Prolease A defective yeast suitable for pure draft beer brewage and its usage method

A protease and defect-type technology, applied in the field of bioengineering, to solve the effects of poor foam stability, fast reduction speed and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

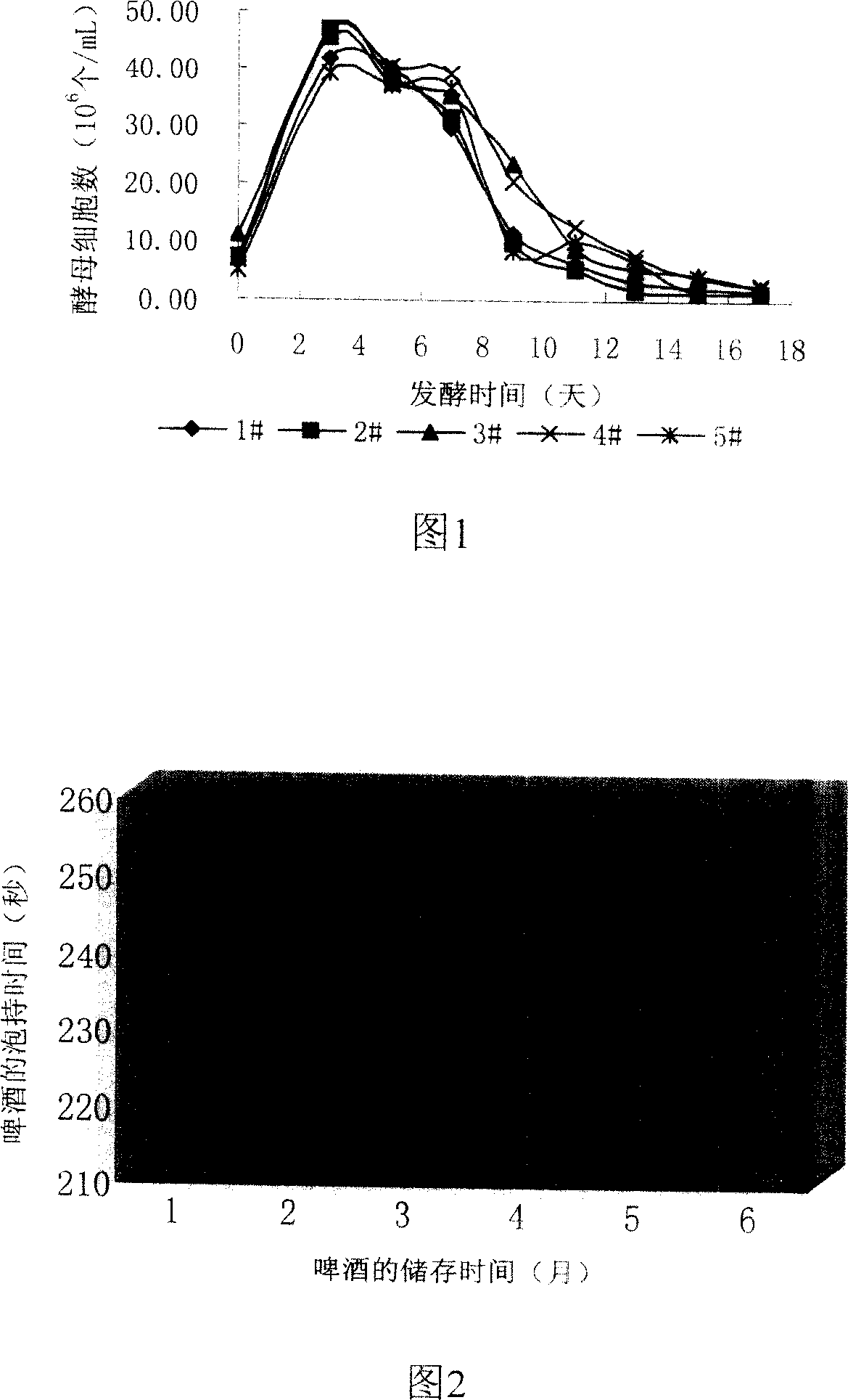

[0020] Example 1 Brewing of pure draft beer with CGMCC No1858

[0021] (1) Seed and expansion liquid: 11°P whole malt wort.

[0022] (2) Typed wort for production: malt: rice = 7:3, saccharification by leaching method, the final wort concentration is controlled to be 11°P; the α-amino nitrogen content of the wort is not less than 200mg / 100mL, and the oxygenation amount 12mg / L, wort inoculum: QD06-2 yeast cell concentration 1.8×10 6 -2.1×10 6 pcs / mL.

[0023] (3) Fermentation conditions: the main fermentation temperature is controlled at 9.5±0.5°C, and the temperature is raised to 12°C to reduce the diacetyl when the sugar is lowered to 4.2-4.5°P;

[0024] (4) Wine storage: The yeast was recovered after heating for 4 days, and after the diacetyl was reduced to 0.06 mg / L, the temperature was lowered to 0 °C; the waste yeast was discharged after one day, and the yeast was discharged every three days during the wine storage period.

[0025] (5) Membrane filtration and packagin...

Embodiment 2

[0030] Example 2 Bubble Hold Assay Tracking

[0031] The soaking time of the finished beer can always be higher than the national standard during the value preservation period, and it is still greater than 230S after 6 months. The tracking value of the soaking test is shown in Figure 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com