Renovation technique of steam turbine rotor shaft fracture

A steam turbine rotor and process technology, which is applied in the direction of manufacturing tools, metal processing equipment, laser welding equipment, etc., can solve the problems of hidden dangers in the safe operation of the rotor, and the overall quality of the rotor shaft cannot be guaranteed 100%, achieving small thermal deformation and easy operation , strong normative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

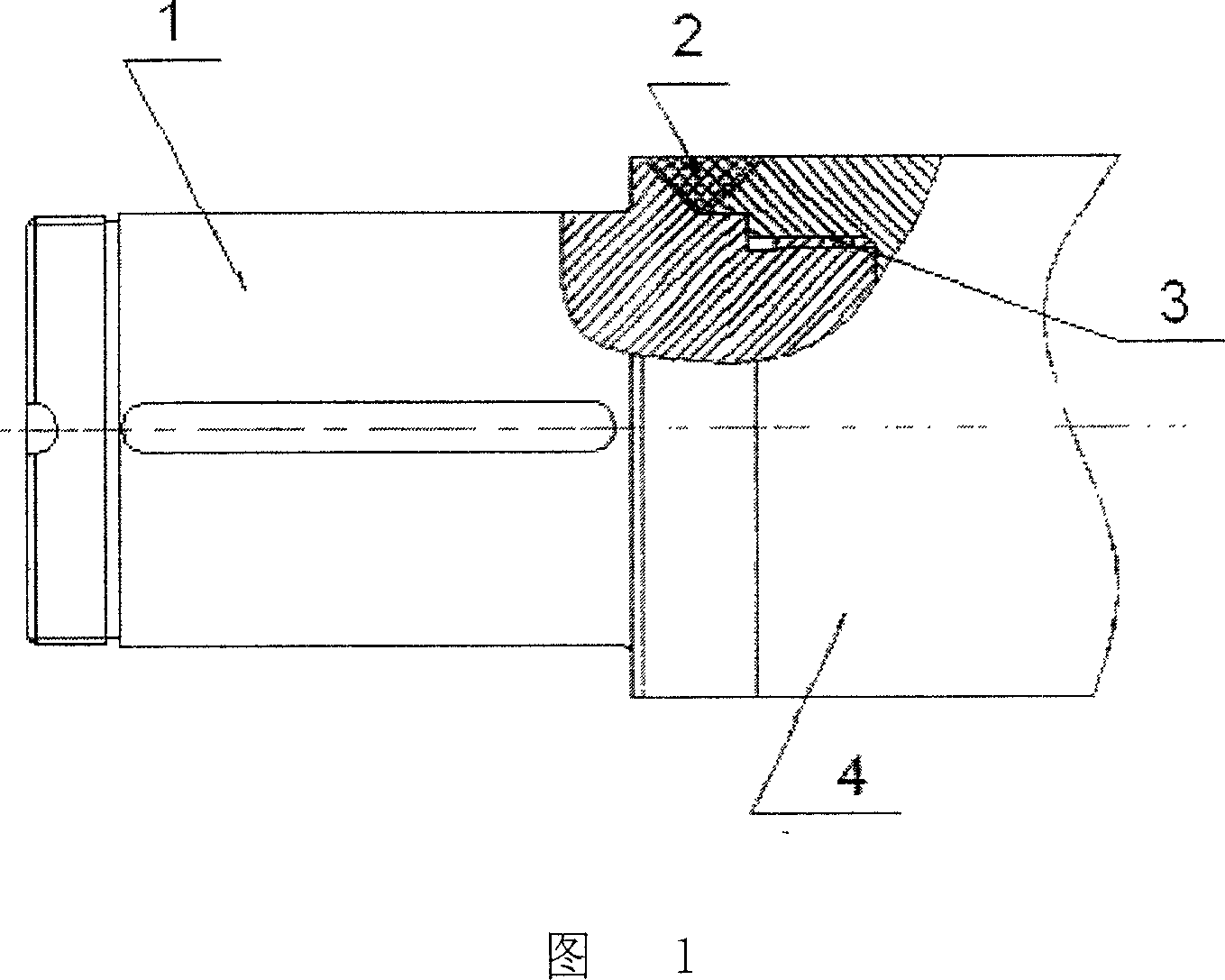

[0013] Example 1 Restoration process for steam turbine rotor shaft fracture

[0014] The process steps are as follows:

[0015] 1. Failure cause analysis, providing basis for the design of new parts, connection methods and specific dimensions of interface parts:

[0016] 1.1 Metallographic analysis of damaged parts;

[0017] 1.2 Analysis of rotor material composition;

[0018] 1.3 Determine the cause of the rotor shaft fracture by analyzing the results.

[0019] 2. Redesign a small part of the fracture

[0020] 2.1 Select the section with less stress as the location of the interface;

[0021] 2.2 According to the axial and radial loads borne by the rotor, it is decided to adopt the threaded connection plus laser cladding part method, and the core thread size and the laser cladding groove size are determined according to the load;

[0022] 2.3 Survey and map the dimensions of other parts of the fractured parts;

[0023] 2.4 Design according to surveying and mapping result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com