Pressure vessel head ring assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

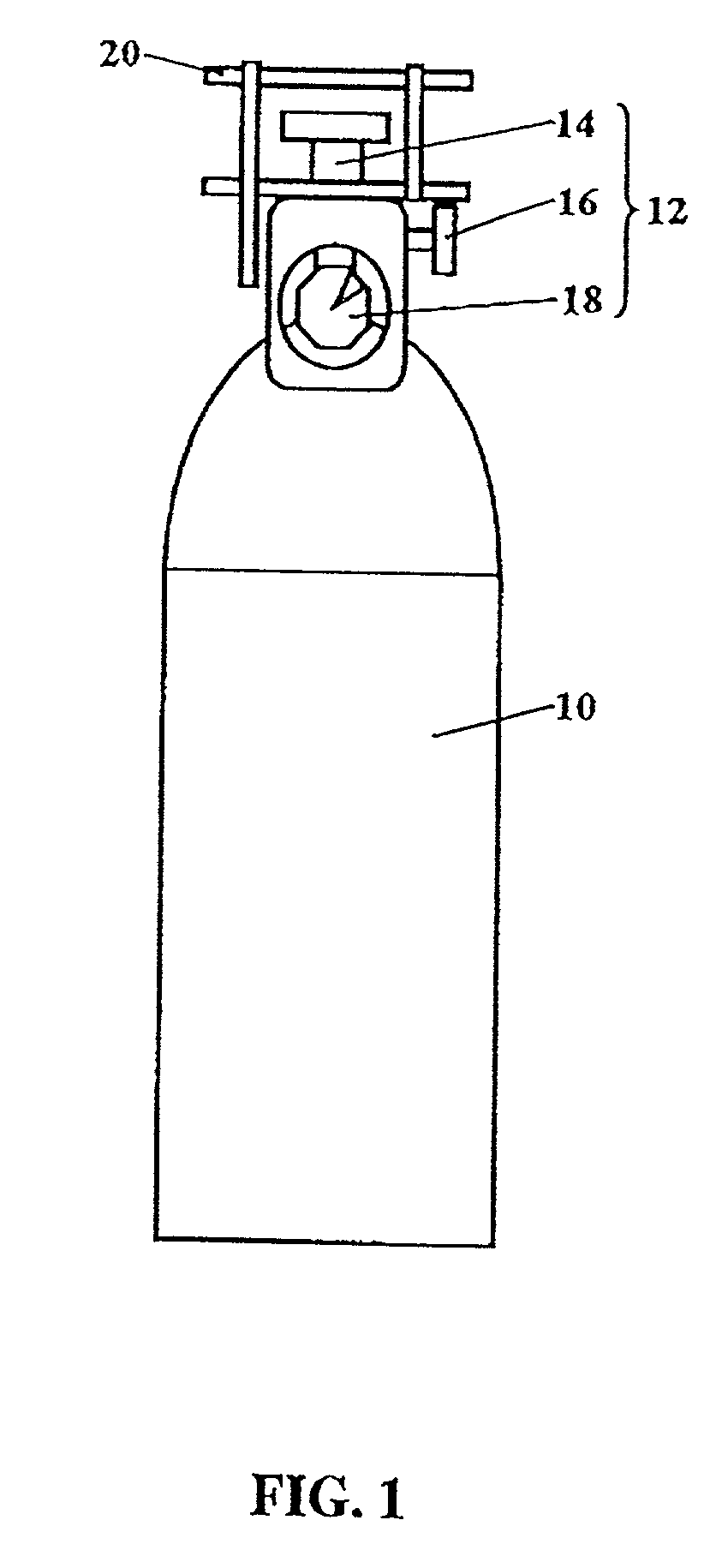

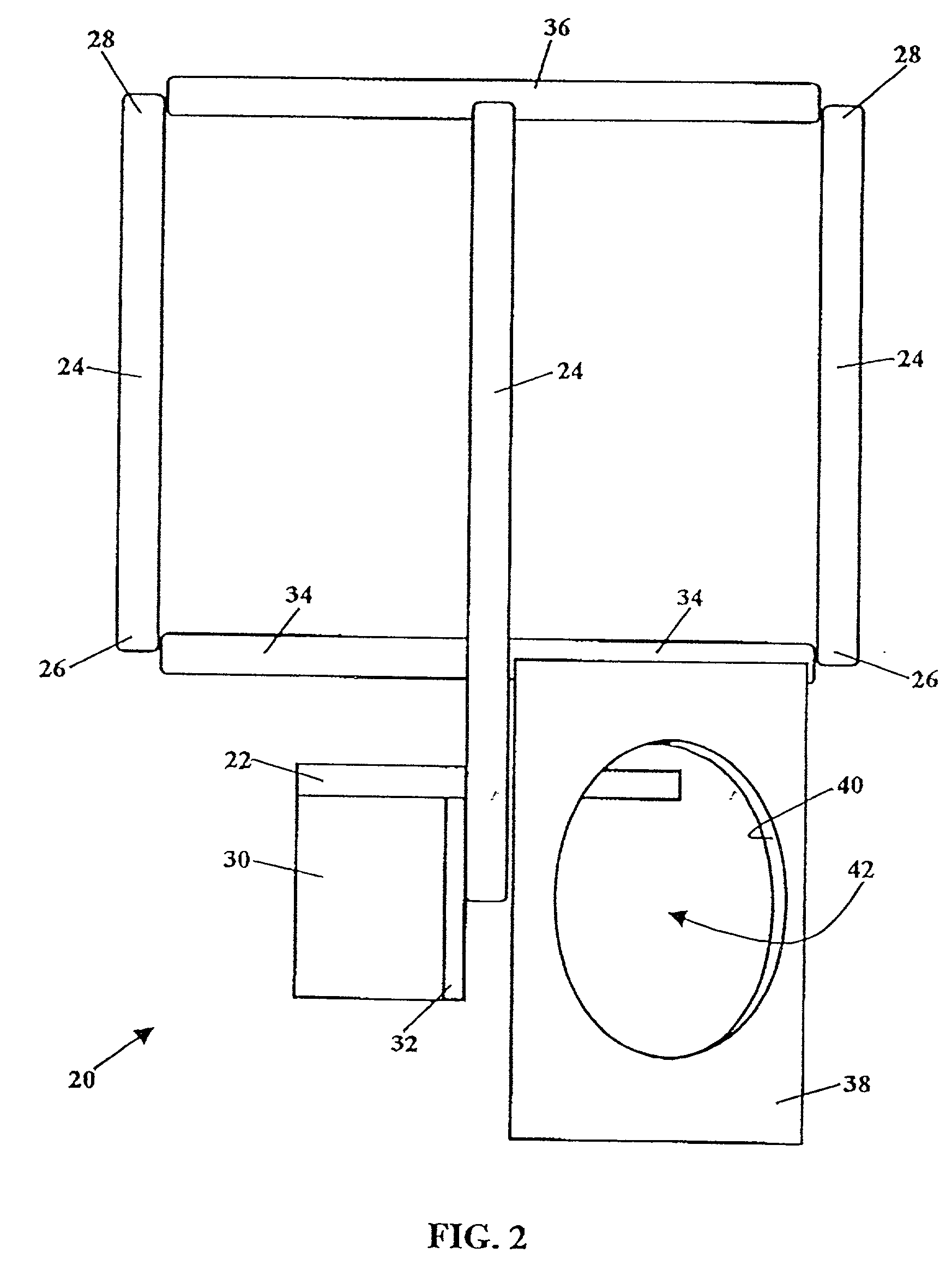

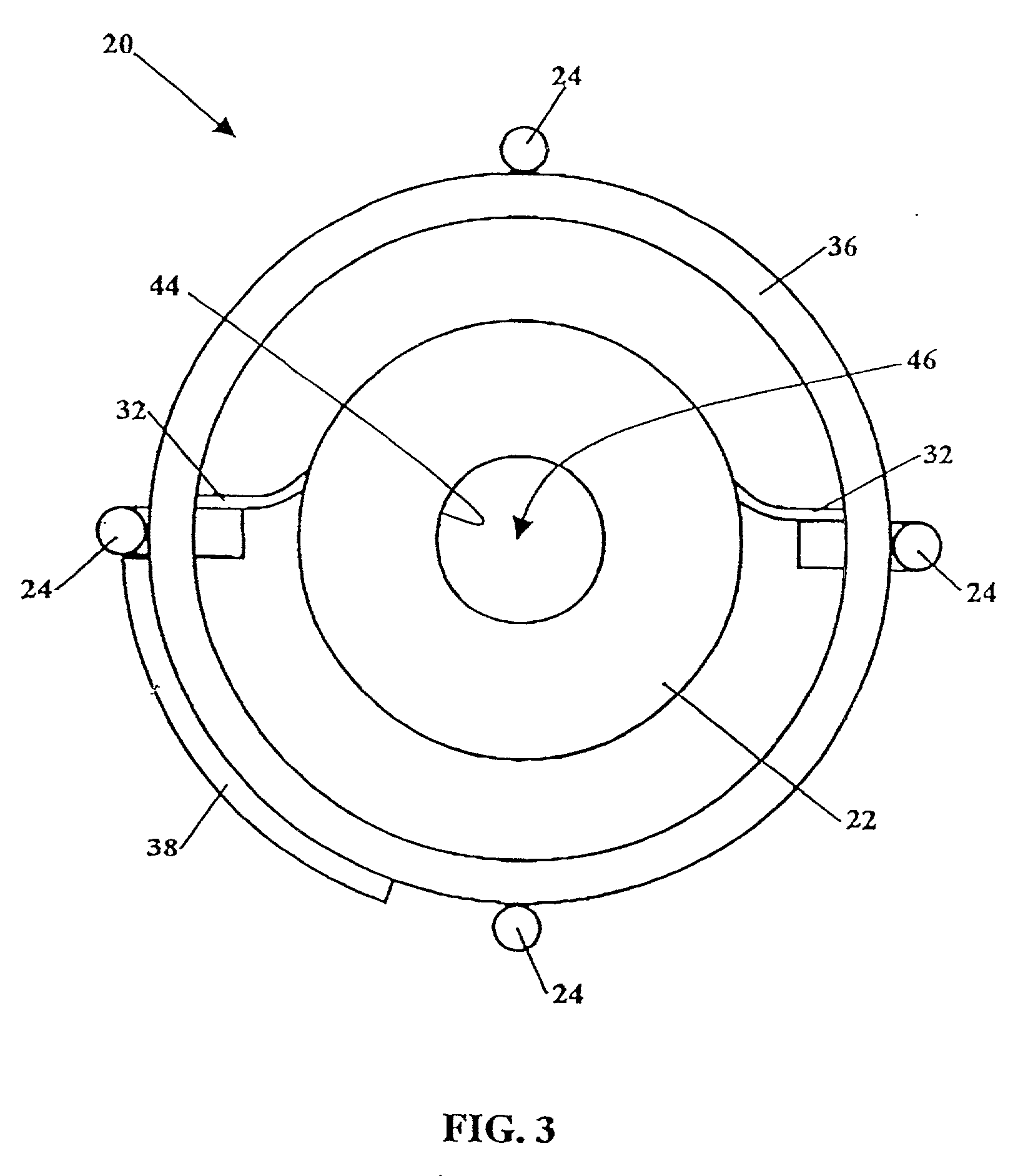

[0034] One embodiment of the head ring 20 is further illustrated by the following non-limiting example. This particular non-limiting example of the head ring 20 is sized for oxygen dispensing pressure vessels used in the airline industry. While this example is sized for use in the airline industry, the dimensions given below may vary for other applications. The head ring 20 shown in FIGS. 1-4, and further shown in FIGS. 6-8 , has an overall height 70 (FIG. 6) in the range of about 5 inches to about 8 inches, preferably in the range of about 6 inches to about 7 inches, to protect the valving assembly 12. In particular, the head ring 20 protects the regulator 14, which is a compact regulator design such as part number 165408DA produced by Precision Medical, Inc. or part number CP540-8UNBR-SH produced by Contemporary Products, Inc. The first ring 34 and the second ring 36 each have an outer diameter 72 (FIG. 7) in the range of about 3 inches to about 5 inches. The first ring 34 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com