Centrifugal pressurizing propeller structure

A centrifugal, impeller technology, applied in non-variable-capacity pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve problems such as high cost, increased flow channel resistance, and reduced operating efficiency Achieve the effect of solving structural problems, reducing operating noise, and improving balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

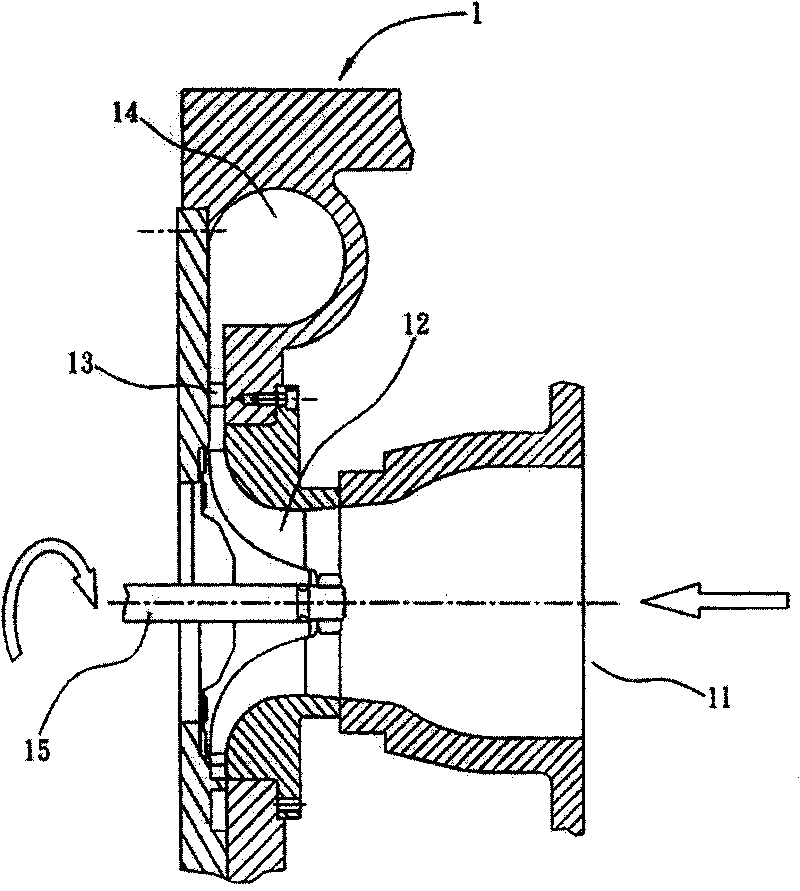

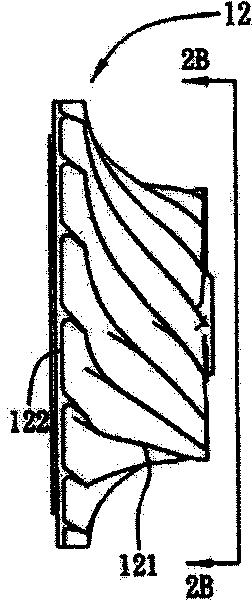

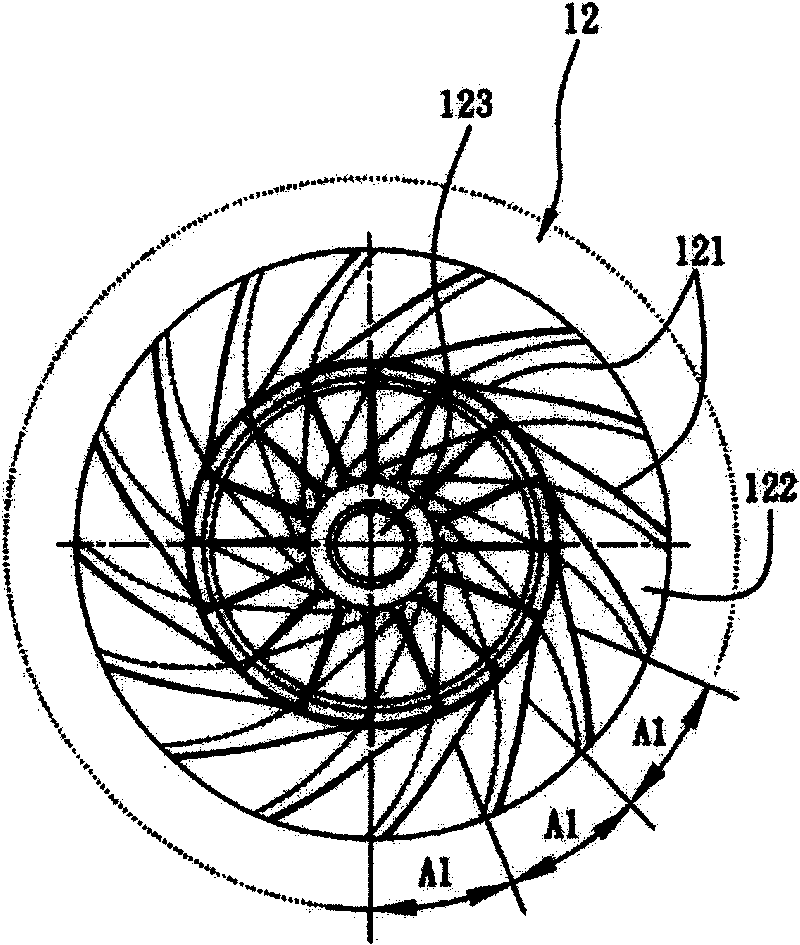

[0031] The centrifugal pressurized impeller structure 30 proposed by the present invention is applied to the above-mentioned existing centrifugal rotary pressurization device, and the impeller structure is as follows Figure 6A and Figure 6B As shown, the impeller structure includes an arc-shaped impeller body 31, which has a shaft hole 32 in the center of the body 31, and a wheel shaft 33 can pass through it and be perpendicular to the plane of the body 31; meanwhile, the present invention uses the circular The arc-conical body 31 is equally divided into multiple equal parts, and the embodiment 1 as shown in the figure is divided into two equal parts, and two groups of blade groups 35 are set, all have a plurality of blades 36 in the two groups of blade groups 35, to wrap around the The wheel shaft 33 is sequentially arranged around the wheel shaft 33; wherein, the adjacent blades 36 in each blade group 35 are arranged along the radial direction of the conical arc surface of...

Embodiment 2

