Plasma display device and its driving method

A plasma and display device technology, applied in the direction of identification devices, static indicators, instruments, etc., can solve the problems of wall charge loss, increased recombination ratio, and inability to display images, etc., and achieve the effect of preventing misdischarge and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] In the following, preferred embodiments are given, and the plasma display device and its driving method in the present invention will be described in detail with reference to the accompanying drawings.

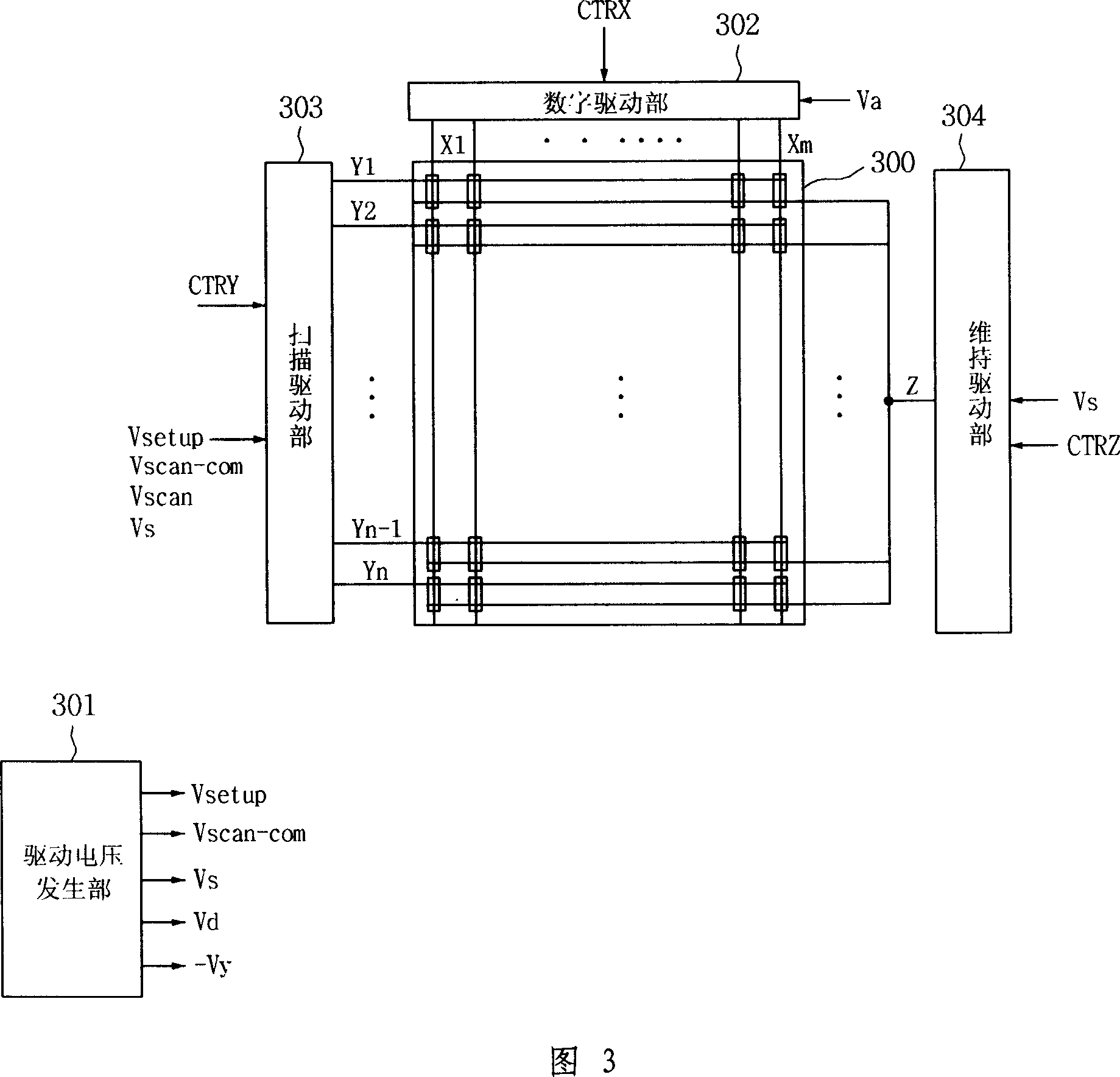

[0095] FIG. 3 is a schematic structural diagram of a plasma display device in the present invention.

