Blade or vane for a rotary machine

A rotary and mechanical technology, applied in the direction of mechanical equipment, blade support components, engine components, etc., can solve the problems of being blocked in the matrix, blocking the matrix passage, reducing the cooling performance of the system, etc., to reduce the temperature difference and reduce the flow rate. The effect of increasing the flow area and improving the cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

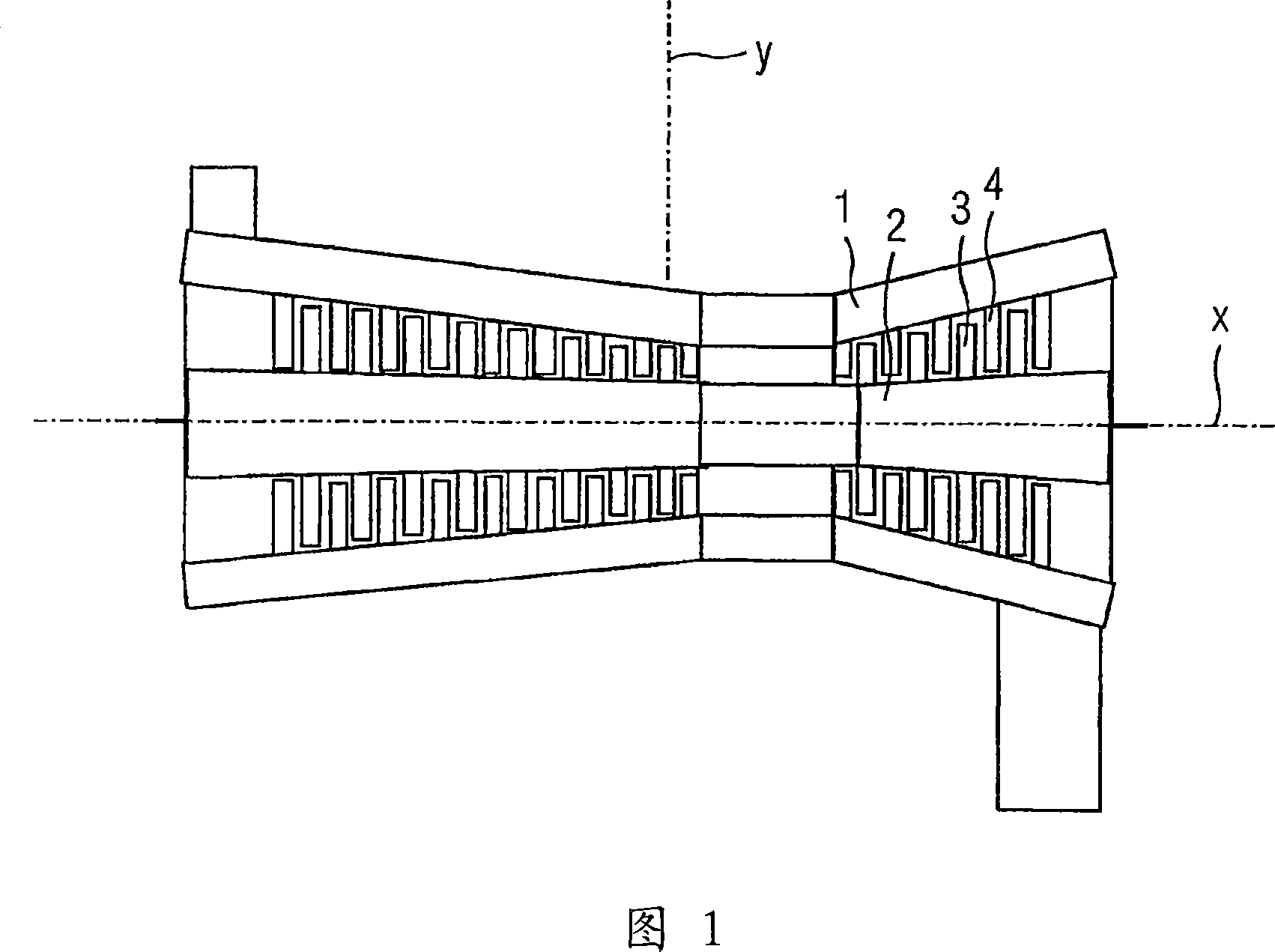

[0027] FIG. 1 schematically discloses a gas turbine with a stationary housing 1 and a rotor 2 rotatable within the housing 1 about an axis of rotation x. The gas turbine includes a plurality of rotor blades 3 mounted to a rotor 2 and a plurality of stationary vanes 4 mounted to a casing 1 .

