Vortex type compressor

A scroll compressor, compression chamber technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problems of further improvement of efficiency, breathing loss, compression loss, etc., to achieve the highest compression efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

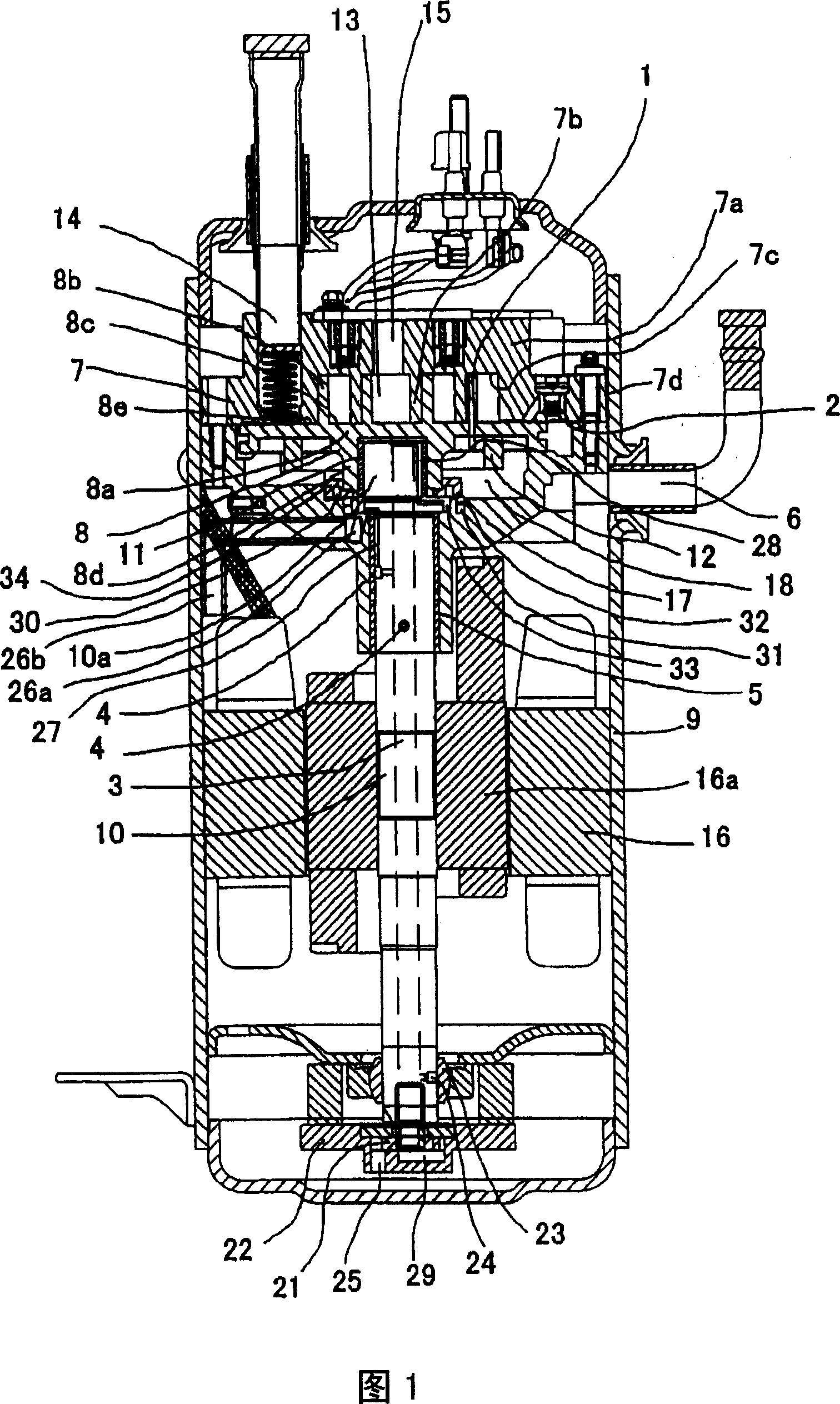

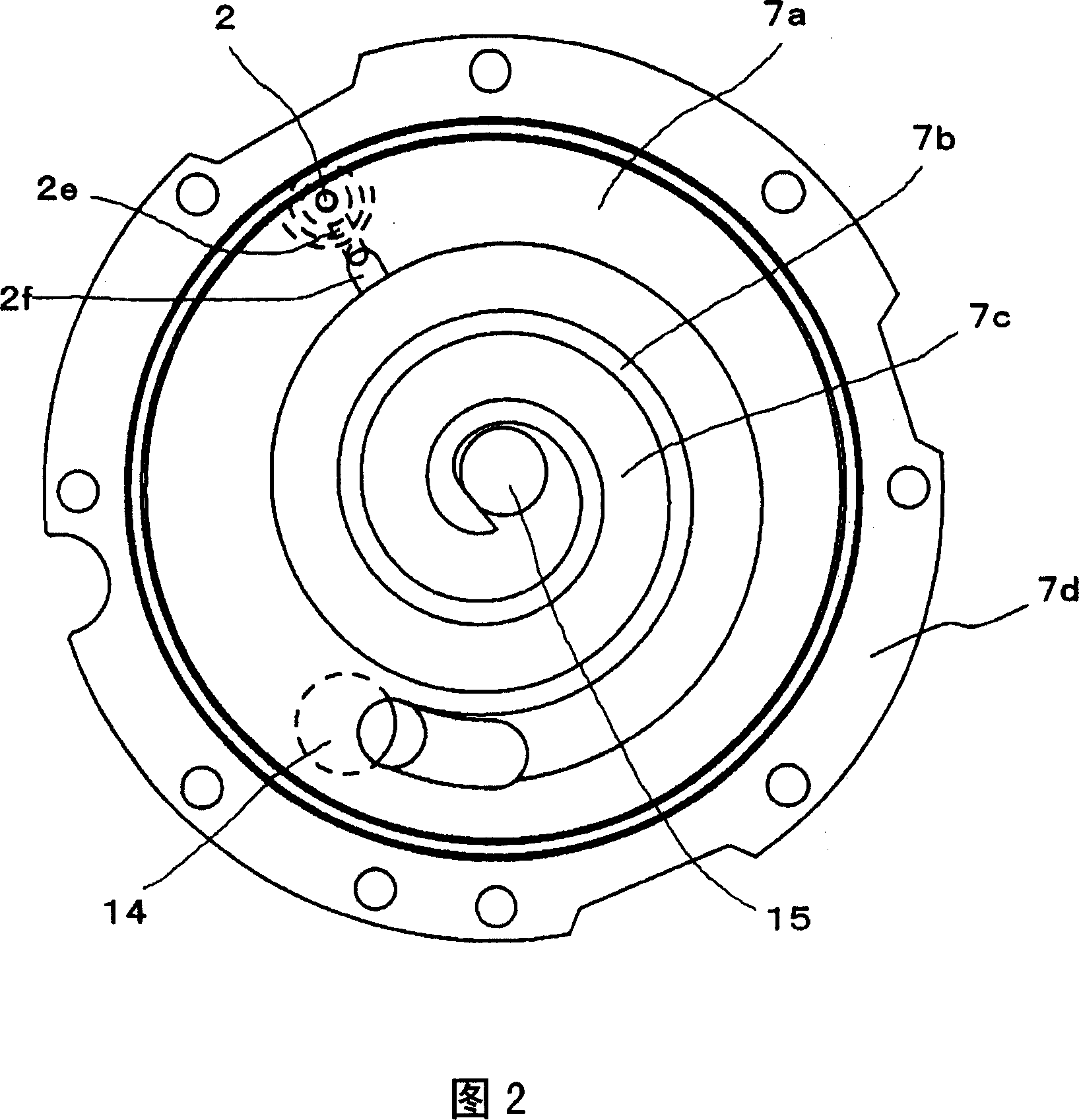

[0030] Next, the scroll compressor of the present invention will be described in detail based on the illustrated embodiments. Here, at first, Fig. 1 is a sectional view of an embodiment of the present invention, in this figure, firstly, 7 is a fixed scroll, as detailed in Fig. The roll sheet 7b erected on one side of the cover plate 7a and the support portion 7d formed in a cylindrical shape around the roll sheet 7b on the outer peripheral side of the cover plate 7a are constituted, and the roll sheet 7b of the cover plate 7a is erected. The face constitutes the dedendum 7c. Here, FIG. 2 shows the state of the fixed scroll 7 seen from the lower side of FIG. 1 .

