Micro-stretching sample structure with elastic beam

A tensile specimen and micro-stretching technology, applied in the directions of strength properties, measuring devices, instruments, etc., can solve the problems of increasing the difficulty of micro-fabrication of test structures, sample calibration and displacement calibration, etc., and reduce torsion and displacement. The effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

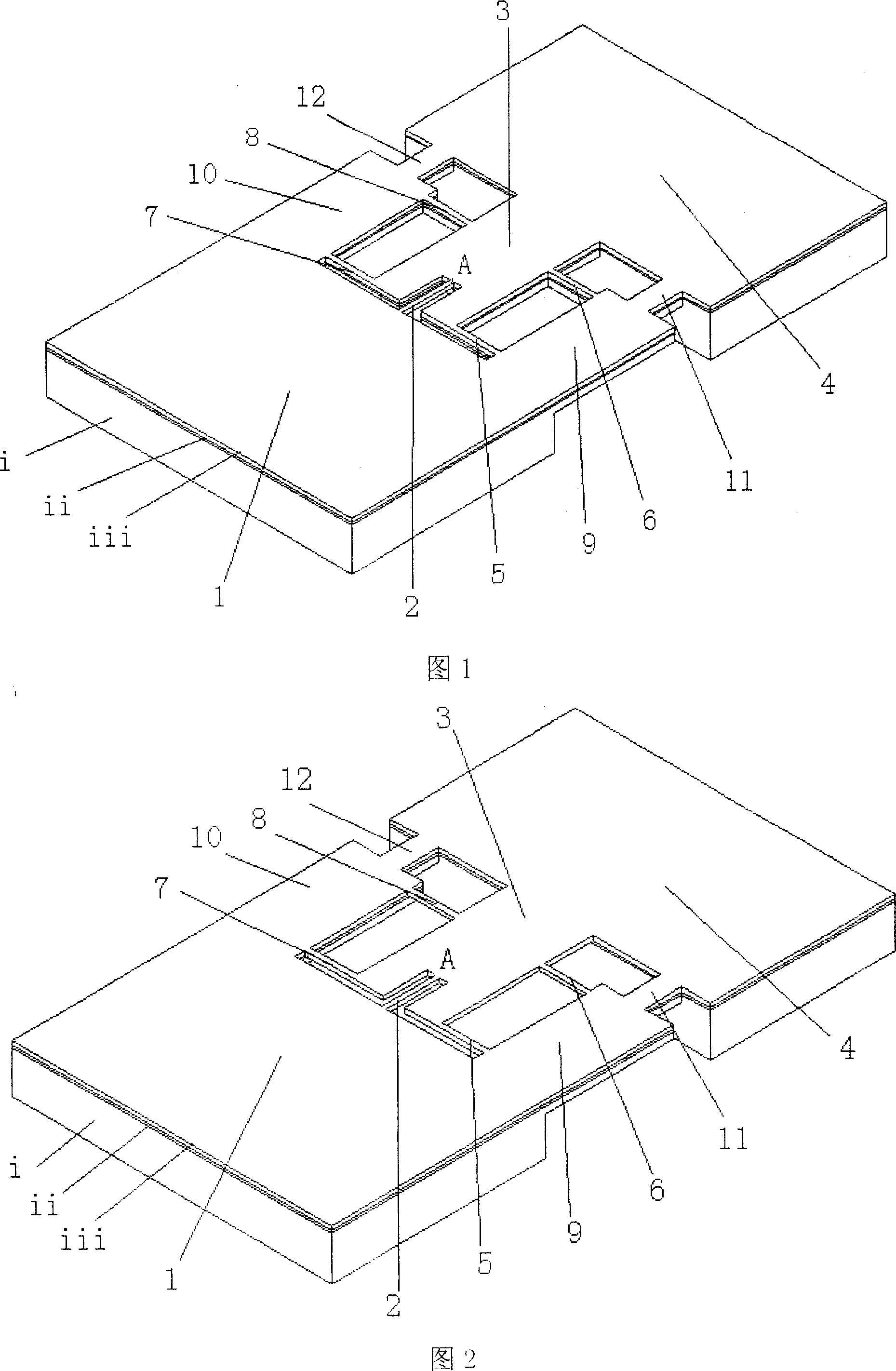

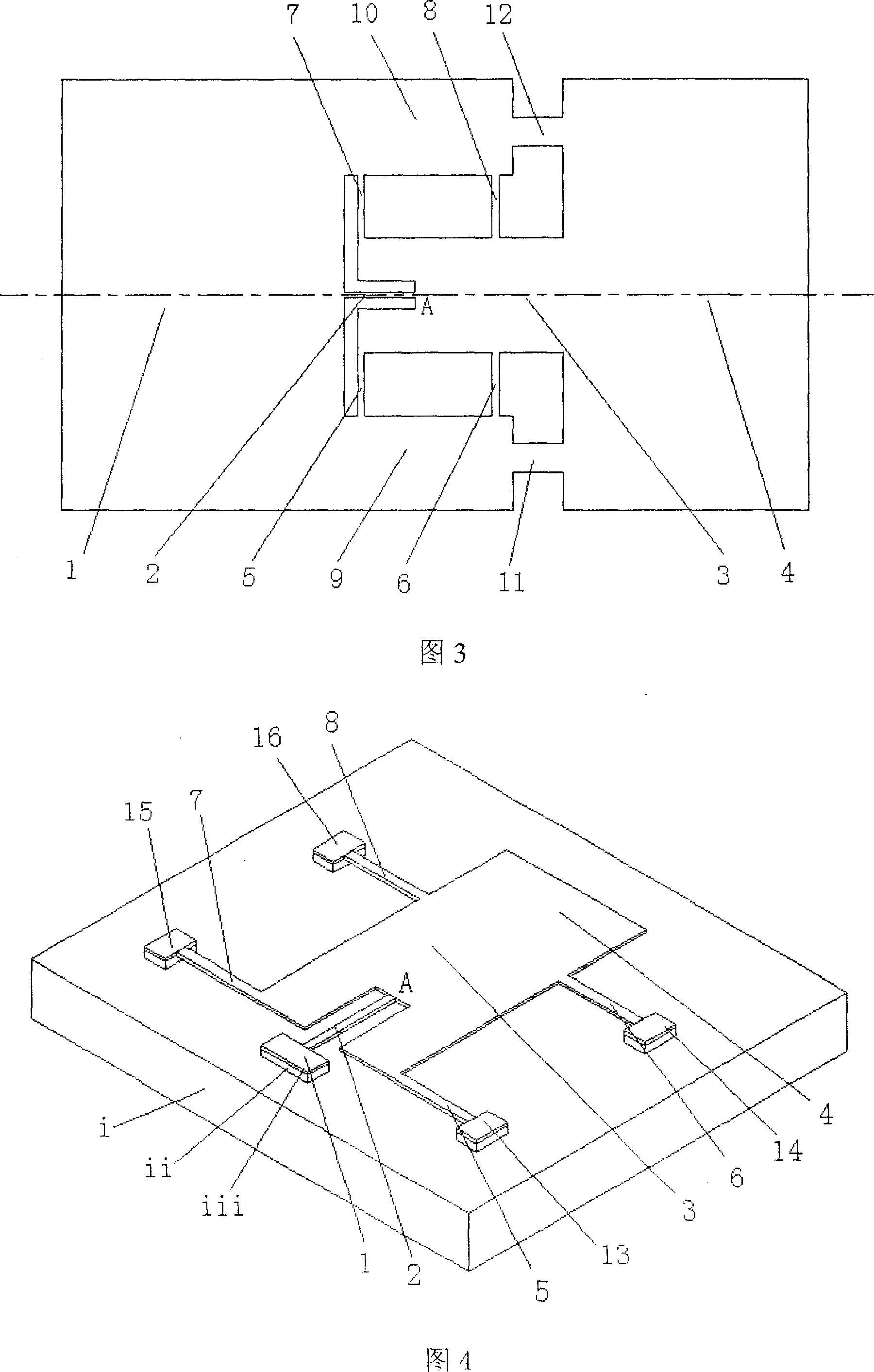

[0014] In conjunction with accompanying drawing 1, accompanying drawing 2, accompanying drawing 3 describe in detail the specific implementation of the present invention, when the micro-tensile sample structure of additional elastic beam is body micro-tensile sample structure, there is large-area flat plate in the middle part of its elastic support beam 3. One end is connected to the tensile sample 2, the other end is connected to the loading end 4, and the two sides are connected to linear elastic beams 5, 6, 7, 8. The connection point between the tensile sample 2 and the large-area flat plate 3 is close to the geometric center of the linear elastic beam. When doing the tensile test, the fixed end 1 in the micro-tensile sample structure is fixed on the static stage, the loading end 4 is fixed on the moving stage, the marking beam 5 is cut off, and the Tensile specimen. Under the action of linear elastic beams 5, 6, 7, 8, when the total loading force is at an angle of 5° to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com