Oscillator that uses thermostatic oven

a thermostatic oven and oscillator technology, applied in the field of oscillators, can solve problems such as equipment failure, increase in a substantial rise time, and frequency increas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

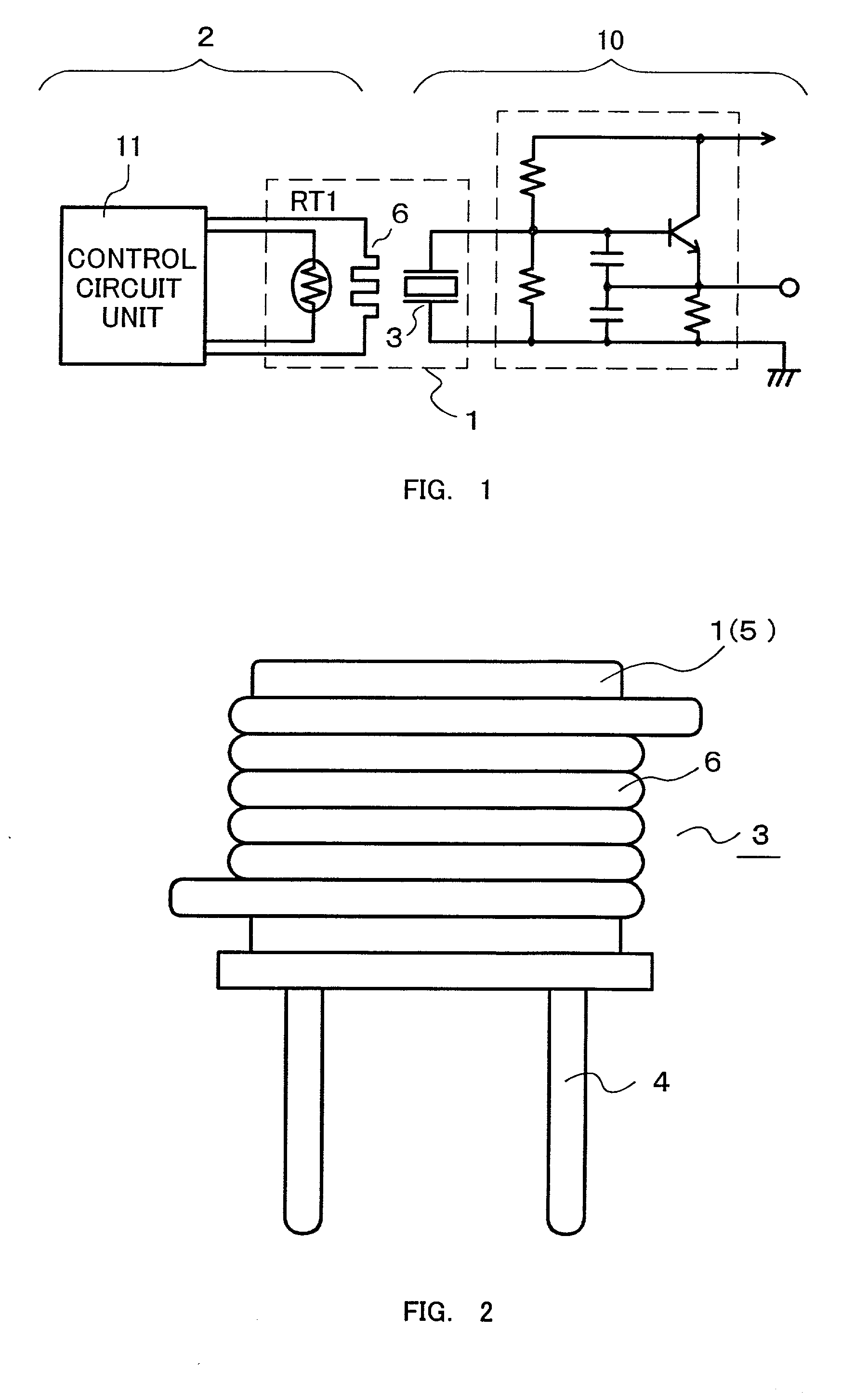

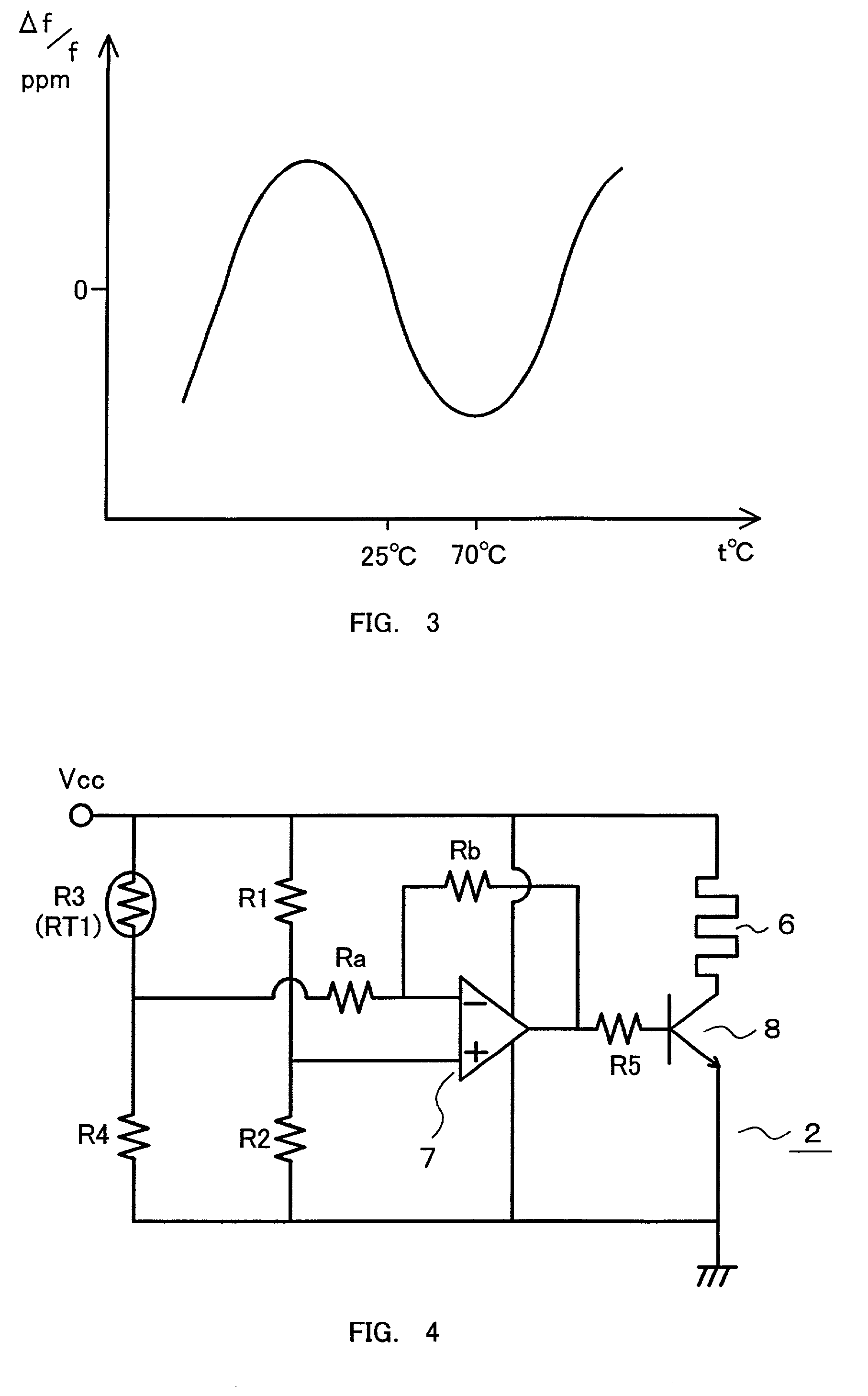

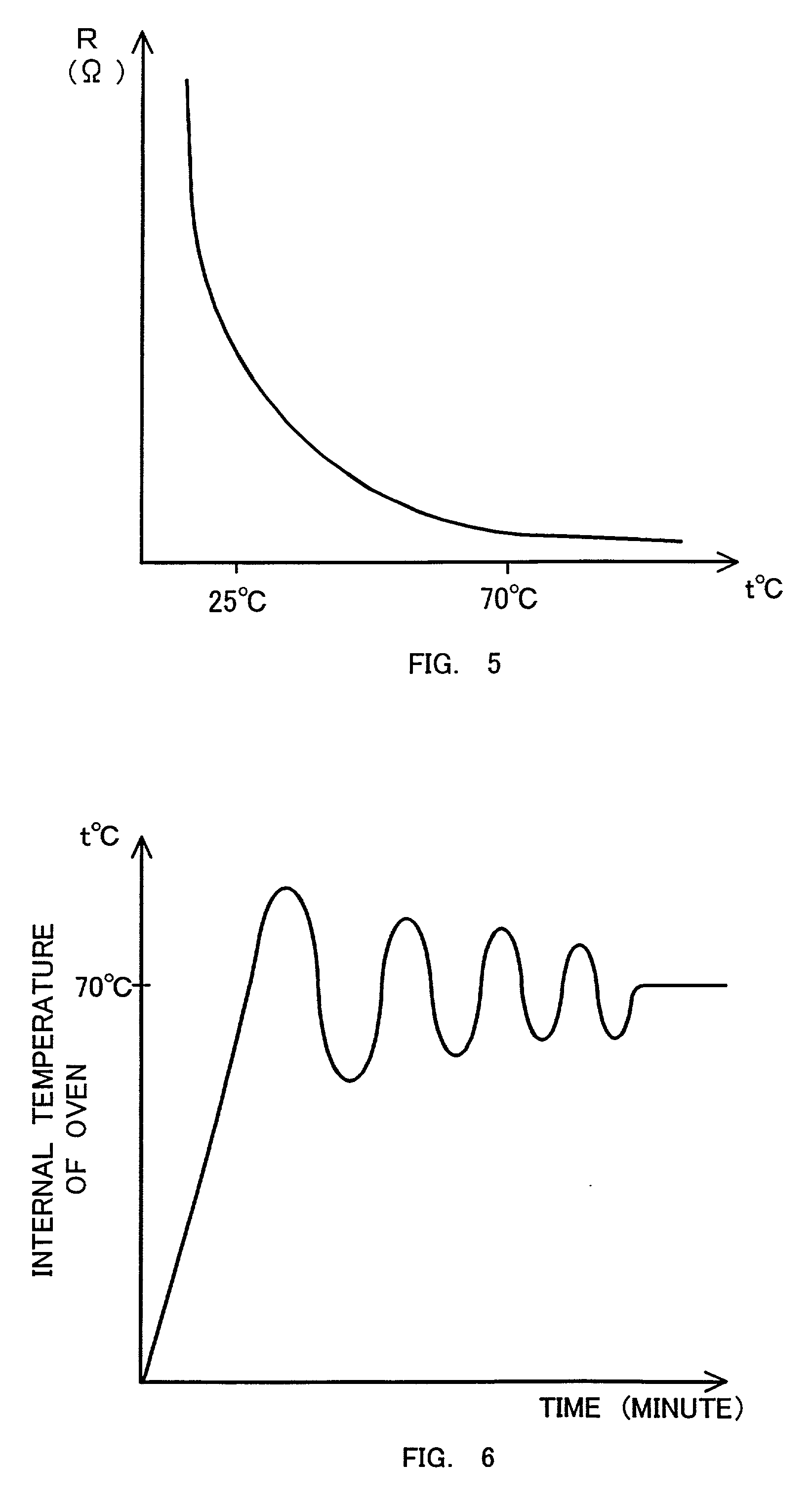

[0027] Next, preferred embodiments of the present invention will be described with reference to the drawings.

[0028] An oven-controlled oscillator of a preferred embodiment of the present invention shown in FIG. 7 has a similar configuration to that of the conventional oven-controlled oscillator shown in FIGS. 1 to 4 and includes crystal oscillation circuit 10 of a Colpitts type circuit configuration, thermostatic oven 1 in which quartz-crystal element 3 is accommodated, heater 6 for heating the inside of thermostatic oven 1, and heat source control circuit 2 for controlling current to flow through heater 6. The oven-controlled oscillator of the present embodiment, however, is different from the conventional oven-controlled oscillator in that heat source control circuit 2 has a different circuit configuration. FIG. 8 shows the circuit configuration of heat source control circuit 2 in the oven-controlled oscillator of the present embodiment. In FIGS. 7 and 8, the same components to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com