[0031] Moreover, the support portion 7d is mounted on the frame 17 by screws or the like, and the frame 17 is mounted on the substantially cylindrical casing 9 by a fixing method such as welding, whereby the fixed scroll 7 is held in the casing. 9 in the specified position.

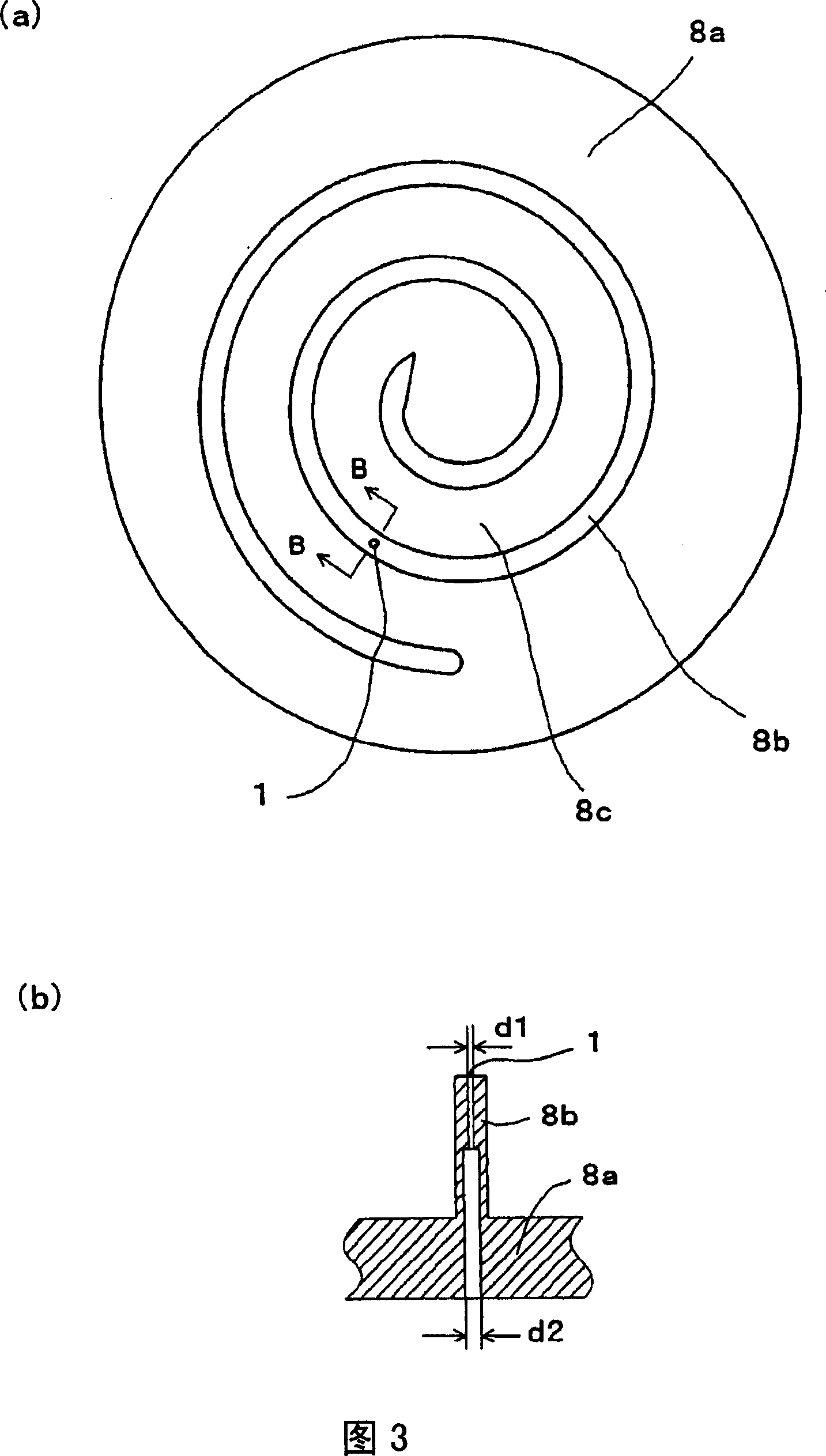

[0032] On the other hand, 8 is an orbit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com