Driving device for a processing machine

A driving mechanism, processing machine technology, applied in printing presses, rotary printing presses, general parts of printing machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

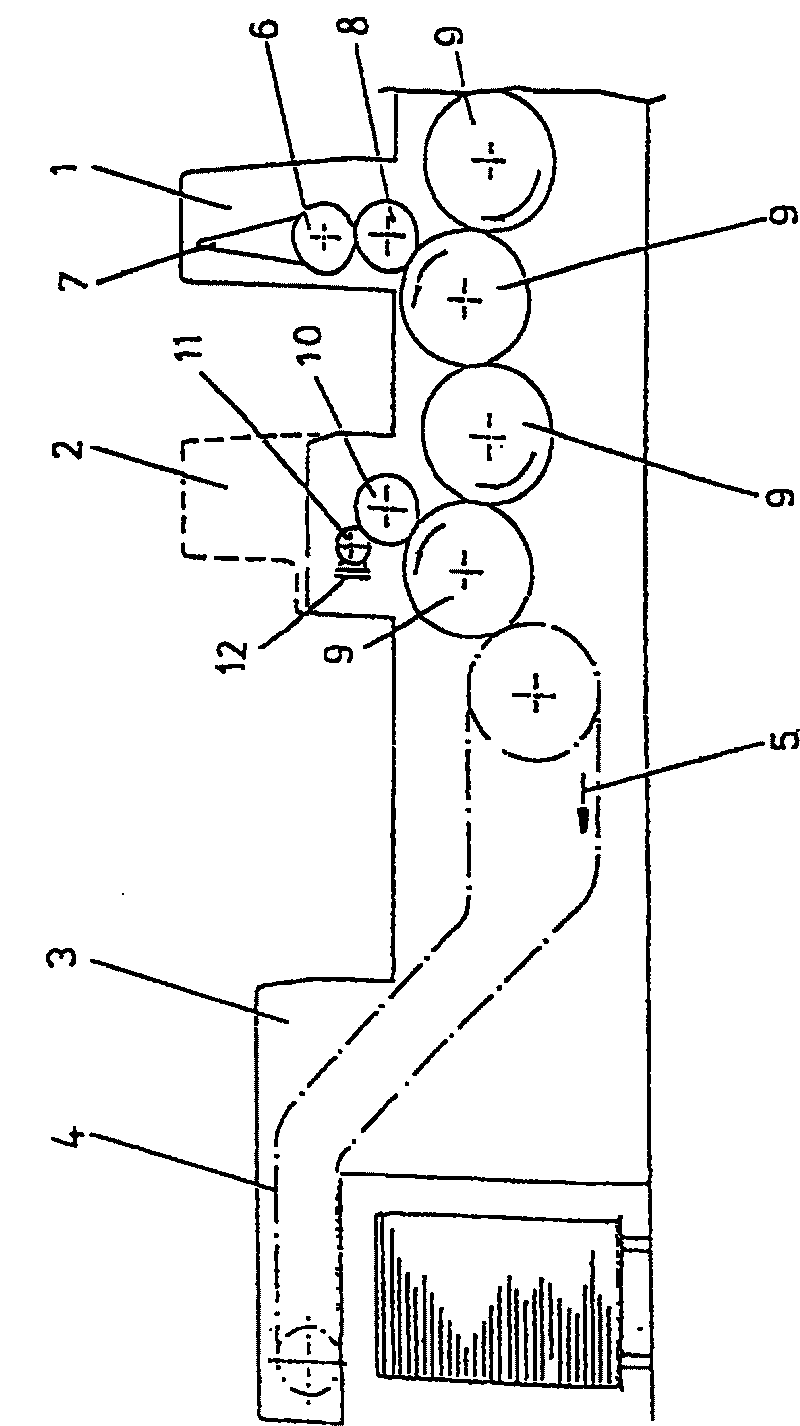

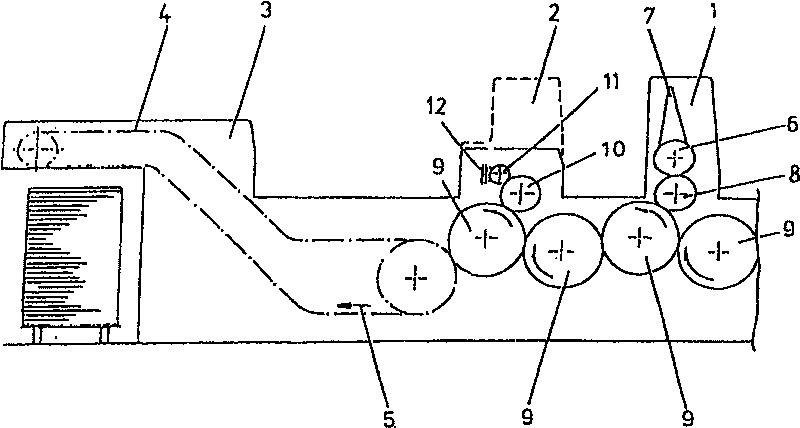

[0025] exist figure 1 The sheet-fed web printing press shown in includes at least one printing unit 1 , which is formed as an offset printing unit in a known manner from a plate cylinder 6 with associated inking unit 7 and a blanket cylinder 8 . A dampening unit is optionally assigned to the plate cylinder 6 upstream of the inking unit 7 in its direction of rotation. The sheet-fed web printing press also has at least one varnishing unit or flexographic printing unit 2 , which consists of a plate cylinder 10 and a metering system 11 , 12 . In this embodiment, the dosing system 11, 12 comprises, as is well known, a grid-configured inking roller 11 and a chamber doctor blade system 12 for processing paint, alternatively flexographic ink.

[0026] For conveying the printing material in the form of a printed sheet in the conveying direction 5 , a plurality of conveying cylinders 9 are provided, here a printed sheet guide cylinder with a gripper system. The varnishing unit / flexogr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com