Engine hydraulic tappet detection table

A hydraulic tappet and detection platform technology, which is applied in the direction of engine testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as inaccurate detection of engine hydraulic lifters, reduce human interference factors, and maintain The effect of low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

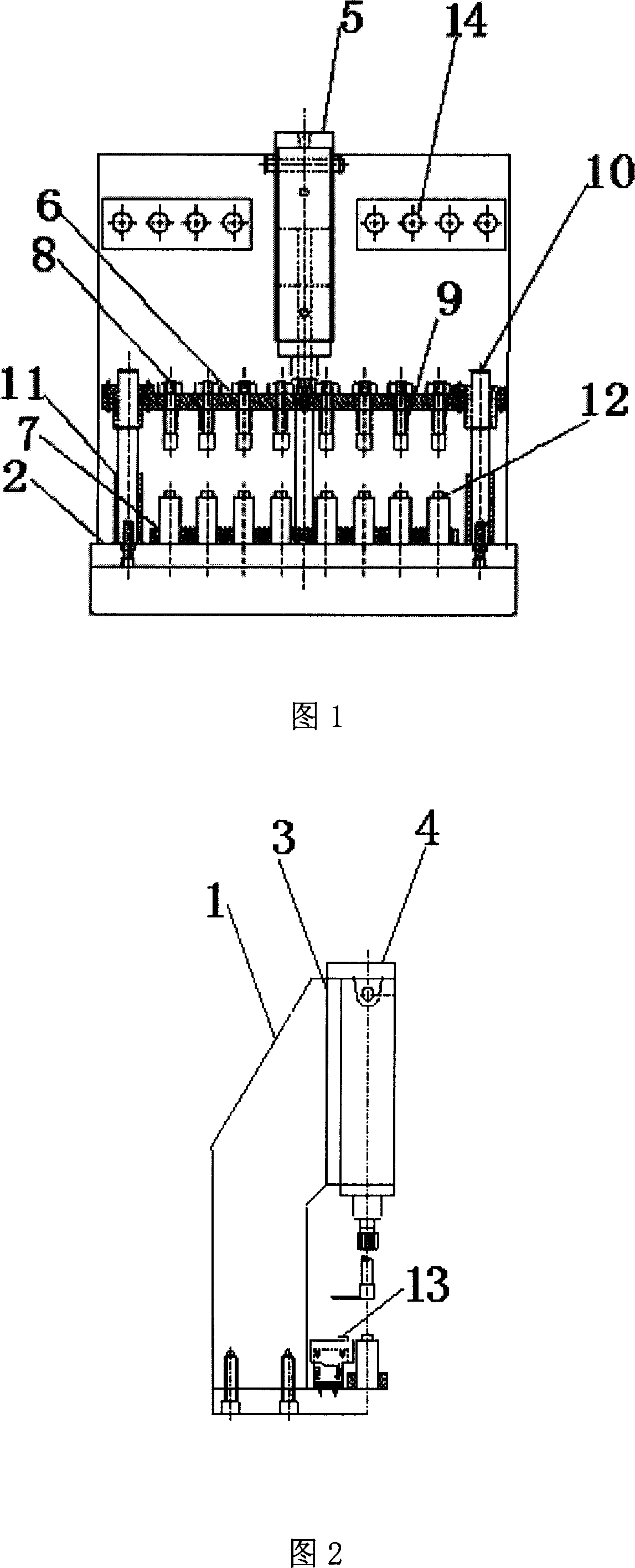

[0019] Shown in conjunction with accompanying drawing 1-2, a kind of engine hydraulic tappet detection platform, comprises tappet bottom plate 2, the column plate 1 that is connected with tappet bottom plate 2, indicating device and control device; Cylinder 5 assembly; on described tappet bottom plate 2, be provided with pressure-sliding mechanism; Said pressure-slide mechanism comprises guide post 10, beam 6 and positioning sleeve 7; Described guide post 10 is arranged at the end of tappet bottom plate 2, It is connected and fixed with the tappet base plate 2 by bolts, and the guide post 10 is connected with the beam 6 by a sliding sleeve. A detection mechanism is uniformly arranged on the beam 6, and the detection mechanism includes a push post 8, a nut at the upper end of the push post 8, a spring 9 at the lower end of the push post 8, and a jacking block. The positioning sleeve 7 is installed on the tappet bottom plate 2 and arranged on the corresponding surface of the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com