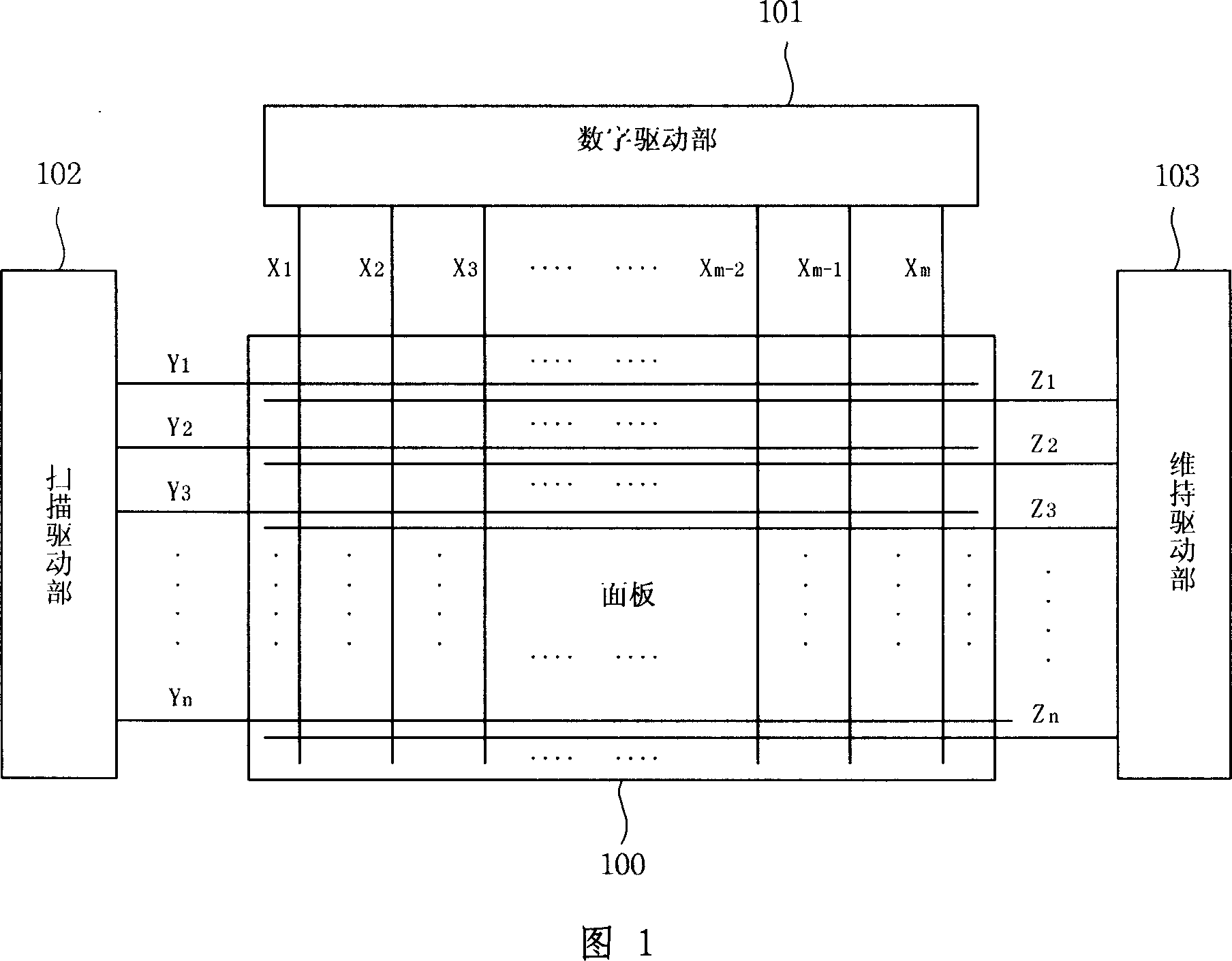

[0096] As shown in FIG. 3 , the plasma display device of the present invention includes scan electrodes ( Y1 to Yn ) and sustain electrodes Z, and a plurality of digital electrodes ( X1 to Xm ) intersecting the scan electrodes and sustain electrodes Z.

[0097] In addition, it includes: during the reset period, the positioning period and the maintenance period, the plasma display panel 300 that negatively applies the driving pulse to the digital electrodes (X1 to Xm), the scan electrodes (Y1 to Yn) and the sustain electrode Z; The digital electrode (X1 to Xm) formed on 300 provides the digital driving part 302 of data; the scanning driving part 303 driving the scanning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com