Method for making an insulating film

a technology of insulating film and film layer, which is applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical equipment, etc., can solve problems such as metal wiring corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

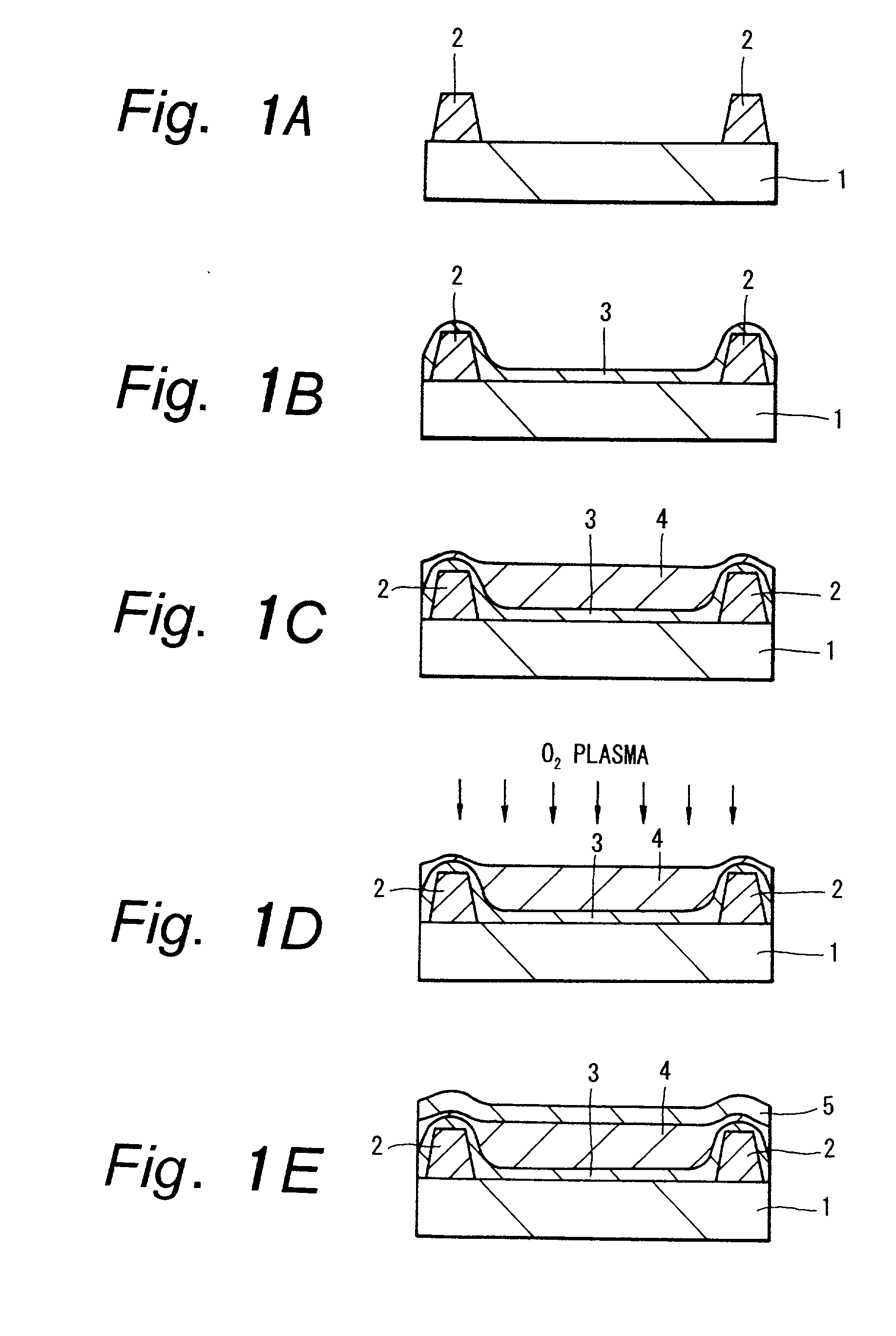

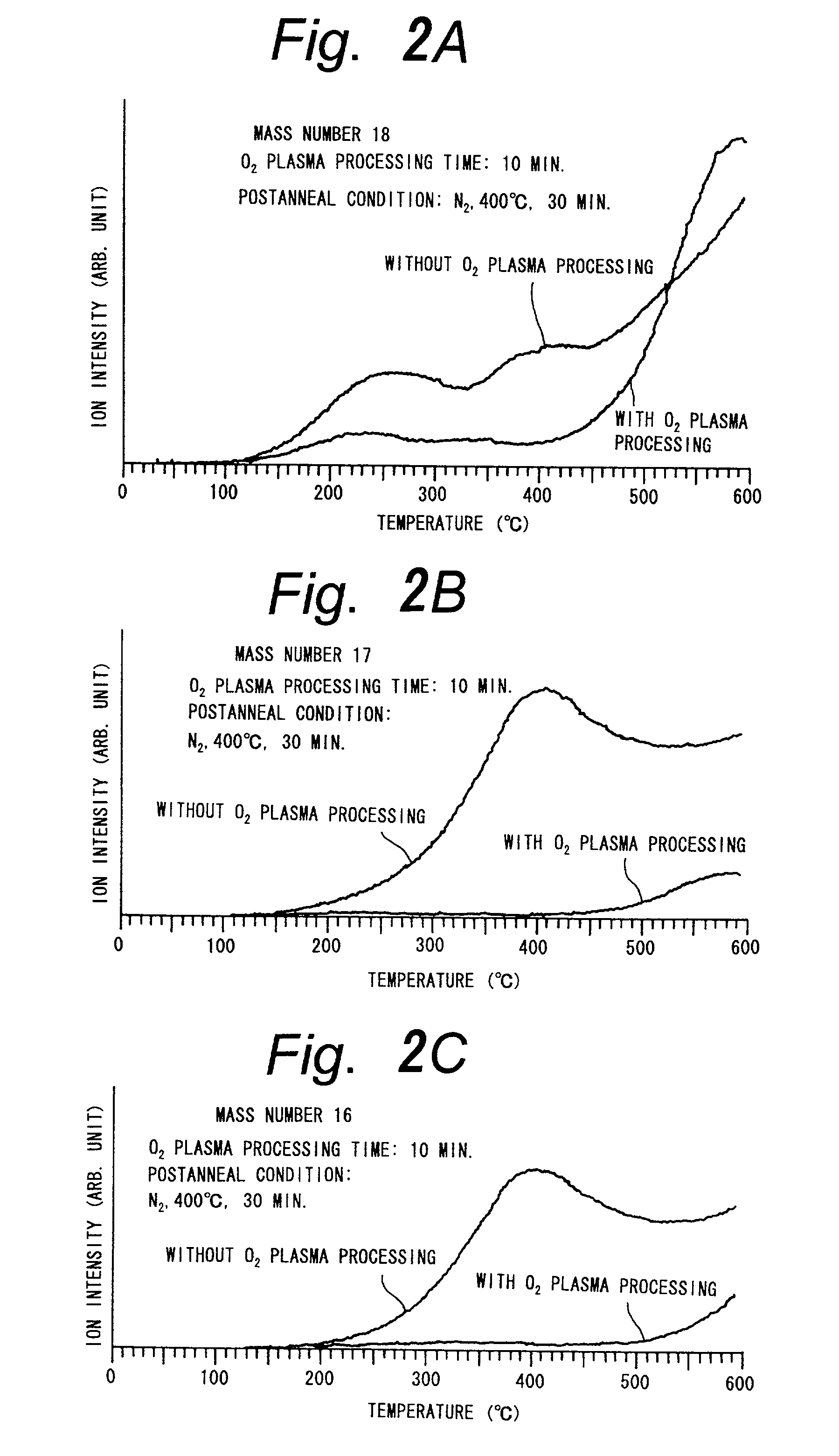

first embodiment

[0051] As explained above, substantially all H.sub.2O can be removed from the surface of the inter-layer insulating film 4 by treating the inter-layer insulating film 4 by O.sub.2 plasma processing after making the inter-layer insulating film 4 as a fluid film. Therefore, even when the SiO.sub.2 film 5 is made as a cap layer directly on the inter-layer insulating film 4 by plasma CVD, NH.sub.3 produced in vapor by plasma during the process is never incorporated into the inter-layer insulating film 4. As a result, corrosion of the Al alloy wiring 2 or the problem of poisoned via do not occur.

