Fuel product and process

A product, the technology of fuel spheres, applied in the direction of fuel, solid fuel, petroleum industry, etc., can solve the problems of increasing the total cost of forming coal briquettes, reduce operating costs, reduce the need for pretreatment or mixing, and avoid premixing or treatment the effect of the demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

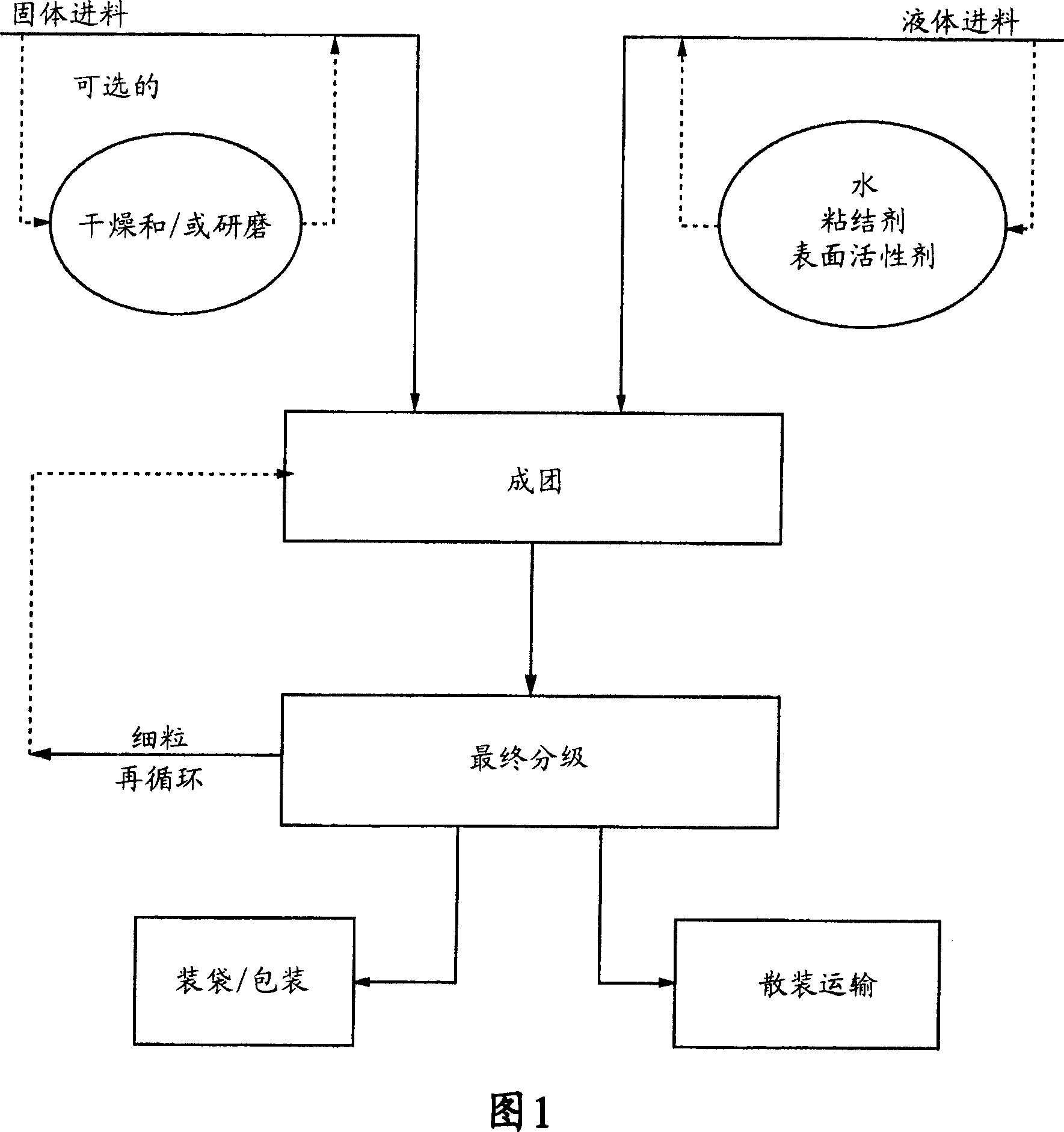

[0072] Fine coal recovery systems are a common part of modern coal processing operations, but cost-effective high-tonnage solutions are required for handling wet coal fines produced by different beneficiation processes.

[0073] The high capital and operating costs of briquetting plants prevent multiple operations from maximizing their coal reserves. Briquetting is a method in which certain types of materials are compressed under high pressure. Compression of the material results in a rise in temperature which causes the raw material to release various viscous substances.

[0074] There are inexpensive hydraulic briquetting machines that are designed to be operated for only a few hours per day. Larger mechanical presses are used for large-scale installations producing hundreds of kilograms per hour, but require about 200kWh of energy input (for drying and processing) per metric ton of briquette material. In countries where coal prices are already low, the cost of the briquet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com