Method for return repairing image sensing mould set and clamp therewith

An image sensing and module technology, used in image communication, color TV parts, TV system parts, etc. Improve efficiency and ensure the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

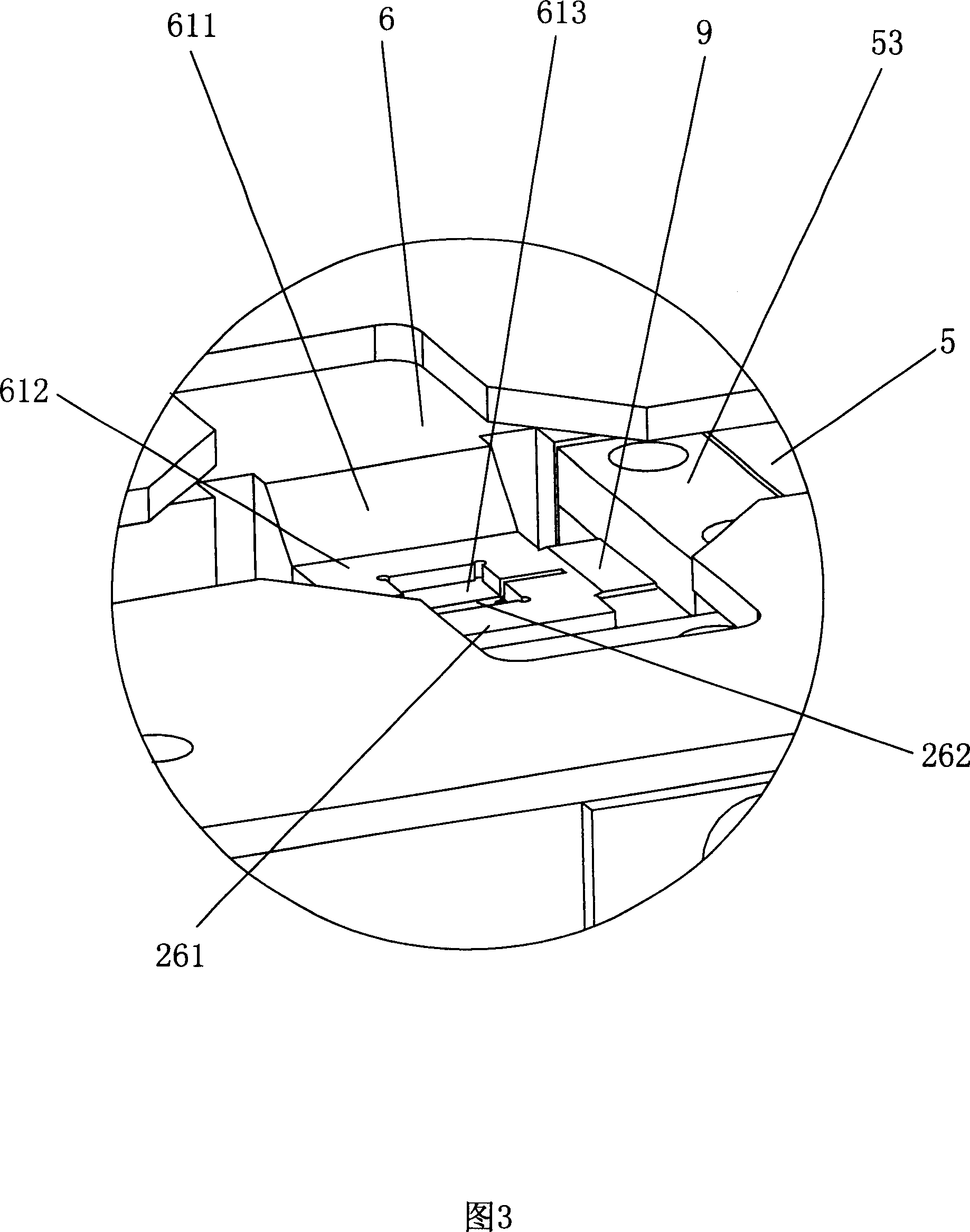

Embodiment approach 1

[0042] Implementation mode 1: In a tenth-level clean environment, prepare the camera module to be cleaned, use the adjusted image sensing module disassembly fixture, put the product into the disassembly fixture, and use the disassembly fixture to unpack the packaged camera module. The module is divided into two parts, one part is the lens module, the other part is the PCB board and the camera chip fixed on the PCB board, and then the edge part of the PCB board is fixed with a blowing fixture and the camera chip is exposed to the outside, and the vacuum ion is adjusted. Clean the air gun, blow and wash the photosensitive area of the wafer polluted by dust particles under a microscope (125x is suitable), check the cleanliness and appearance of the product after cleaning, and finally replace it with a good product lens module, stick it in the plastic disk After applying AB glue, the glued lens module is packaged on the purge jig, and after being baked in an oven at 75°C for 90 m...

Embodiment approach 2

[0043] Implementation mode 2: In a tenth-level clean environment, prepare a camera module with abnormal imaging, adjust the actual temperature of the reflow heating platform to 200°C, and place the ACF glue hot-press welding part of the product to be repaired on the heating platform covered with thermally conductive silicone skin Put it on (the role of the heat-conducting silicone skin is to make the product evenly heated), place it for 10 seconds, the ACF glue part of the product has been heated and softened, take it off immediately, gently pull the two solders (ie FPC and PCB board), and then use ACF The remover cleans the residual glue on the PCB board or FPC pad, and then re-presses the FPC and PCB board on the pressure welding machine, and then conducts the camera function test to check the camera effect after repair, so as to achieve the secondary quality of the material. The effect of using.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com