Capacitor microphone assembly

A technology of condenser microphone and electro-acoustic transducer, applied in electrostatic transducer microphone, electret electrostatic transducer and other directions, can solve problems such as poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

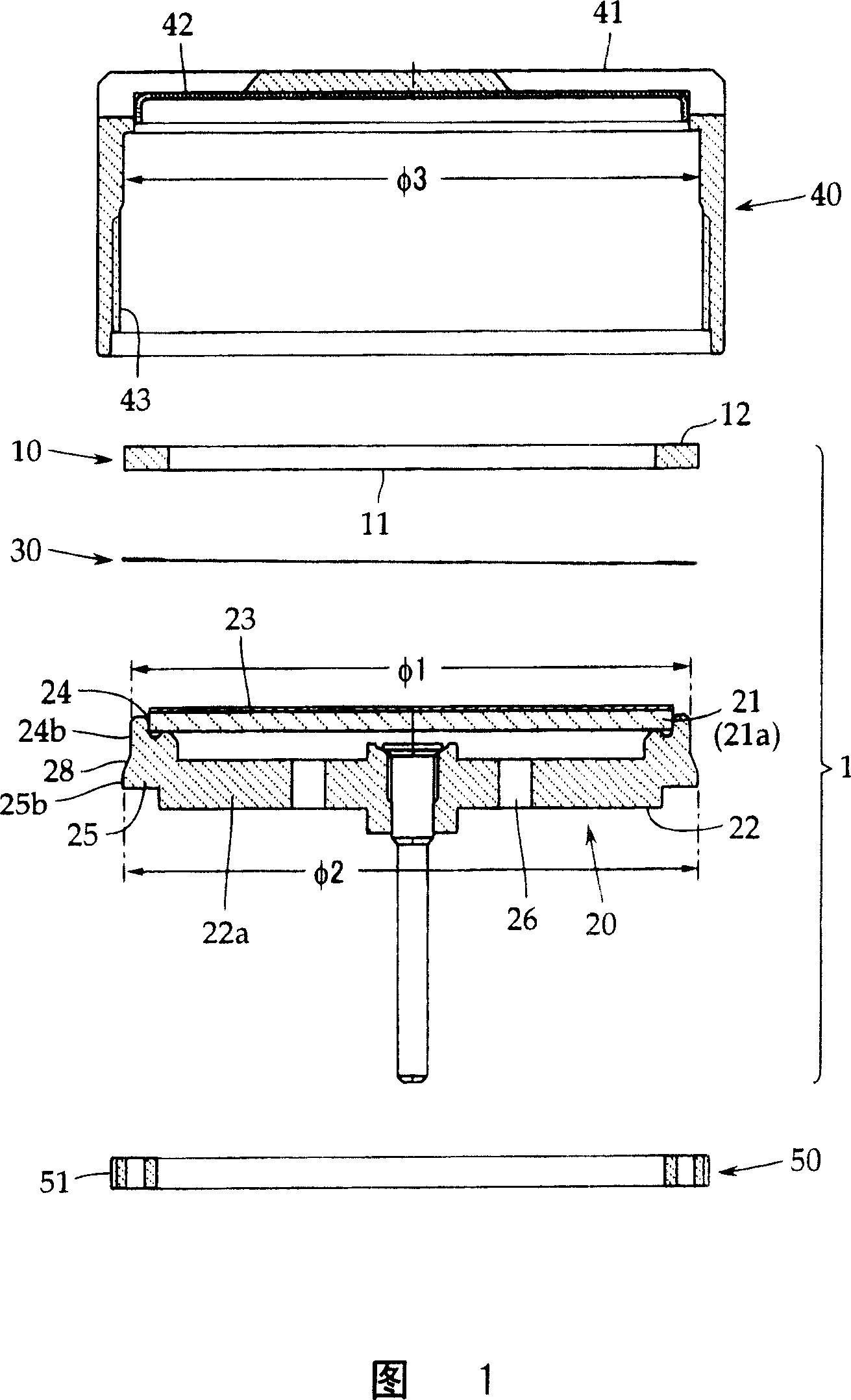

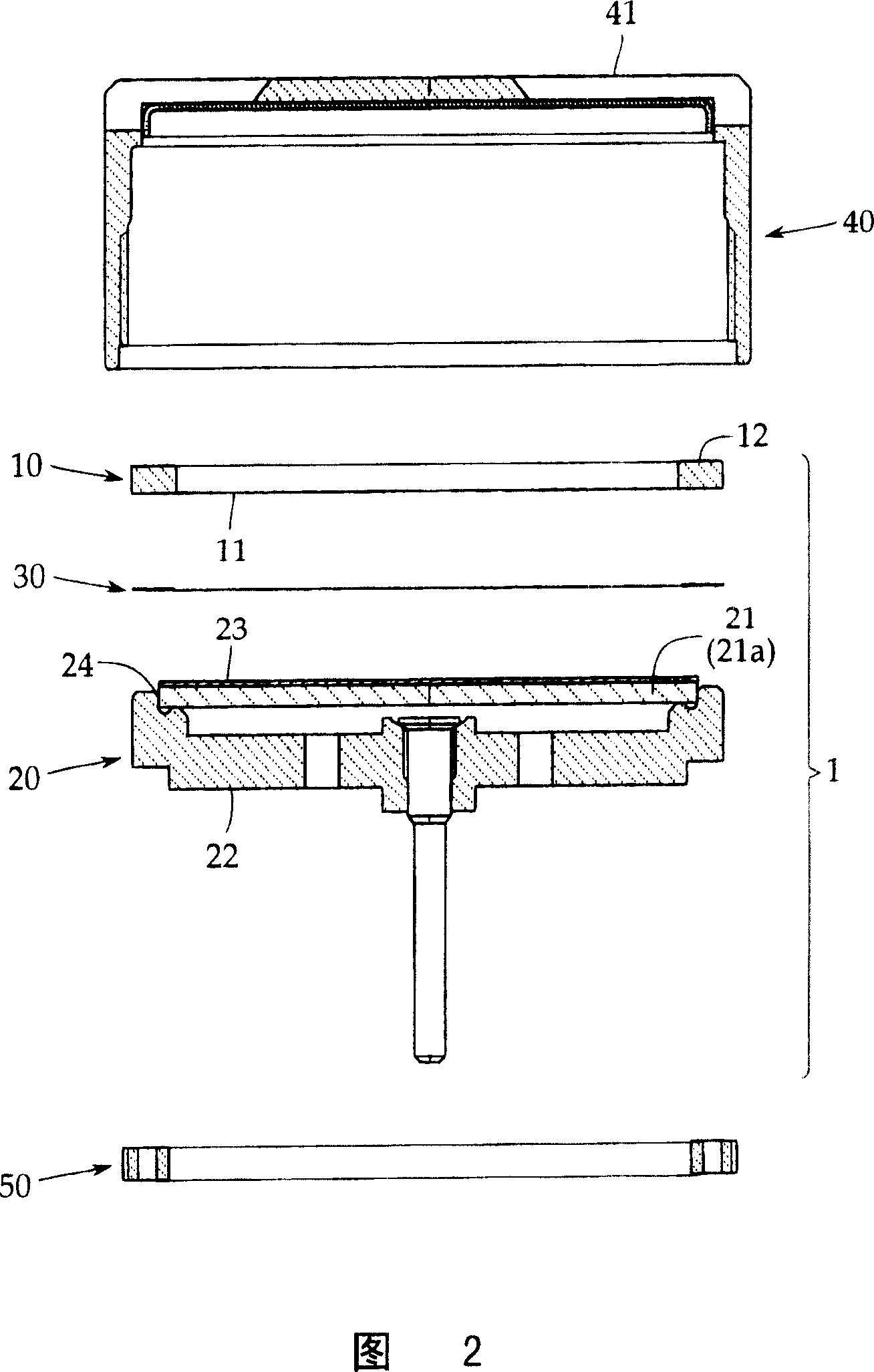

[0026] Hereinafter, an embodiment of the present invention will be described using FIG. 1 , but the present invention is not limited thereto. Fig. 1 is an exploded sectional view showing an embodiment of a condenser microphone unit of the present invention. In addition, the same reference numerals are used for components that do not need to be changed from the conventional example described above in FIG. 2 .

