Cortical bone-based composite implants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

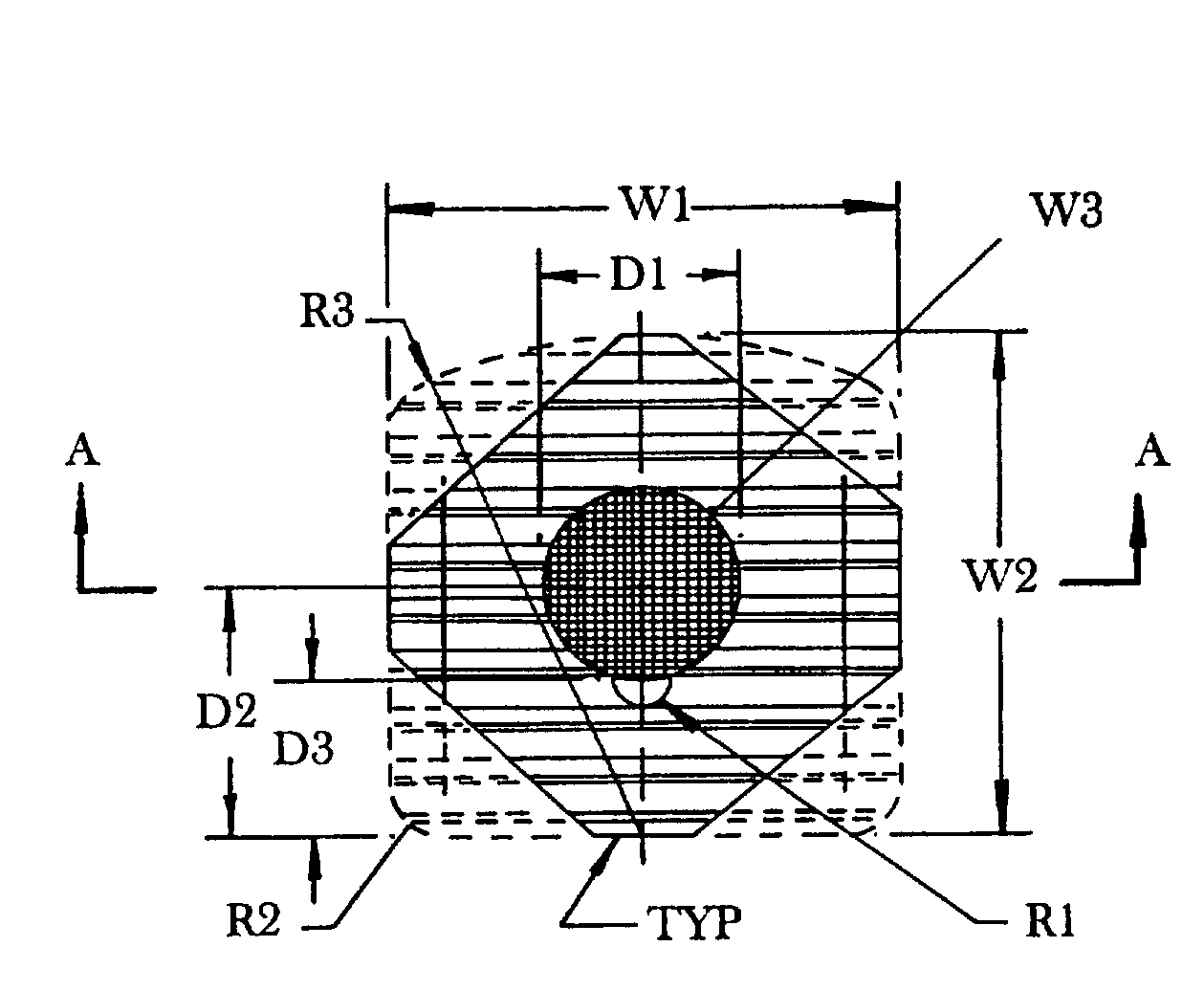

Method used

Image

Examples

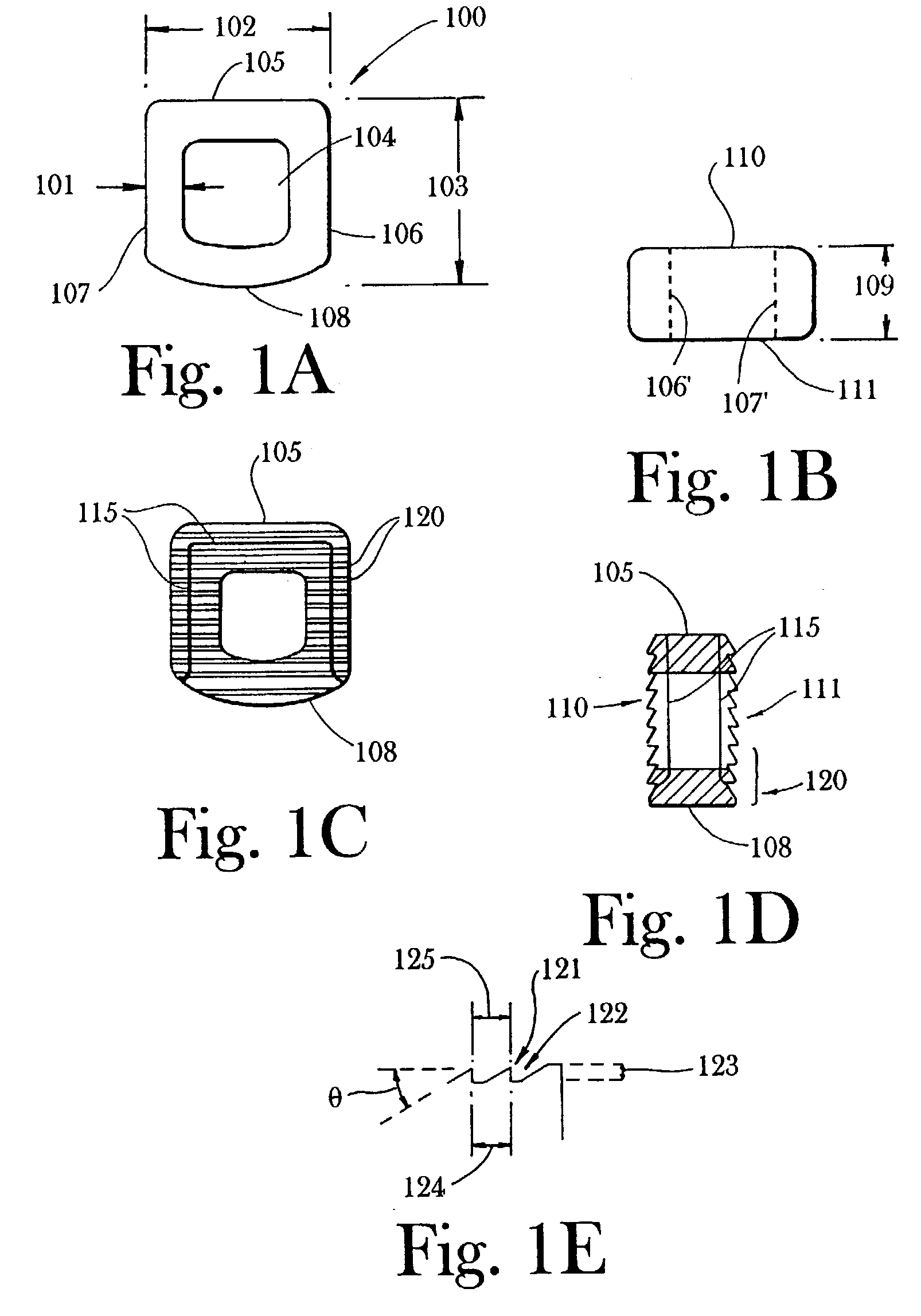

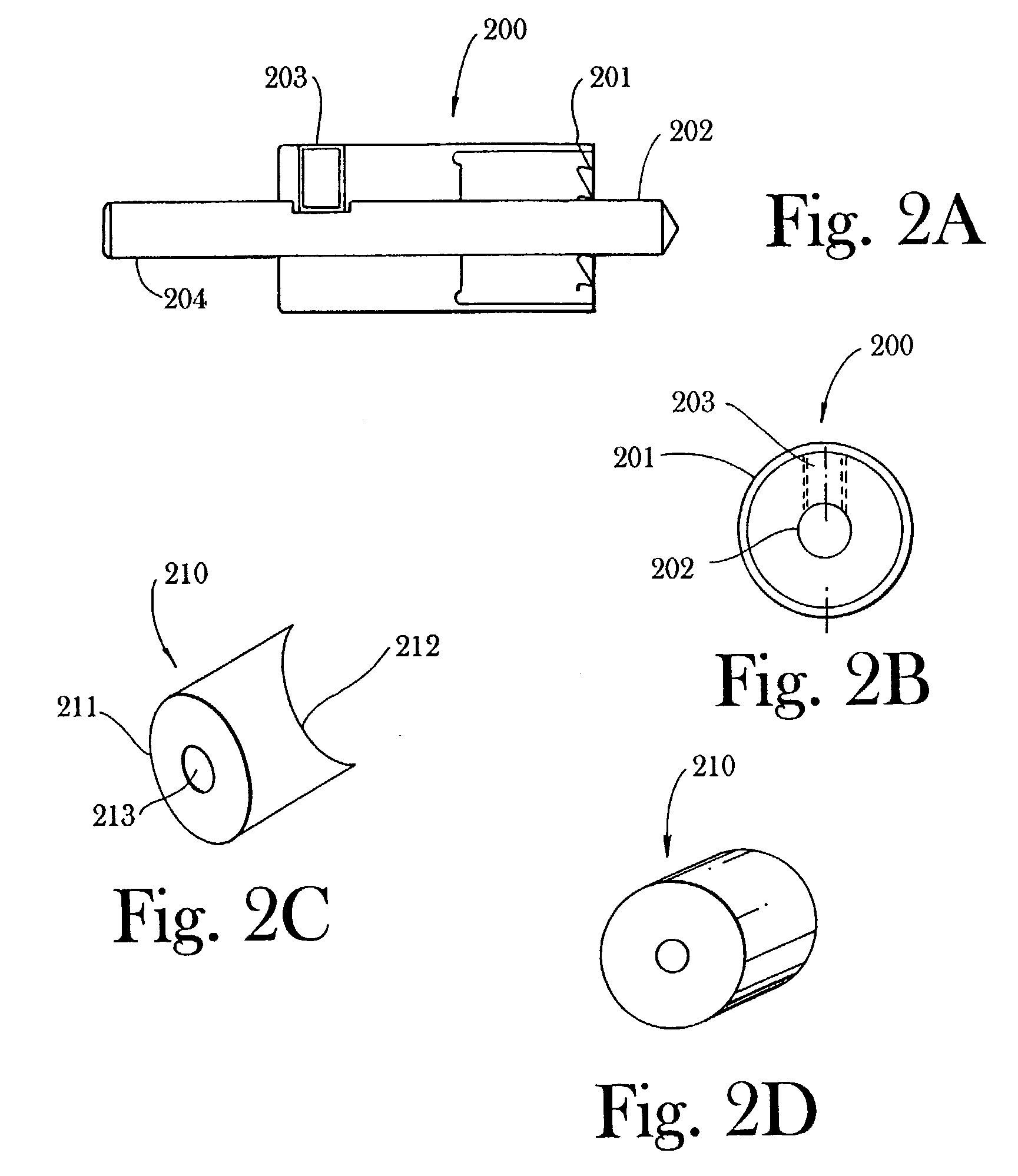

Embodiment Construction

[0022] According to this invention, a substantially "D"-shaped cortical bone implant for cervical Smith-Robinson fusions is produced, preferably under aseptic conditions. Class 10 clean room processing is desirable, and sterilization of all machining tools is likewise preferred, (particularly after switching from one allograft donor to the next), so that the finished product may be treated by standard techniques known in the art (alcohol, peroxide, or like treatments), prior to storage and shipment to physicians for use in implantation procedures. Because of the peculiarities of working with bone, and in particular, because of the desirability of maintaining aseptic conditions while working with this material, novel approaches have been adopted in the production of the product of this invention.

[0023] The implant is preferably formed from cortical bone obtained from tibia, femur or other source of strong cortical bone. The bone source may be autograft or, due to possible complicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com