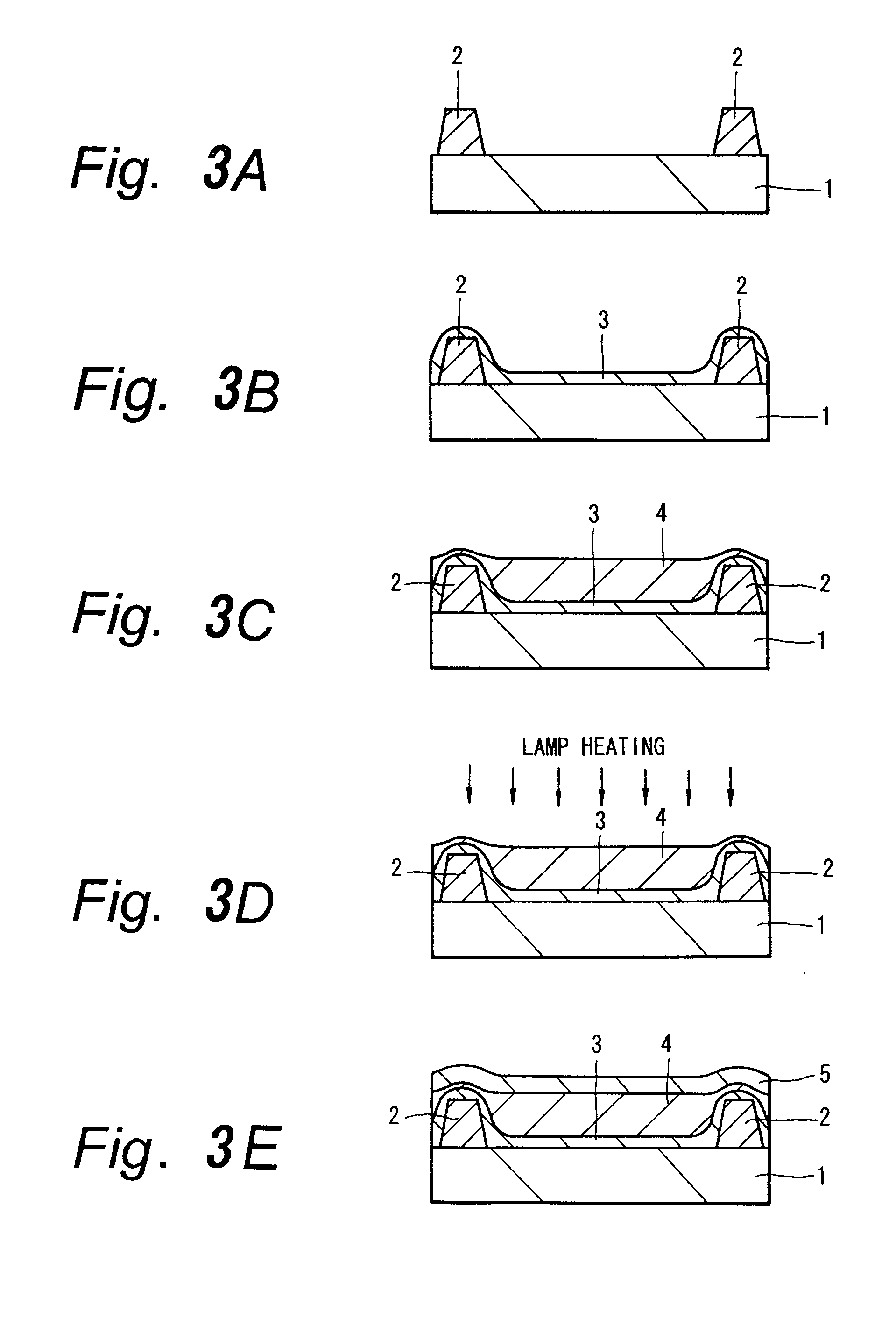

second embodiment

[0052] FIGS. 3A through 3E show a method for making an inter-layer insulating film according to the invention.

[0053] In the embodiment shown here, the Al alloy wiring 2 is formed on the Si substrate 1 having formed a device and covered with an inter-layer insulating film previously as shown in FIG. 3A,.

[0054] Next, as shown in FIG. 3B, a non-fluid SiO.sub.2 film 3 is made as a base layer on the Si substrate 1 by plasma CVD using SiH.sub.4 and N.sub.2O, for example, as source materials.

[0055] Next, as shown in FIG. 3C, a fluid inter-layer insulating film 4 is made by low pressure CVD using Si(CH.sub.3)H.sub.3 and H.sub.2O.sub.2, for example, as source materials. The steps heretofore are the same as those of the first embodiment.

[0056] Next, as shown in FIG. 3D, the surface of the inter-layer insulating film 4 is heated by lamp heating, namely by using radiant heat from a lamp heater, to cure the surface of the inter-layer insulating film 4 by rapid thermal annealing in a short time. ...

third embodiment

[0068] FIGS. 4A through 4E show a method for making an inter-layer insulating film according to the invention.

[0069] In the embodiment shown here, the Al alloy wiring 2 is formed on the Si substrate 1 having formed a device and covered with an inter-layer insulating film previously as shown in FIG. 4A.

[0070] Next, as shown in FIG. 4B, a non-fluid SiO.sub.2 film 3 is made as a base layer on the Si substrate 1 by plasma CVD using SiH.sub.4 and N.sub.2O, for example, as source materials.

[0071] Next, as shown in FIG. 4C, a fluid inter-layer insulating film 4 is made by low pressure CVD using Si(CH.sub.3)H.sub.3 and H.sub.2O.sub.2, for example, as source materials. The steps heretofore are the same as those of the first embodiment.

[0072] Next, as shown in FIG. 4D, the Si substrate 1 is set in a chamber 6 and heated while introducing O.sub.3 into the chamber to cure the surface of the inter-layer insulating film 4 by O.sub.3 annealing of the inter-layer insulating film 4. By the O.sub.3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com