Detecting machine for automobile chair slide rail angle regulator strength and its detecting process

An automobile seat slide rail and recliner technology, which is applied to the field of automobile interior parts, can solve the problems of non-standard test calculation, large test function error, cumbersome test procedure, etc., and achieves good test quality, complete test function and comprehensive full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

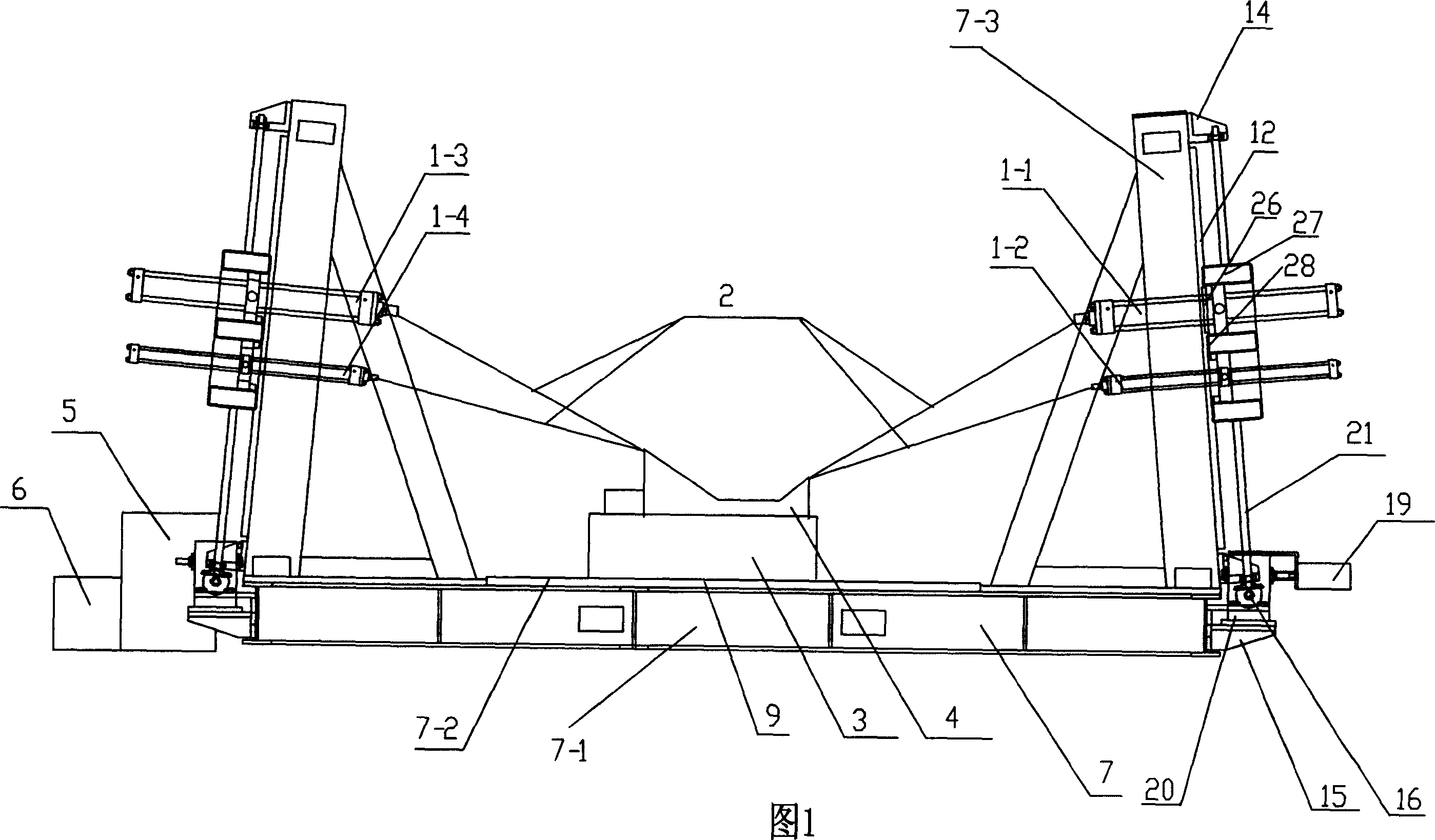

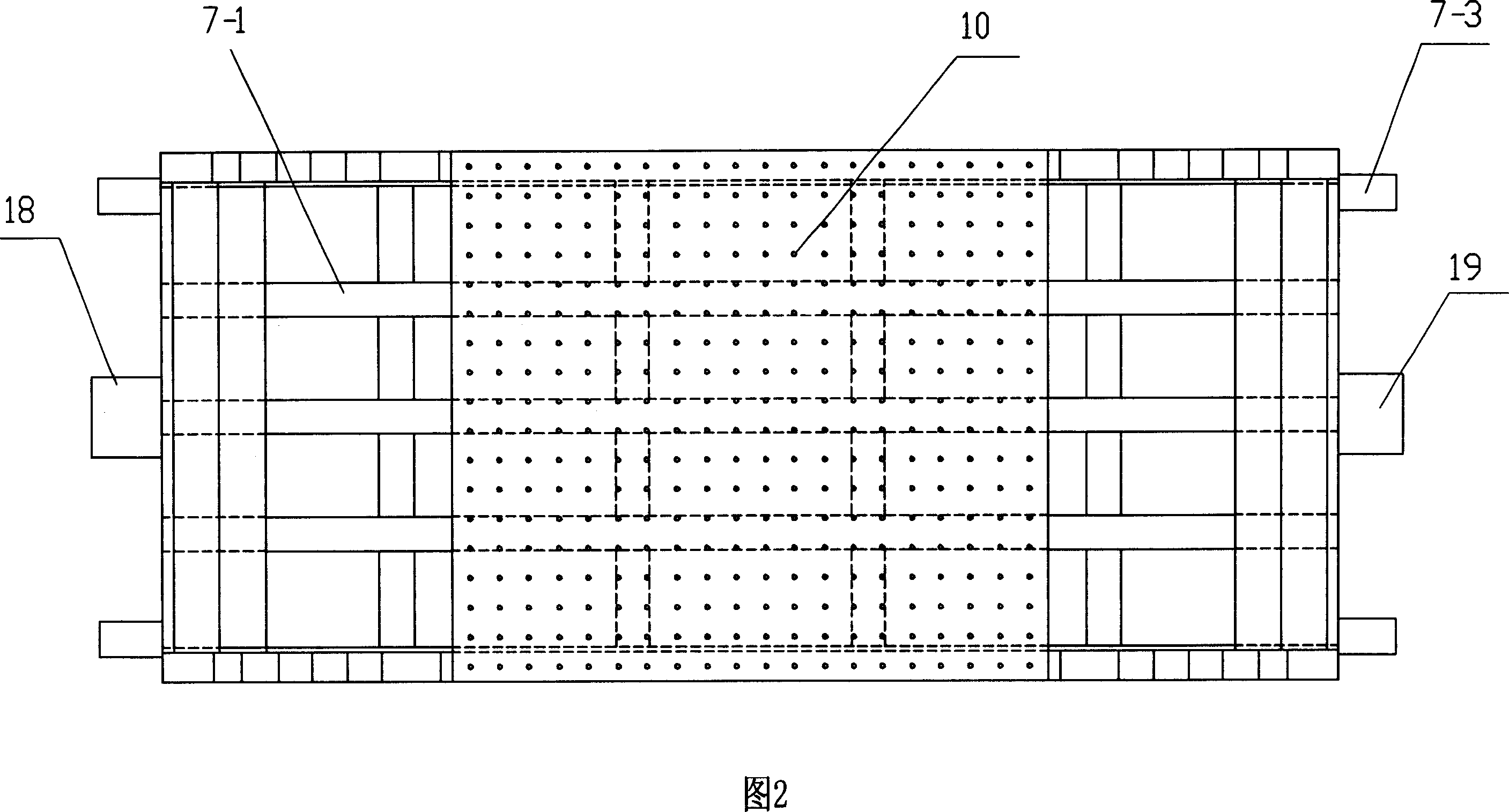

