Metallic device for scanning near-field optical microscopy and spectroscopy and method for manufacturing same

a near-field optical microscopy and metal device technology, applied in the direction of measuring devices, scanning probe microscopy, instruments, etc., can solve the problems of aperture-snom systems exhibiting space resolution, power transmitted by optical fibers decreasing exponentially with diameter, and not yet applying snom techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

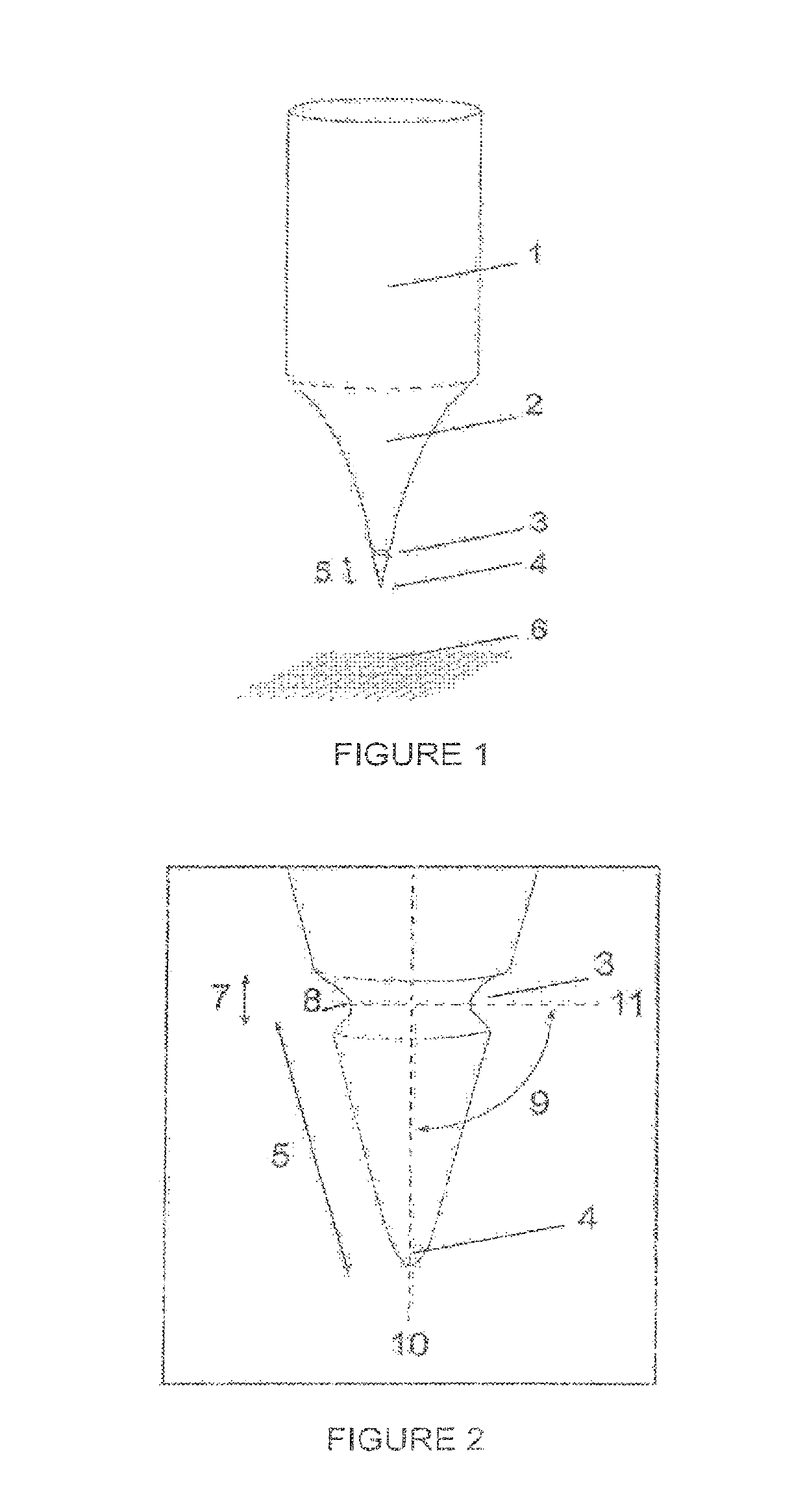

