Microwave sulfur lamp

A sulfur lamp and microwave technology, applied in the field of microwave sulfur lamps, can solve the problems of easy damage to the inner surface of the waveguide 3, trouble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

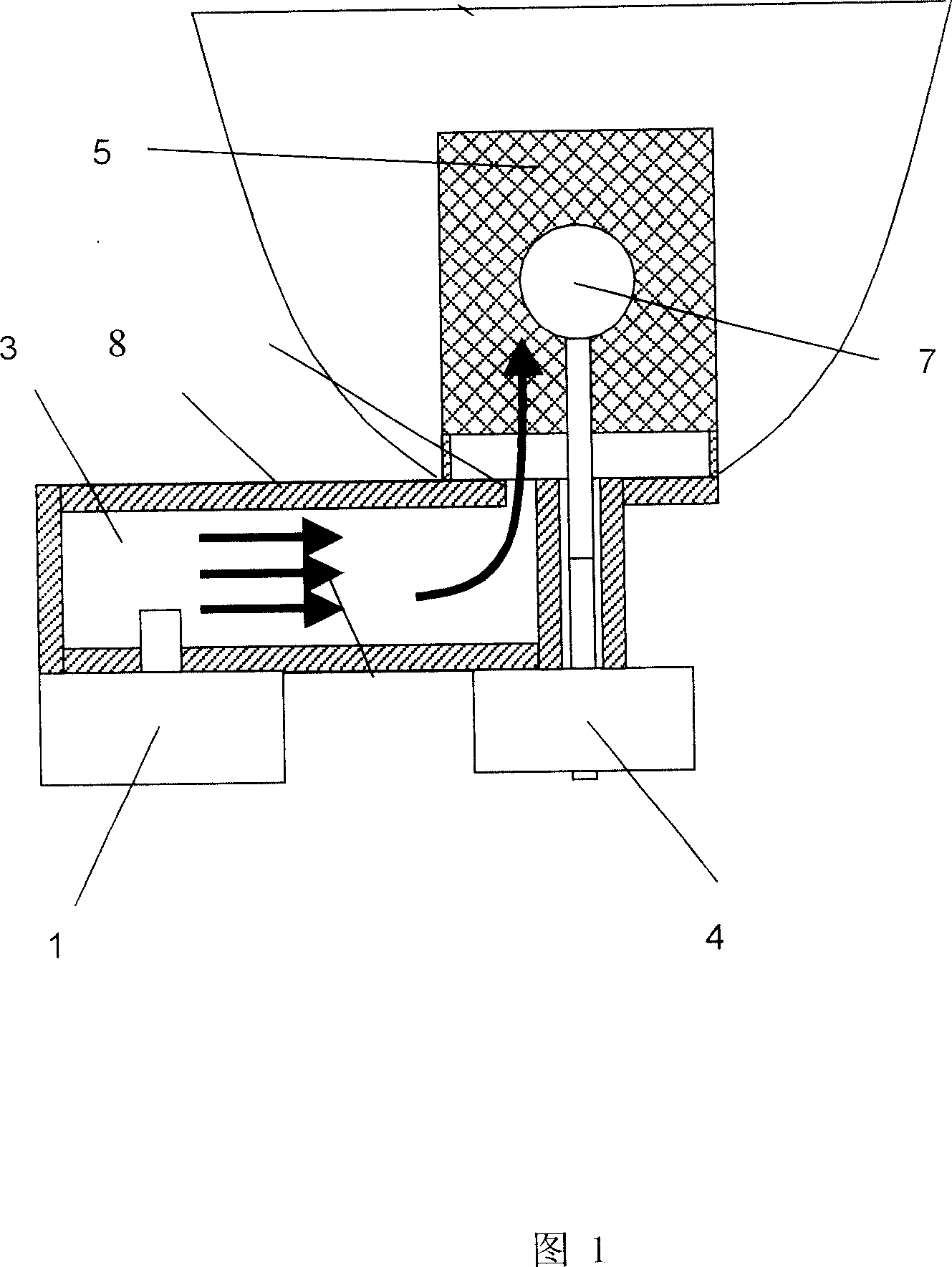

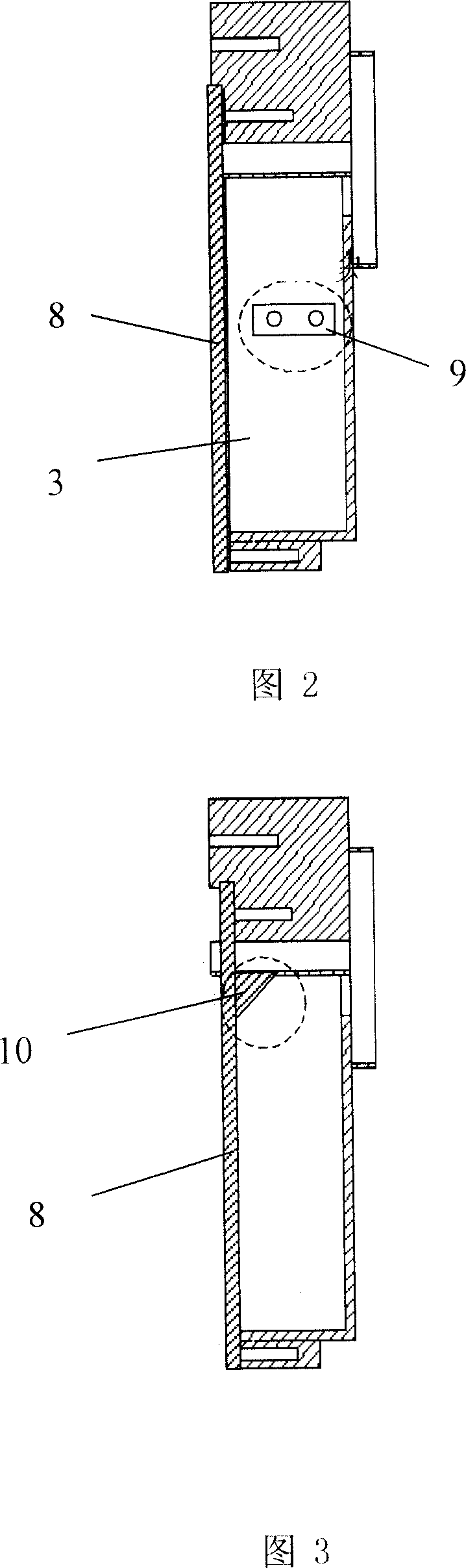

[0018] The microwave sulfur lamp of the present invention will be described with reference to the accompanying drawings and examples.

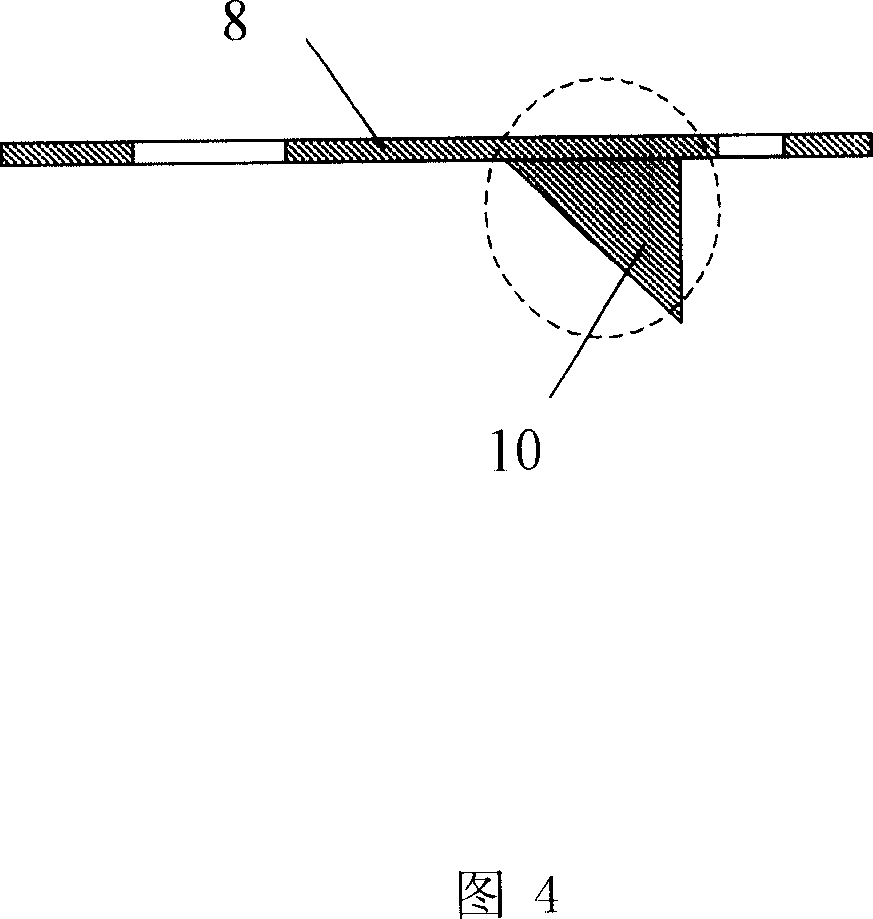

[0019] The structure of the microwave sulfur lamp of the present invention includes a waveguide cavity consisting of a cover plate, a waveguide cavity body, and a blending block. The blending block 10 is arranged on one side end of the inner cavity cover plate 8 forming the waveguide cavity. The mixing block 10 is integrated with the cover plate 8 and is made into a triangular prism.

[0020] The structure of the microwave sulfur lamp is mainly an improvement on the structure of the original waveguide cavity. After the deployment block 10 is made into a triangular rod shape, it is welded or bonded with the new cover plate 8, and the cover plate 8 and the triangular column deployment block 10 are made into a One. This one-piece part can be produced in large quantities by direct casting method, which is convenient for installation.

[0021] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com