Water heater usage profiling utilizing energy meter and attachable sensors

a technology of water heaters and sensors, applied in the field of water heater usage profiling utilizing energy meters and attachable sensors, can solve the problems of frequent user intervention, inconvenient implementation, and general consideration of standby loss of energy loss due to heat dissipation, and achieve the effects of reducing standby loss, effective optimization, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]While the present disclosure is made with reference to illustrative embodiments for particular applications, it should be understood that the disclosure is not limited thereto. Those skilled in the art with access to the teachings herein will recognize additional modifications, applications, and embodiments within the scope thereof and additional fields to which the disclosure would apply.

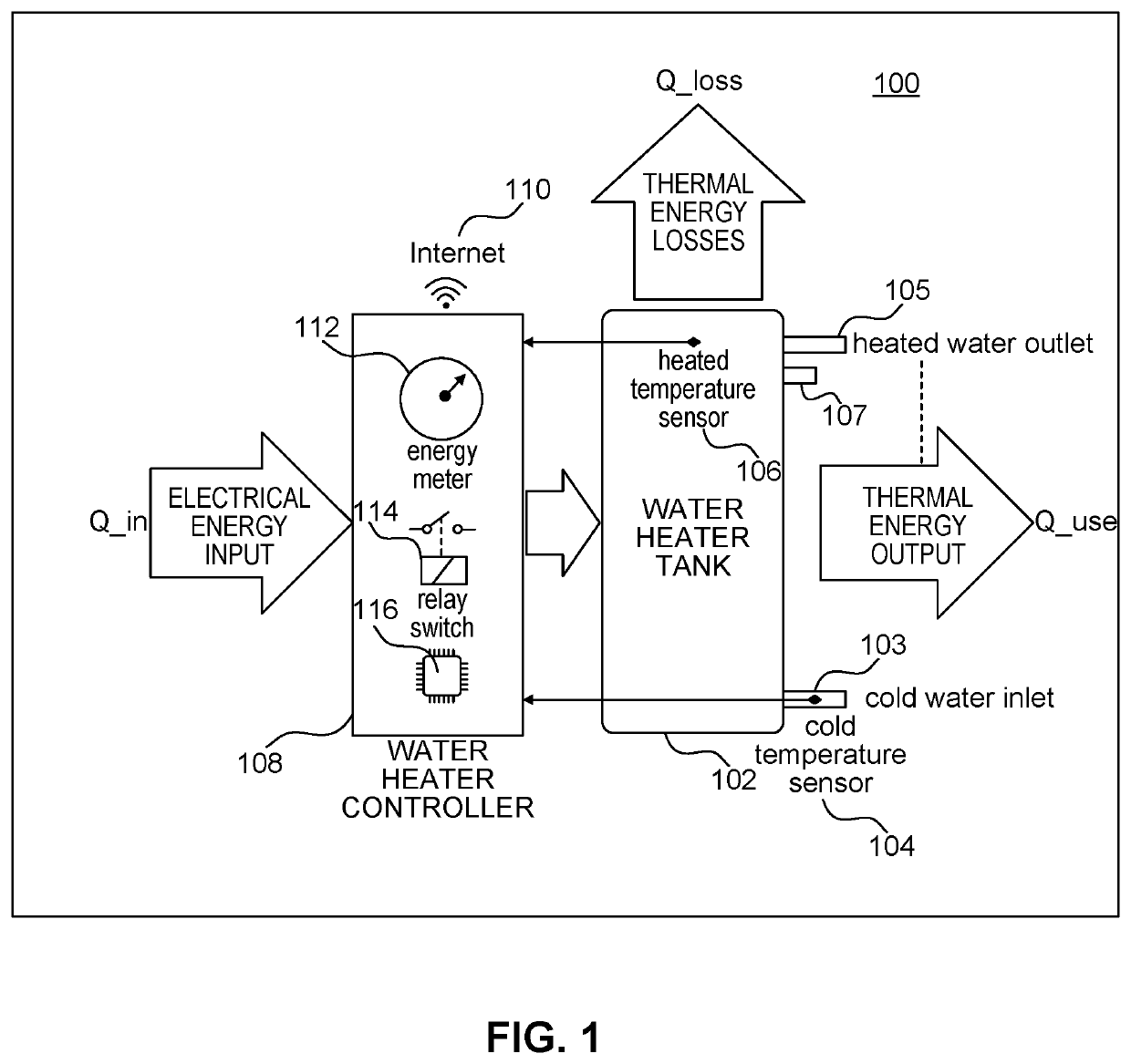

[0024]FIG. 1 is a schematic representation of a water heating system 100. Water heating system 100 can include water heater tank 102, cold water inlet 103, cold temperature sensor 104, heated water outlet 105, heated temperature sensor 106, T&P valve 107, and water heater controller 108. Heating elements utilizing electricity, gas, oil, or other energy sources can be immersed in water heating system 100 and are not illustrated in FIG. 1 for simplicity. Water heater controller 108 can include internet 110, energy meter 112, relay switch 114, and microcontroller 116. In some embodiments, respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com