Buoyancy scanning type polyphase liquid-level interface detection method and detector therefor

A detection method and a scanning technology, which is applied in the direction of buoy liquid level indicator, liquid level indicator, liquid/fluid solid measurement, etc., can solve the problems of unusable liquid level detection, radiation hazard, sinking to the bottom of the liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

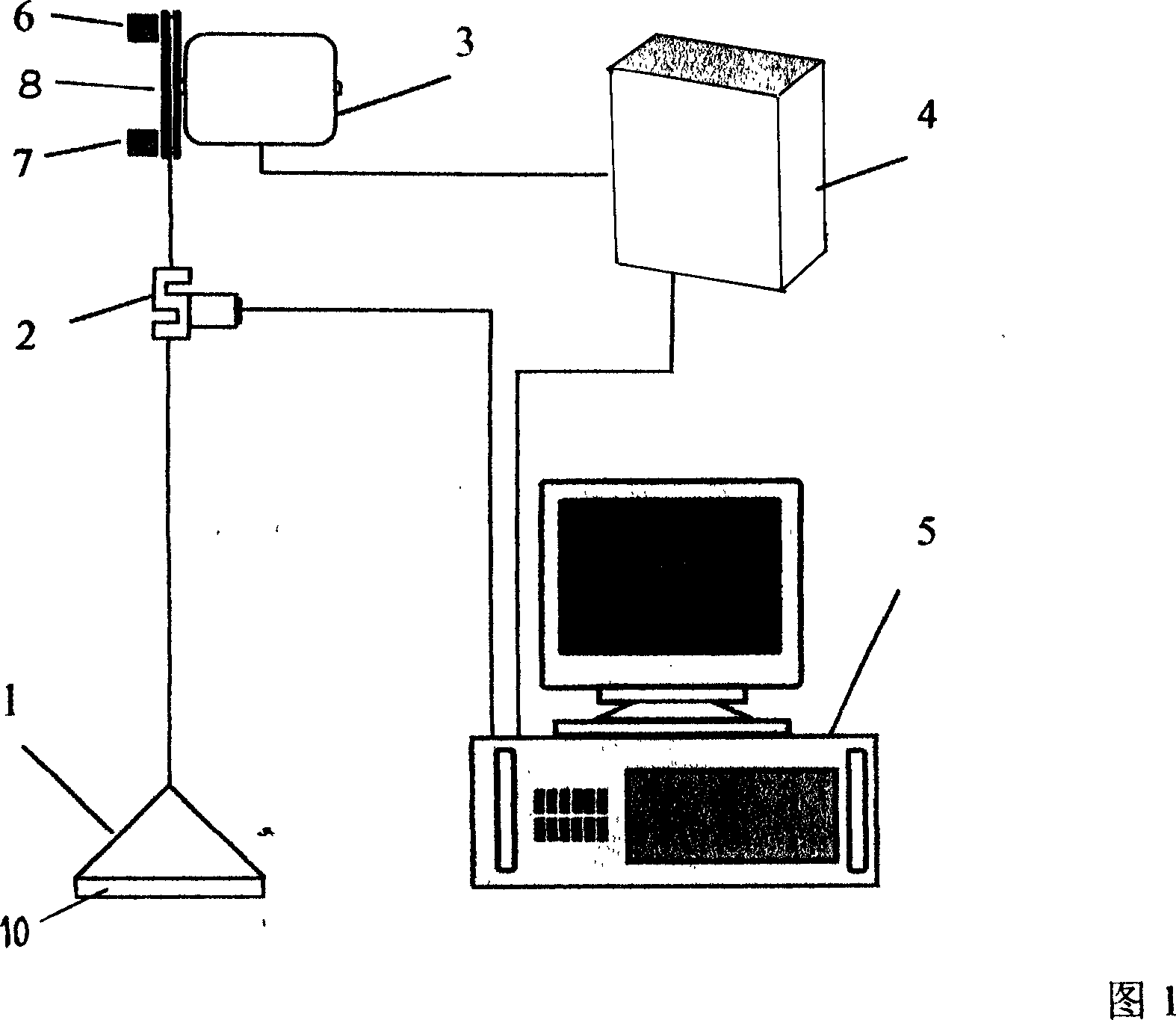

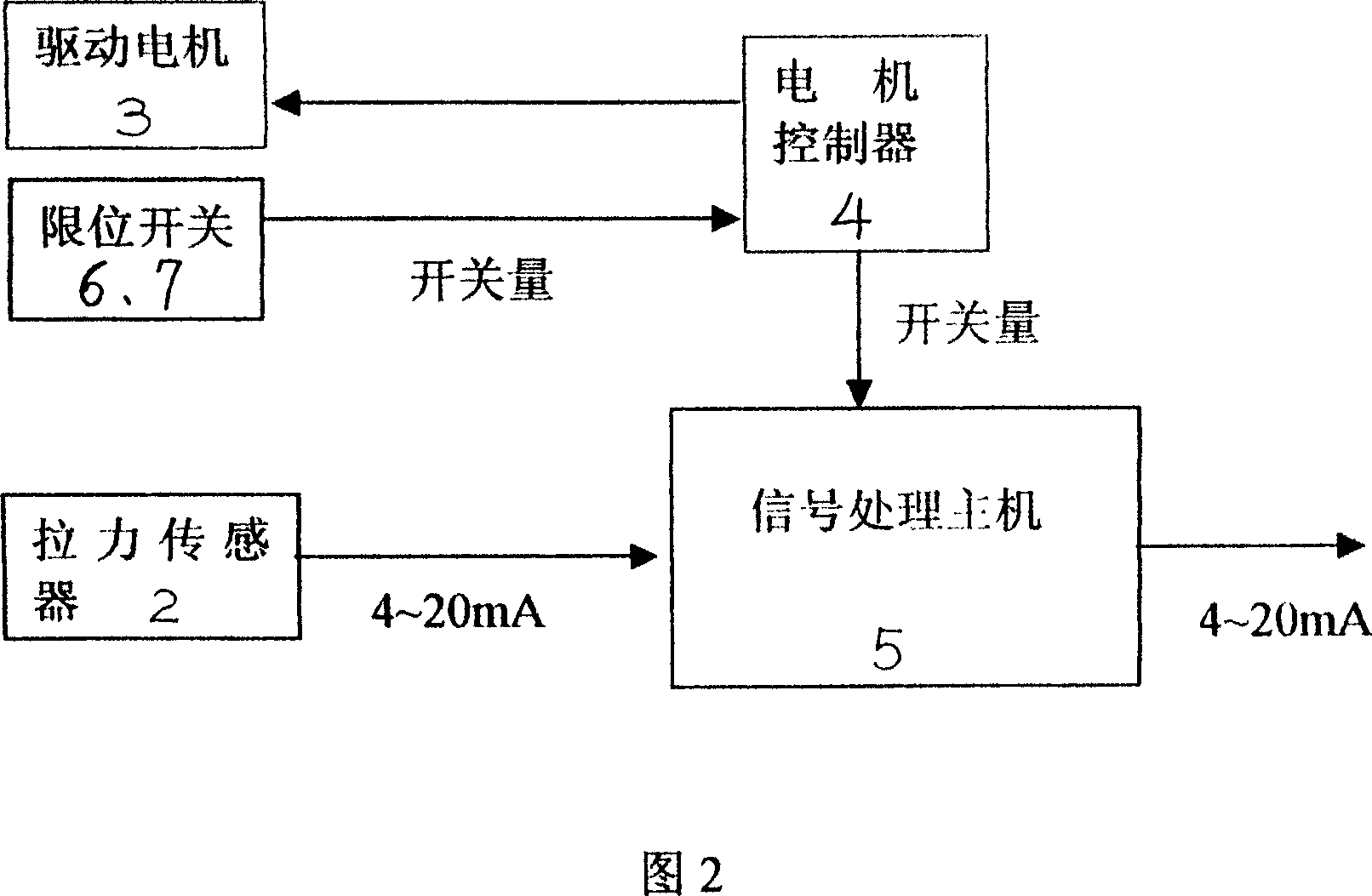

