Aircraft fluid drip pan system

a drip pan and fluid technology, applied in the field of aircraft fluid drip pan system, can solve the problems of affecting the environment, affecting the parking surface, and affecting the operation of aircraft, and achieve the effect of effectively fixing the drip pan, preventing the movement of the pan by wind, and effective positioning of the drip pan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

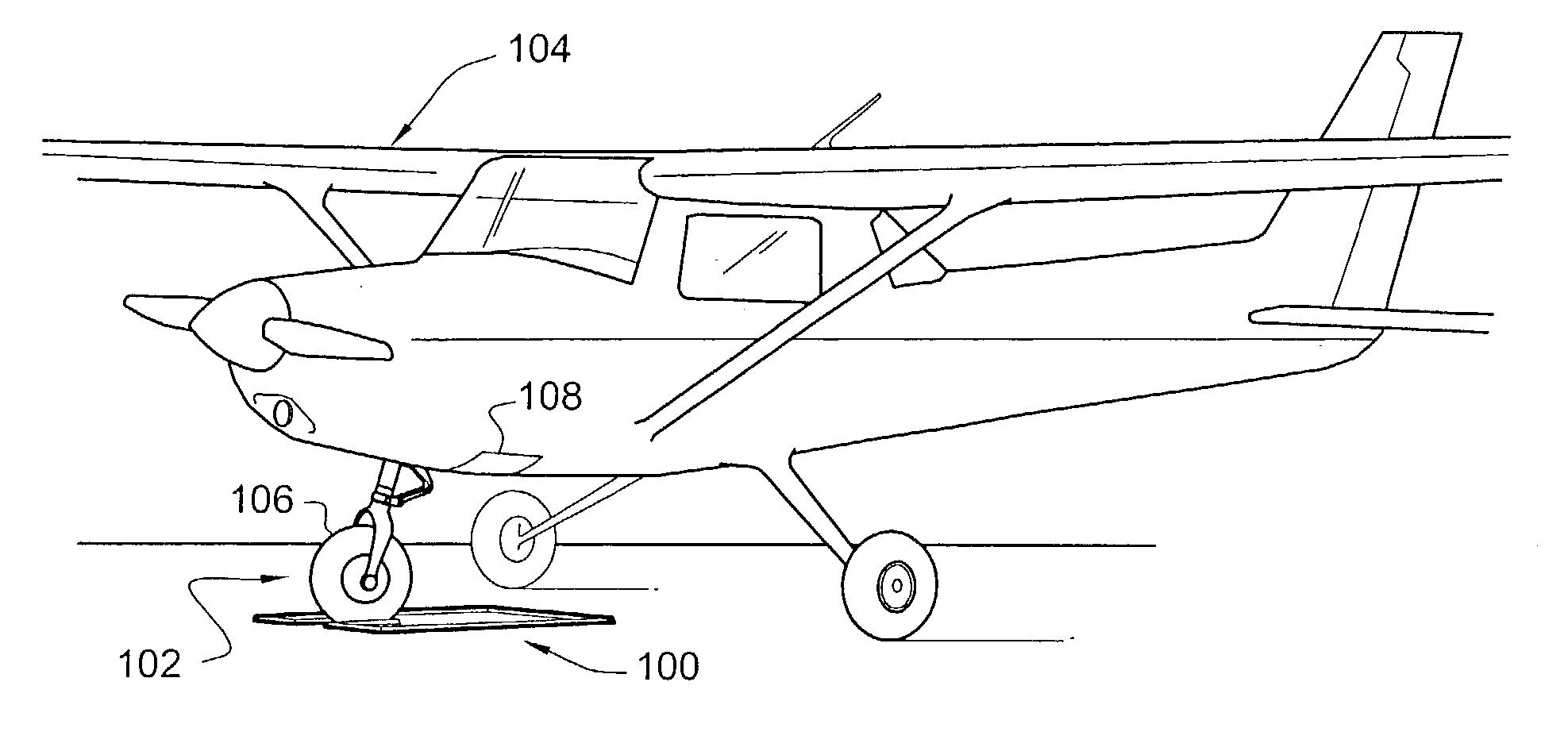

[0034] Reference is now made to the drawings. FIG. 1 is a perspective view of drip pan system 100 positioned around the front wheel area 102 of aircraft 104 according to a preferred embodiment of the present invention. Because the engine compartments of light aircraft are typically located above the nose wheel 106 of single engine aircraft, as shown, and commonly adjacent to the main landing gear wheels of twin-engine aircraft, conventional drip pans intended for use by automobiles cannot be used, not having an accommodation for the wheel. Preferably, drip pan system 100 is adapted to permit effective positioning under the engine compartment 108 of aircraft 104 by incorporating peripheral wheel cutout 110, as shown in FIG. 2.