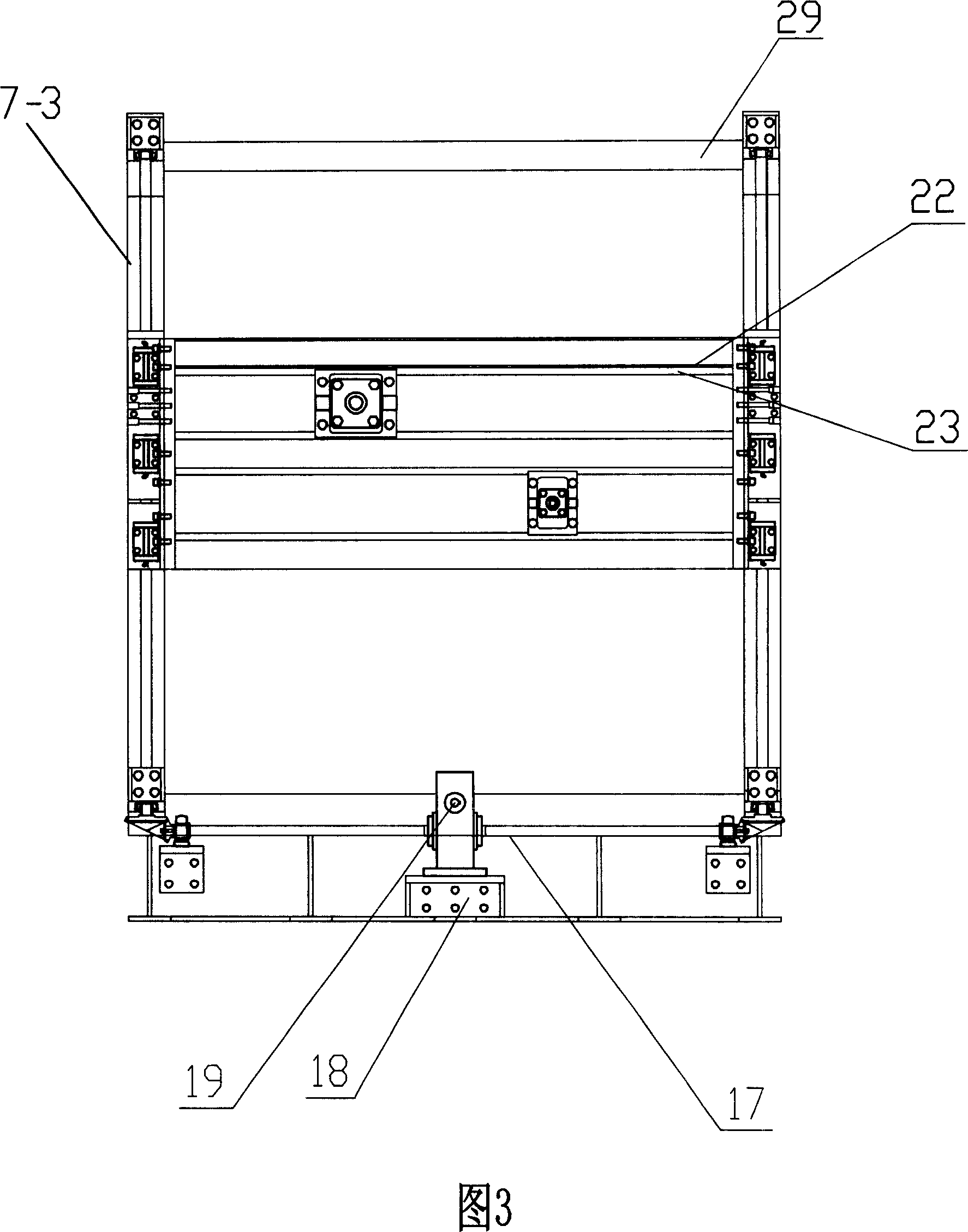

[0023] Referring to Figures 1 to 8, the car seat slide rail recliner strength testing machine according to the embodiment of the present invention is provided with a test oil cylinder 1, a test connection line 2, a fixture 3, an oil storage tank 6, a pressure oil pump 5, a frame 7, and a test oil cylinder The positioning component and the control computer, the test cylinder positioning component and the fixture 3 are installed on the frame 7, the test cylinder 1 is movably connected with the test cylinder positioning component, the product under test 4 is fixed on the fixture 3, the pressure oil pump 5 and the oil storage tank 6 are connected and used To provide test power, the test cylinder positioning component is used to test the positioning of the cylinder 1, the test cylinder 1 is connected to the oil storage tank 6, one end of the test connection line 2 is connected to the test cylinder 1, and the other end of the test connection line 2 is connected to the product under te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com