally rectangular and extended vertically above the plane of the metal disk by about 2 mm. The width of the longer leg of the rectangle was about 6 mm. Containers according to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com