Vertical shaft wind power generator

A wind power generation device, vertical axis technology, applied in wind power generator components, electromechanical devices, wind power generation, etc., can solve the problems of lack of competitiveness for power generation, poor adaptability to wind speed changes, and constant power generation, etc., to achieve wind energy utilization High efficiency, strong adaptability, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

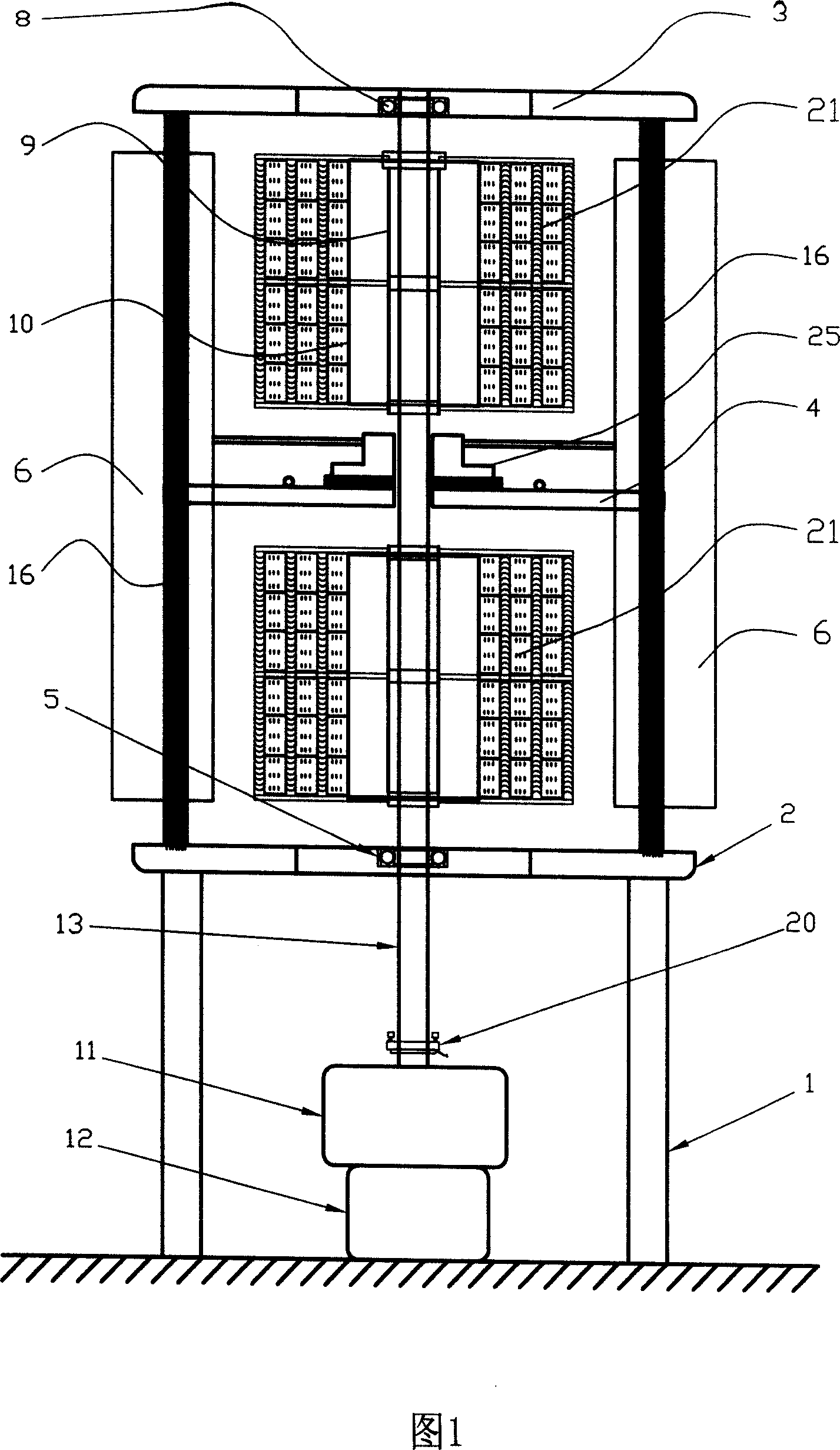

[0038] As shown in Figure 1, a vertical axis wind power generation device has: a vertically arranged rotating shaft 13, a wind wheel mechanism 21 installed on the rotating shaft 13, a support frame 1 for supporting the rotating shaft 13 and the wind wheel mechanism 21, The speed-increasing gear box 11 connected to the bottom of the rotating shaft 13 is connected to the generator 12 of the speed-increasing gear box 11, and it also includes an upper fixed plate 3, a middle fixed plate 4, a lower fixed plate 2, and 8 support columns 16, 8 Block wind deflector 6 and wind deflector guide 25, wherein,