[0028] Each rotor blade 3 and guide vane 4 thus forms a component of a gas turbine. Although the following description refers to the assembly in the form of a rotor blade 3 , it will be appreciated that the invention may also be applied to a vane 4 and that the features described hereinafter may also be included in a stationary vane 4 .

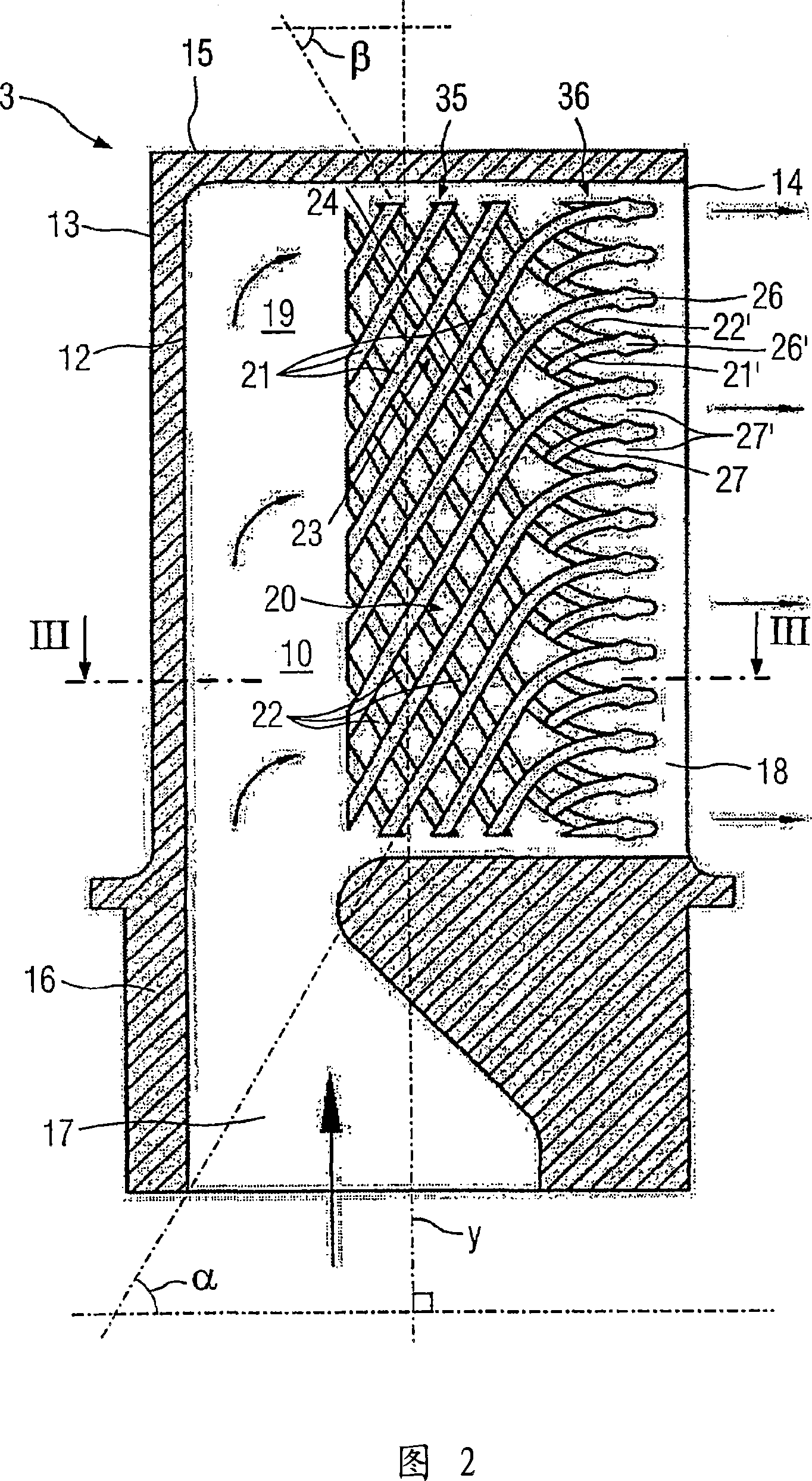

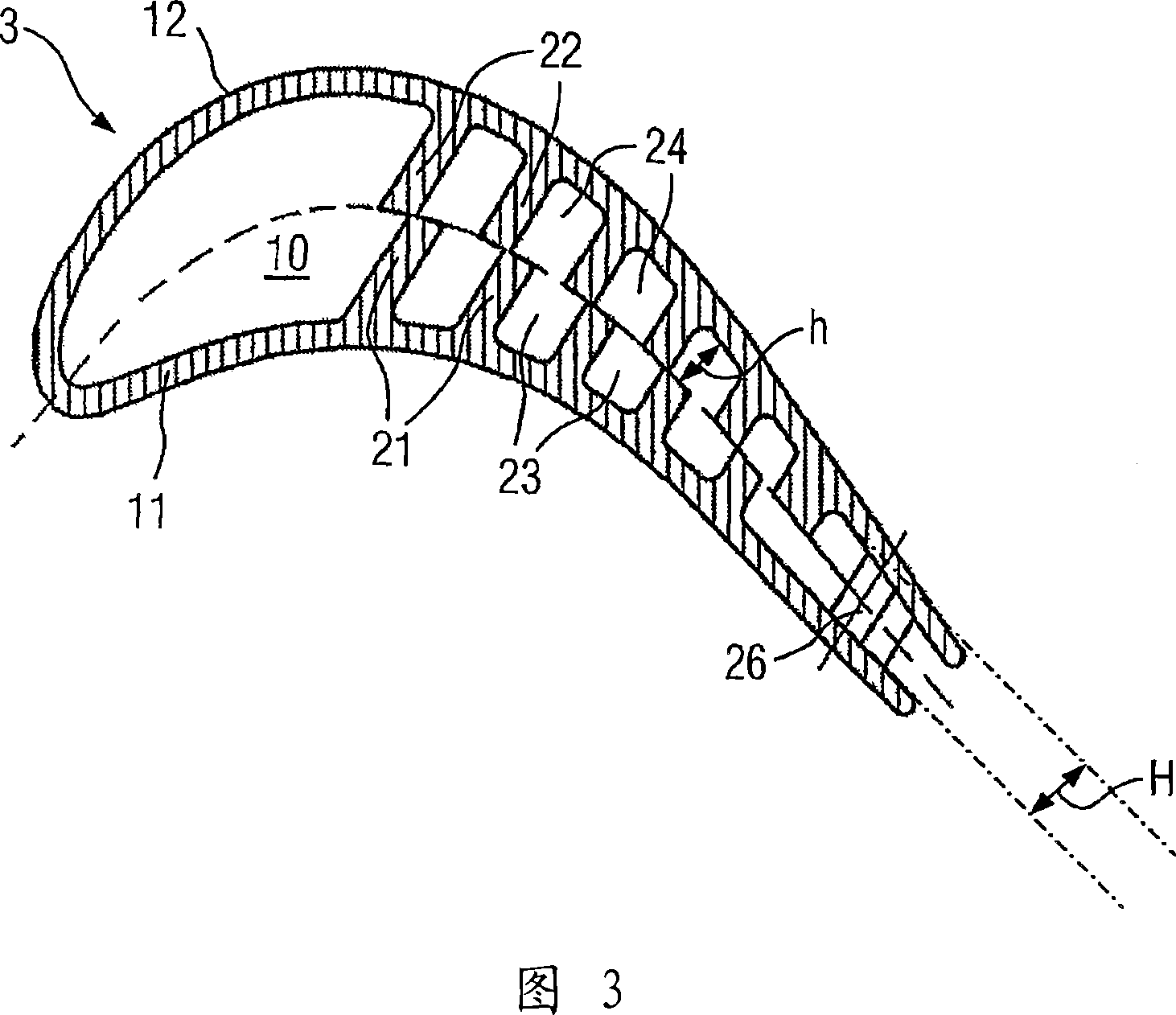

[0029] The above-mentioned assembly, namely in this case the rotor blade 3 , is further disclosed in FIGS. 2 and 3 . The rotor blade 3 comprises an inner space 10 delimited by a first wall 11 and an opposite second wall 12 . The first wall 11 and the second wall 12 face each other. The first wall 11 is arranged on the pressure side of the rotor blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com