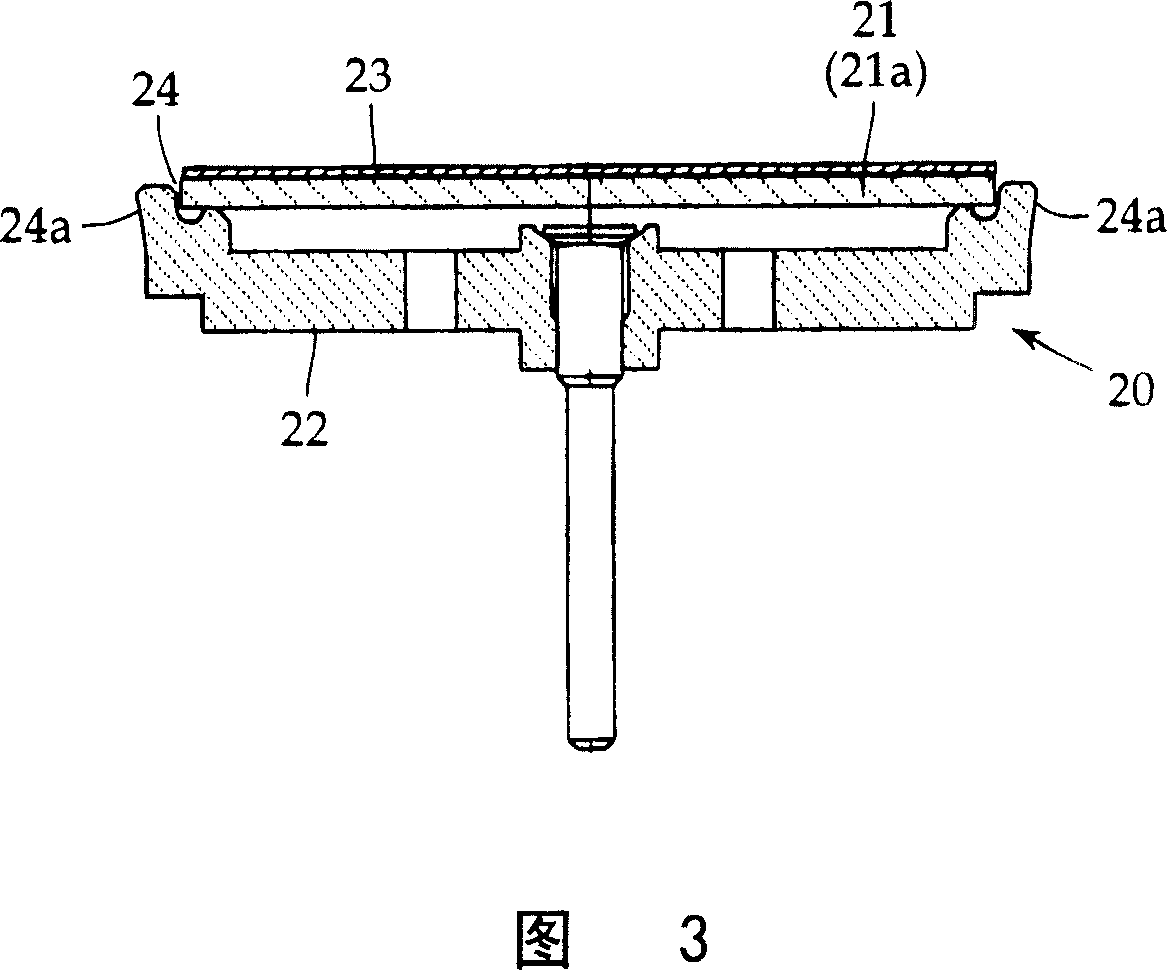

[0027] As shown in FIG. 1 , this condenser microphone unit includes, as a basic configuration, an electroacoustic transducer 1 including a diaphragm assembly 10, a fixed pole assembly 20, and an electrically insulating spacer 30 disposed therebetween. ; the assembly case 40 for the electroacoustic transducer 1 ; the locking ring 50 as a fastening and fixing mechanism for fastening and fixing the electroacoustic transducer 1 in the assembly case 40 . In addition, the condenser microphone unit in this example is a back-electret type in which the fixed pole is formed of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com