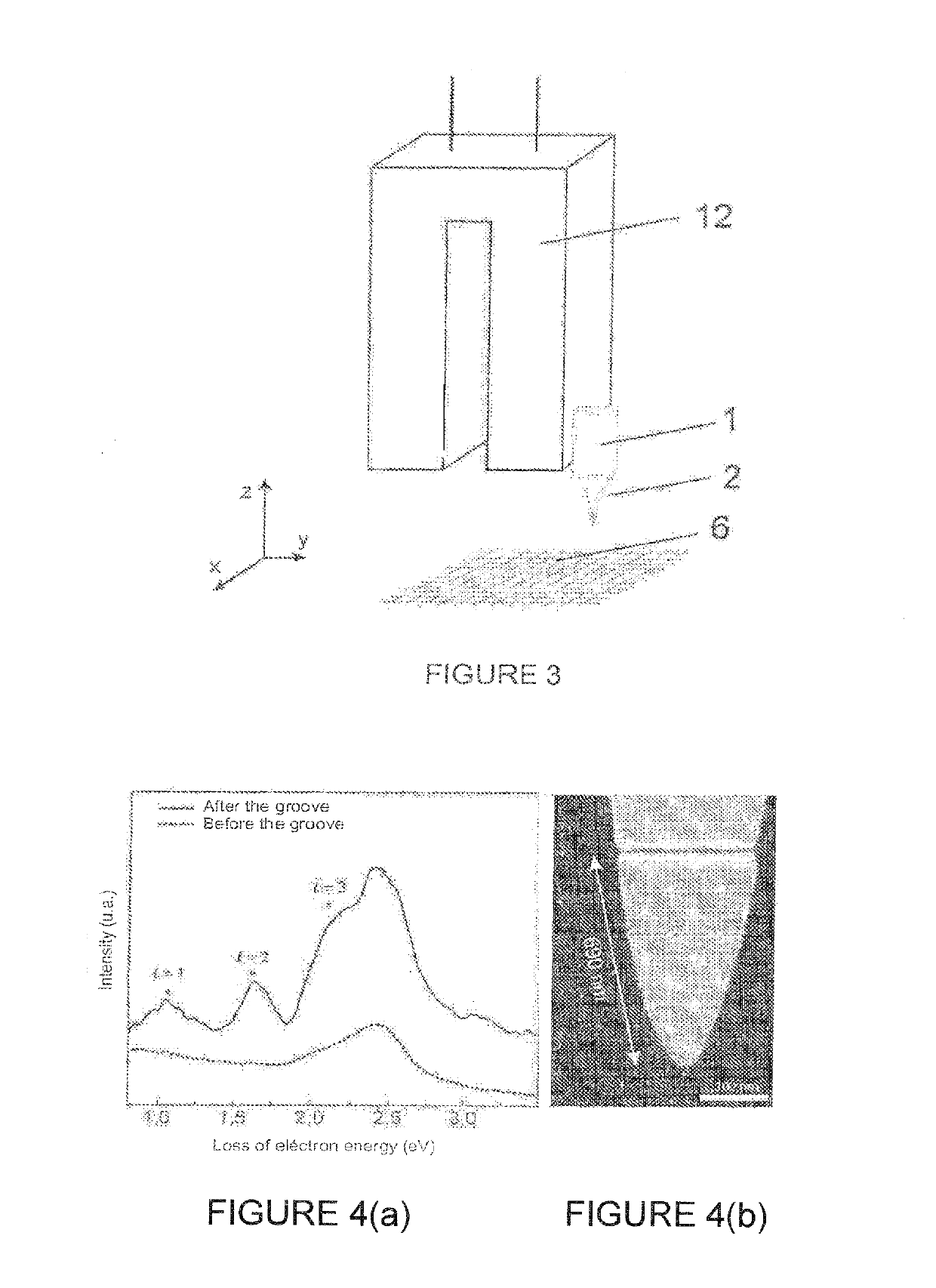

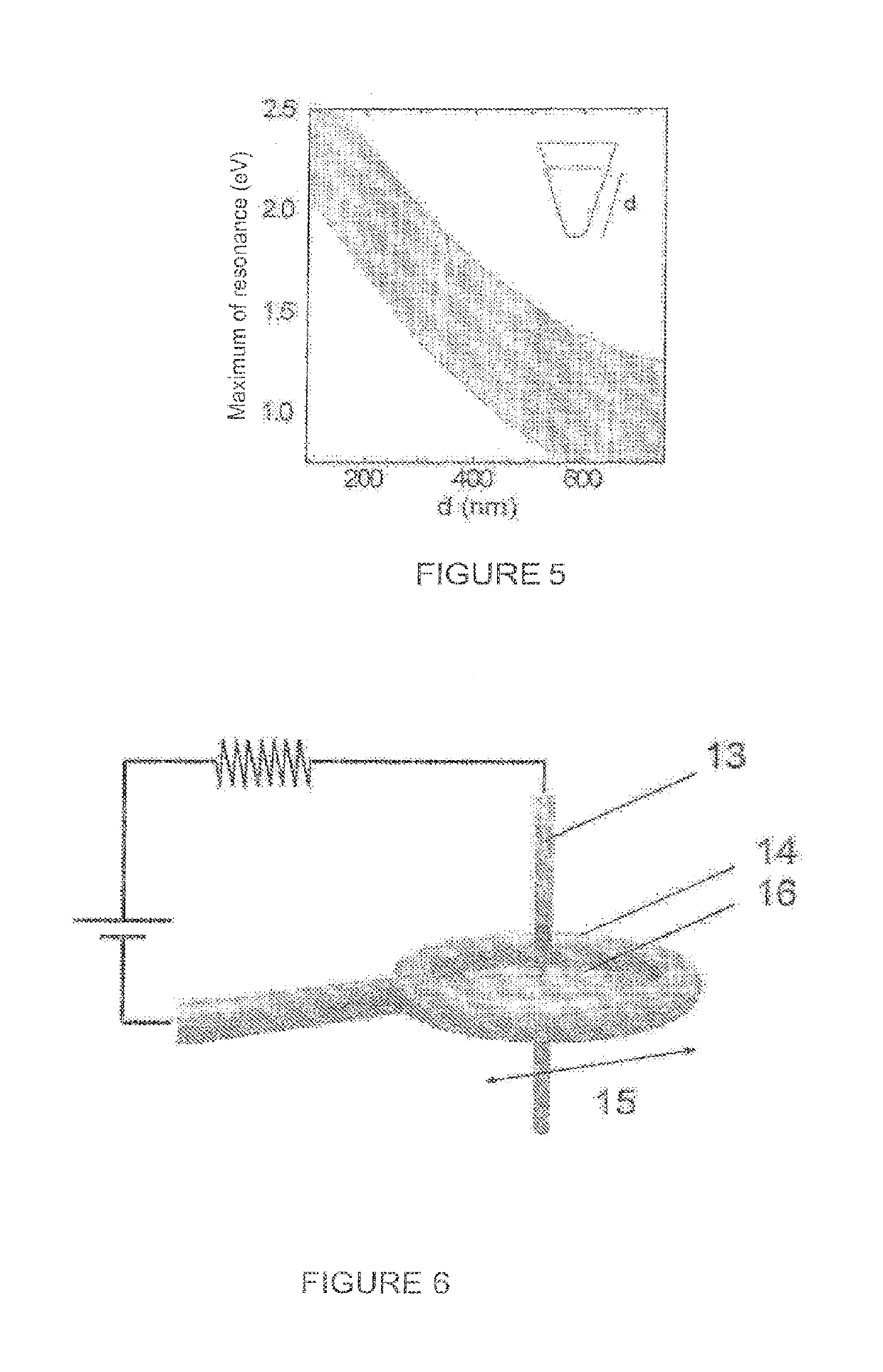

[0061]In this example one describes a process for manufacturing the metallic device with single trimming close to the nanometric end, starting from a gold probe made by electrochemical trimming of gold thread.

[0062]The manufacture of the device in the manner treated in this example is divided into three steps: (i) manufacture of the gold tip by electrochemical trimming, (ii) marking the trimming by FIB and (iii) joining to the tuning fork.

[0063]The manufacture of the gold tip may be carried out by the usual electrochemical method of trimming a gold thread, as treated in the reference: Klein, M.; Schwitzgebel, G. Review of scientific instruments 1997, 68, 3099-3103, and B. A. F. Puygranier and P. Dawson, 85 235 (2000). The gold thread should have thickness between 15 μm and 300 μm, preferably 100 μm, and exhibit purity higher than 99%, preferably higher than 99.995%. At a first moment, the thread should undergo a thermal treatment without the need to use controlled atmosphere (either...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com