[0036] Design of the present invention is except above-mentioned embodiment 1, also can change the number of vane group, just this body is equally divided into other quantities, as Figure 8 The shown embodiment 2 is that the main body 31 is divided into three equal parts, and three groups of blade groups 35 are designed, so that the interval angles between adjacent blades 36 differ by a fixed increasing angle α, and each blade group 35 The number of blades 36 and the corresponding interval angles are the same, that is, the blades 36 in the three groups of blades 35 are 120 degrees symmetrical to each other.

Embodiment 3

[0038] Figure 9 It is embodiment 3 of the present invention, it divides this body 31 into four equal parts, and designs four groups of vane groups 35, makes the spacing angle between adjacent vanes 36 differ by a fixed amplifying angle α respectively, and each vane The number of blades 36 in the group 35 and the corresponding interval angles are the same, that is, the blades 36 in the four groups of blade groups 35 are mutually symmetrical at 90 degrees.

[0039] Therefore, the number of blade sets 35 of the present invention is not limited, and the body 31 can also be divided into other numbers and the corresponding number of blade sets 35 is designed, only need to form a regular periodic change, unequal pitch blades 36 The impeller structure is sufficient; in addition, the interval angles of adjacent blades 36 in the same group of blade groups 35 do not necessarily need to differ by a fixed increase angle α, and can also be at any different interval angles respectively, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com