V-shape belt-type automatic transmission

A technology of automatic transmission and variable speed belt, applied in the direction of automatic clutch, clutch, transmission, etc., can solve problems such as large vibration, and achieve the effect of reducing vibration, increasing vibration period, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

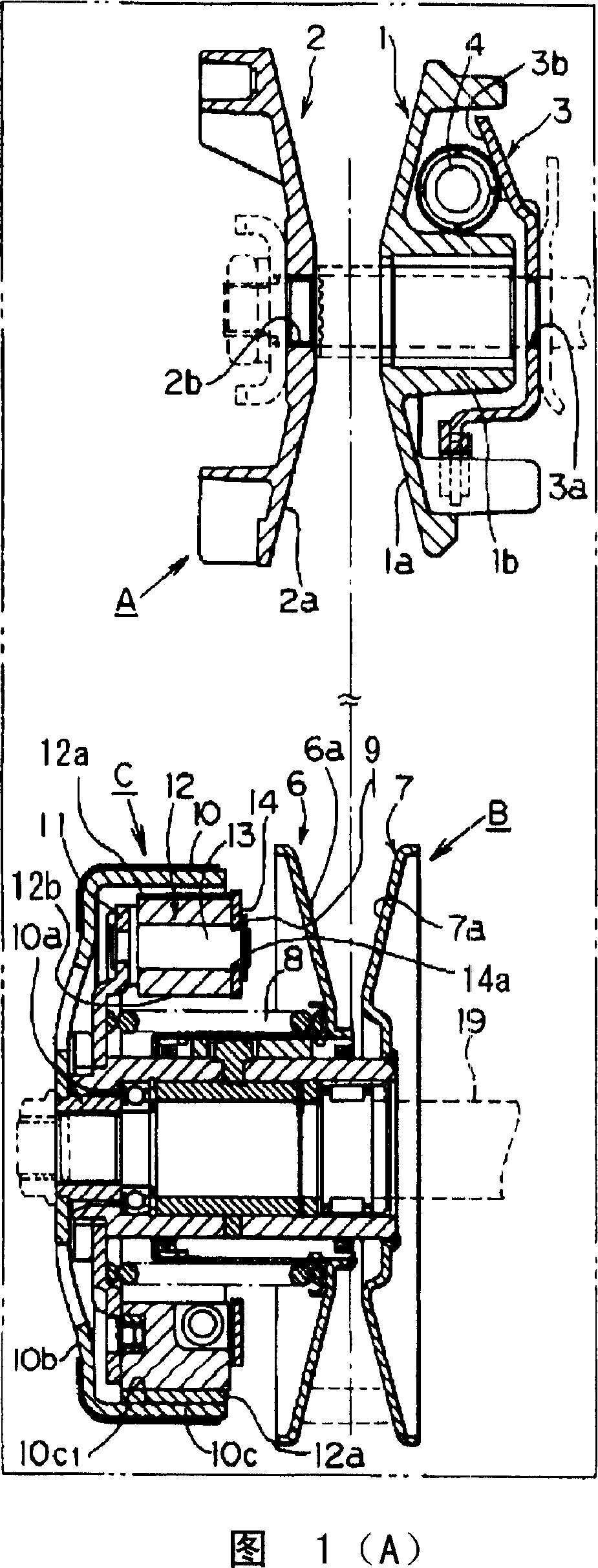

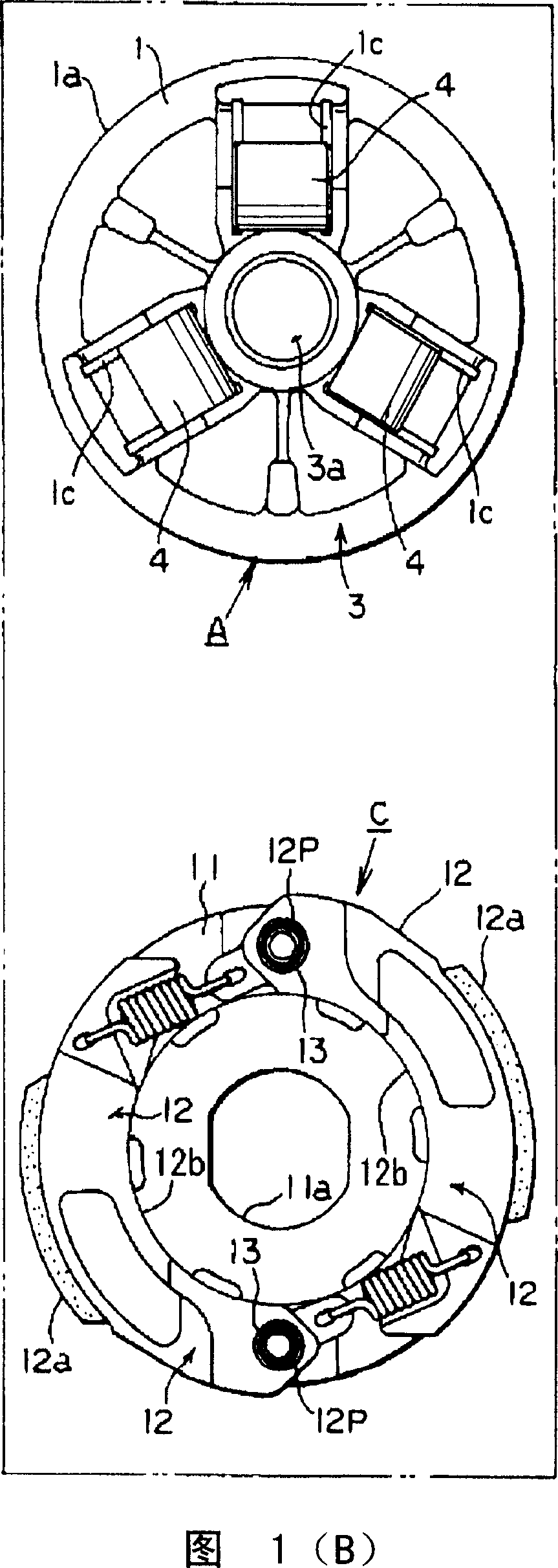

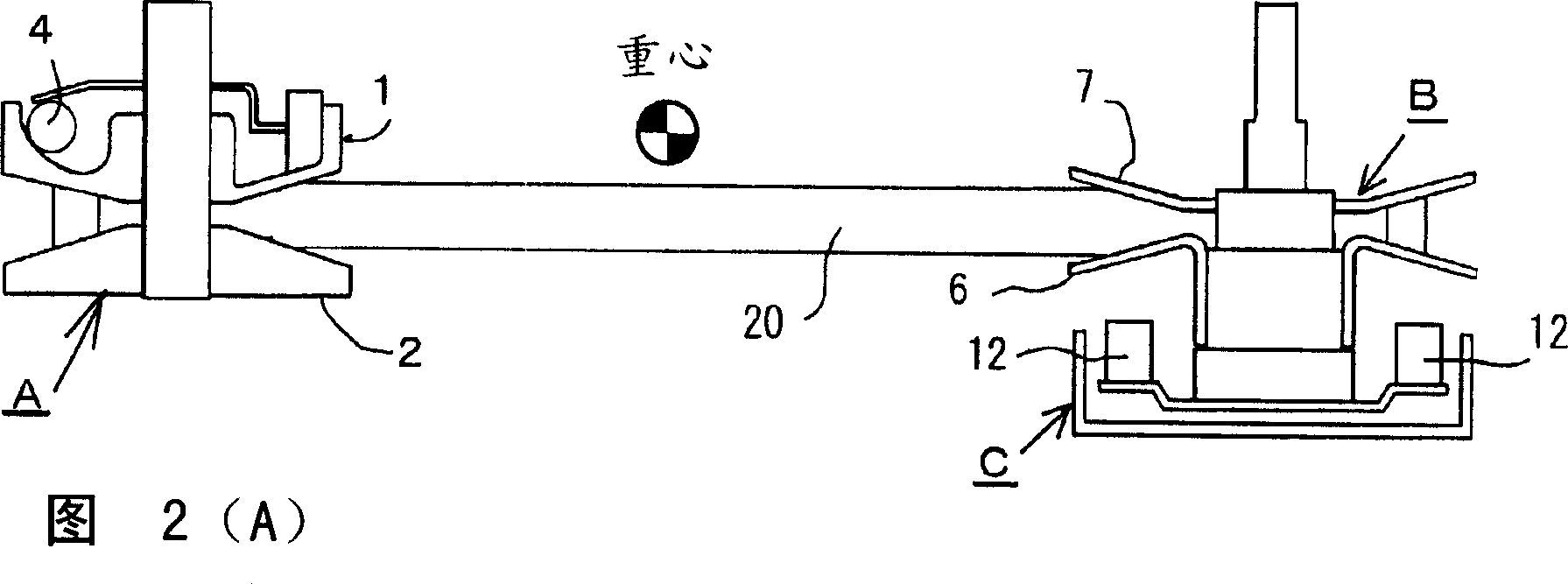

[0026] Hereinafter, embodiments of the present invention will be described based on the drawings. First of all, the structure of the device of the present invention is shown in Figures 1, 2 and so on. It is mainly composed of a driving side speed change pulley A, a driven side speed change pulley B, and a centrifugal clutch C. On this basis, an engine is added. As an engine assembly. The drive side speed change pulley A is mounted on the crankshaft on the engine side via the drive shaft. The drive-side variable speed pulley A is mainly composed of a movable pulley half 1, a fixed pulley half 2, and a centrifugal roller 4. The movable pulley half body 1 and the fixed pulley half body 2 are opposed to each other to form a set of pulleys. The movable pulley half 1 is formed of a substantially flat conical belt abutment plate 1a and a hub 1b, and the fixed pulley half 2 is also formed of a generally flat conical belt abutment plate 2a and a hub 2b.

[0027]The belt contact plate 1a an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com