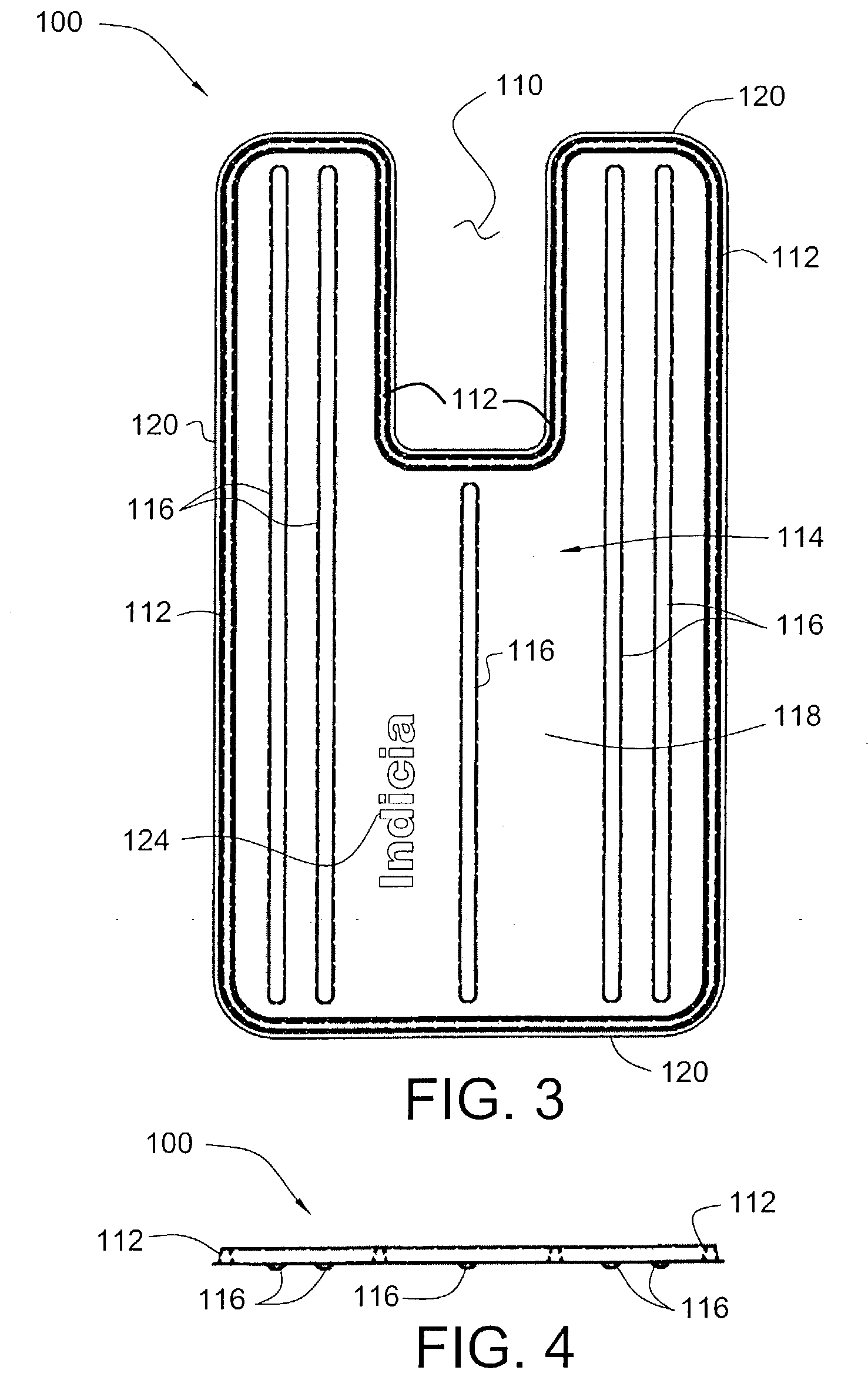

[0035] FIG. 2 is an isometric view of the drip pan system 100 (embodying herein fluid retaining means for retaining the fluids discharged from the aircraft; and also embodying herein at least one fluid retainer structured and arranged to retain the fluids discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com