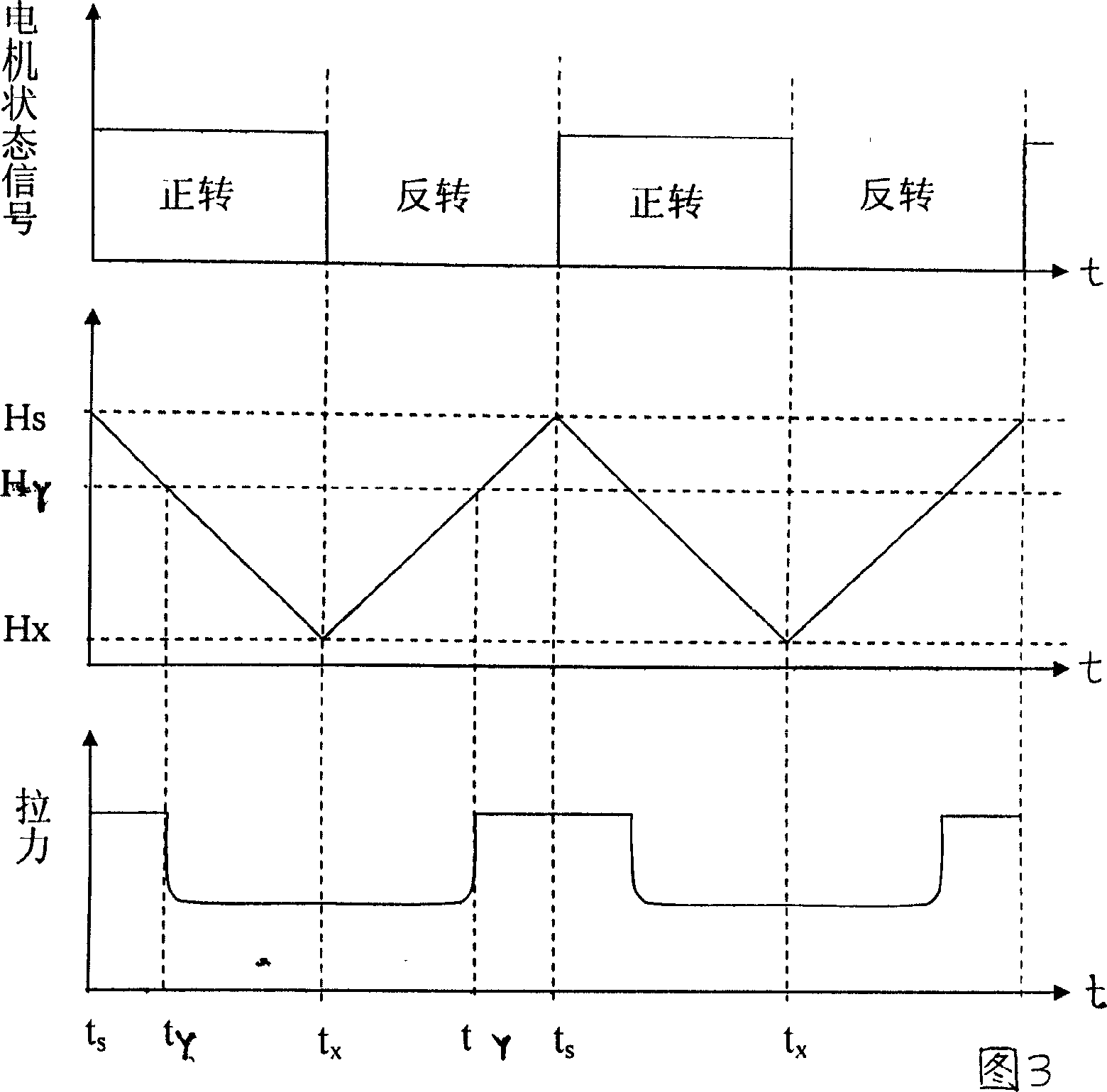

[0022] The buoyancy scanning multiphase liquid level interface detection method of the present invention will be described in detail below in combination with the structural content of the detector for implementing the method. As shown in Figure 1, the buoyancy scanning multiphase liquid level interface detector includes a signal processing host 5, a driving motor 3, a motor controller 4, a float 1, and a series connected to the pulling wire of the driving motor pulling the float 1 In the tension sensor 2, the bottom surface of the float 1 is a plane, and its overall average density is greater than the density of the liquid to be measured, and the optimum ratio of the two densities is 2:1. In this implementation structure, the upper part of the float 1 is a cone, so as to avoid depositing dirt on the float to change its quality, to keep the weight and density of the float as constant as possible, and to avoid measurement errors; The plane bottom surface of the circular cake bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com