Material for conductor tracks made of copper alloy

A technology of wire material and copper alloy, applied in metal material coating process, semiconductor/solid-state device manufacturing, semiconductor device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

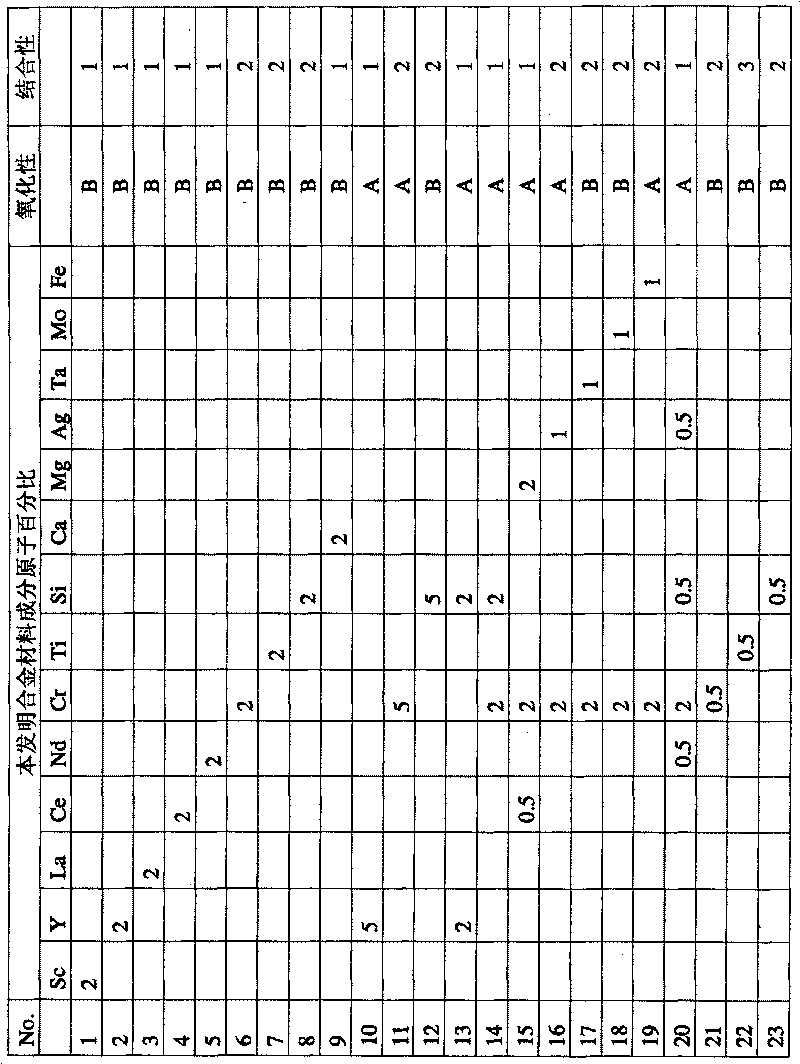

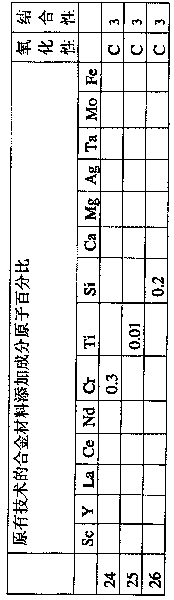

Examples

Embodiment Construction

[0012] Copper powder with a particle size of 130 microns was mixed with the respective alloy powders in a diffusion mixer. The mixed powder is introduced into a container made of unalloyed steel, degassed, and the container is evacuated and sealed in an airtight manner.

[0013] The thermal compression was carried out in a HIP apparatus at a temperature of 100° C. to 200° C. below the respective solidus lines constituting the copper alloy and a pressure of 2000 bar. In all alloy variants, the density is greater than 98% of theoretical and the grain size is less than 500 microns. 3D is 300x150x10mm 3 The sputtering target and 3D is 50x50x2mm 3 The oxidized samples were fabricated using a hot isostatic briquetting machine. Thereafter, each layer of 0.5 micron thickness is deposited on the glass substrate (liquid crystal display glass) by magnetron sputtering, and the adhesiveness of these layers is qualitatively measured and evaluated by tape test (1, bonding is significantly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com