Paging element of printer

A technology for printers and components, applied in pile separation, object separation, thin material processing, etc., can solve the problems of unfavorable economic benefits of production operations, high purchase cost, and increased tediousness of the production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

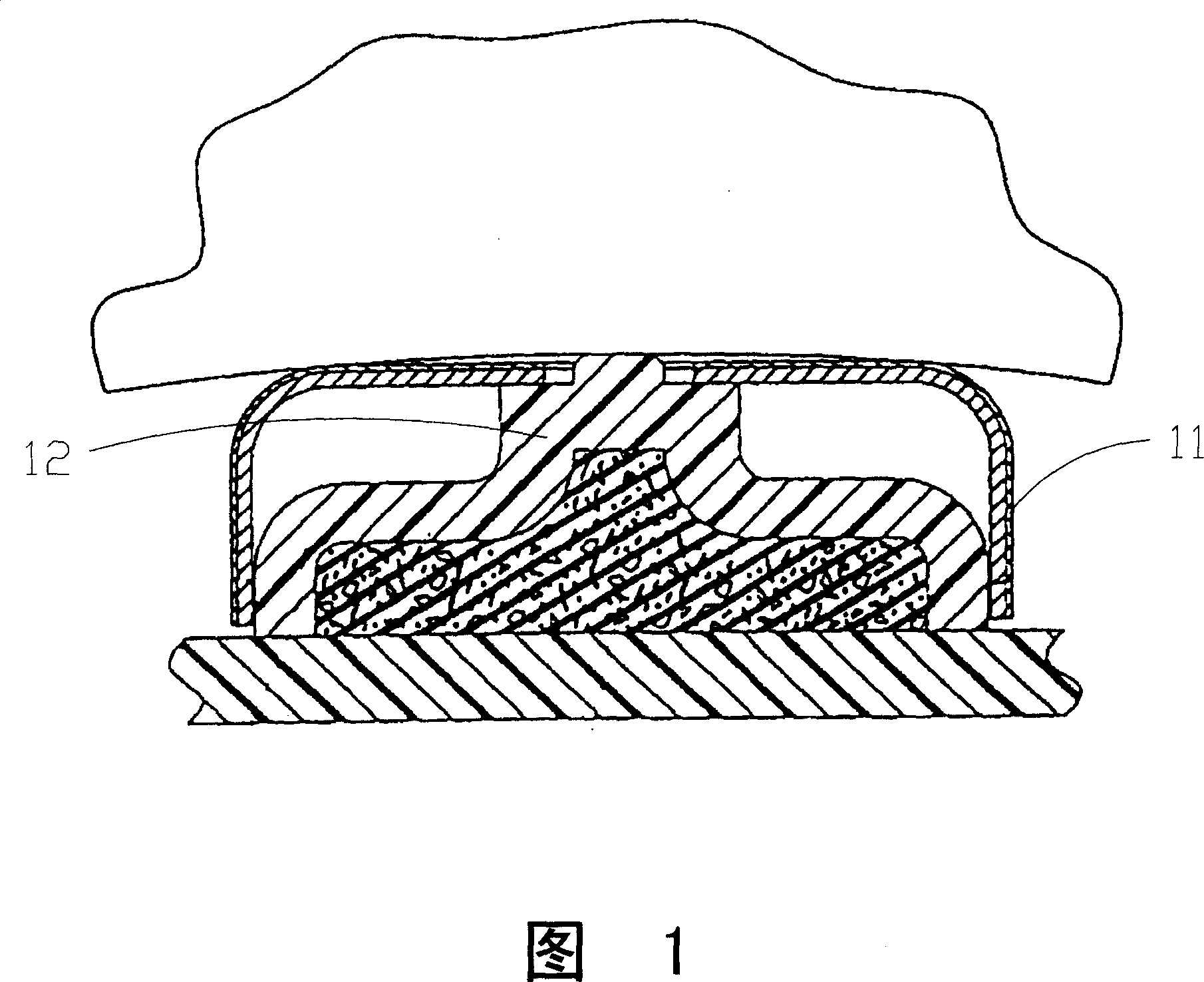

[0021] The invention relates to a paging component of a printer, which is mainly made of a single material and integrally formed. Although the paging element of the printer is made of a single material, it has two surfaces with different structures. Using the special design of the surface shape, various papers with different characteristics such as hardness, thickness and friction coefficient can be guided. The purpose of definite paging before sending to the printer, so as to avoid double or multi-feeding.