[0039] The support frame 1 is fixedly installed on the ground or a building, the lower fixed plate 2 is fixedly connected to the support frame 1, the speed-increasing gear box 11 and the generator 12 are arranged under the support frame 1, and are fixedly installed on the support frame 1. on the ground or on buildings;

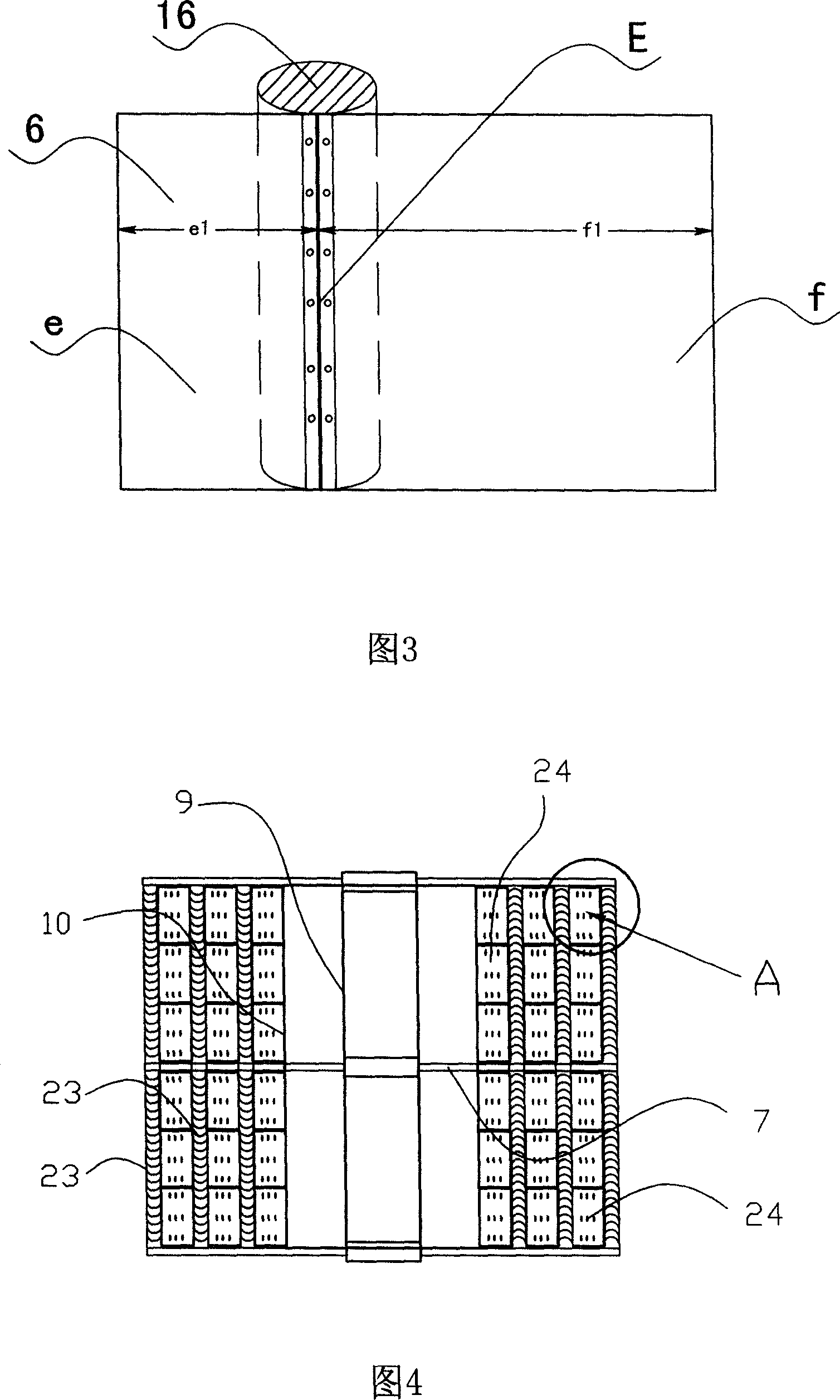

[0040] As shown in Figure 2, eight support columns 16 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com