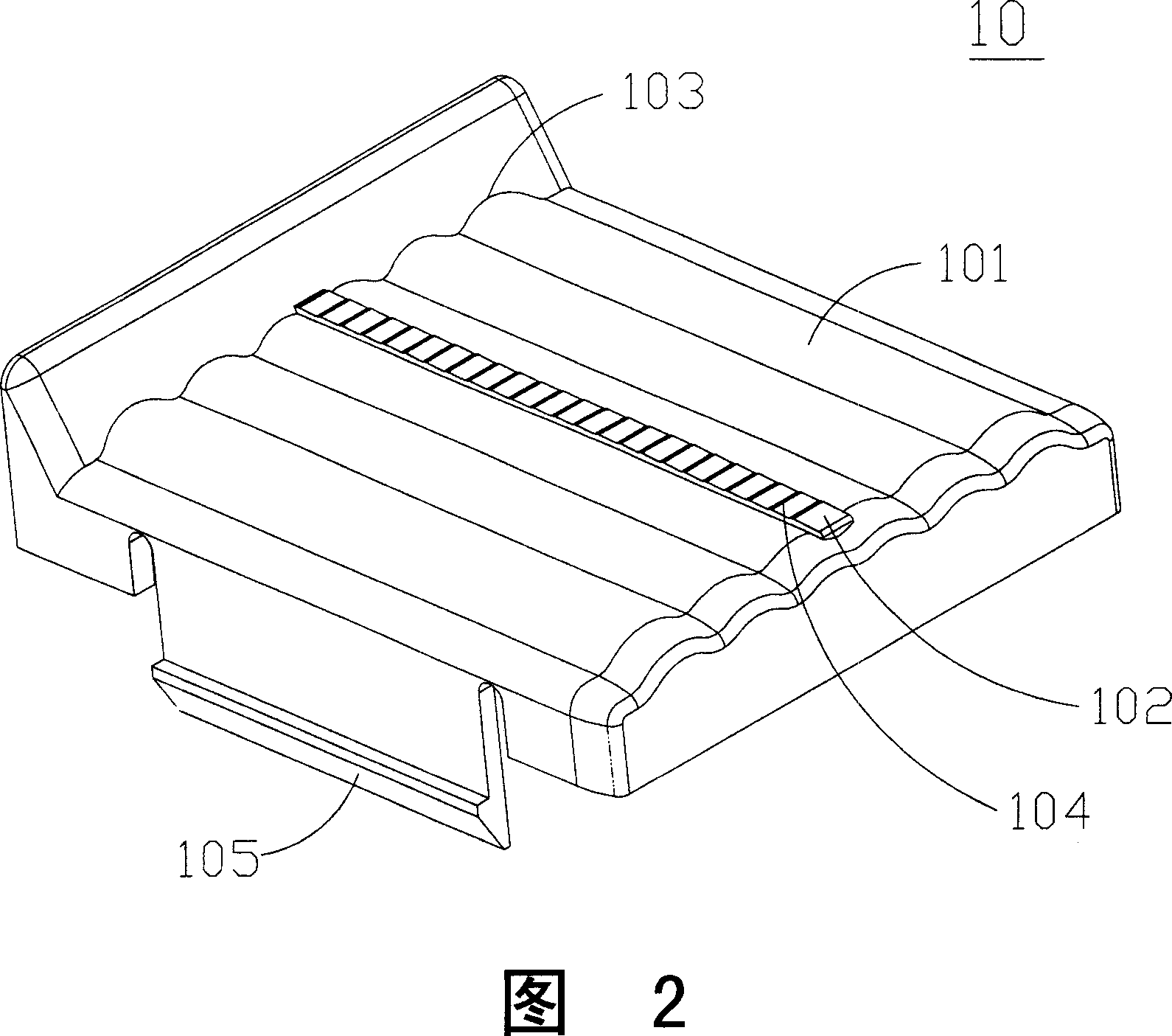

[0022] Please refer to FIG. 2 , which is a schematic diagram of a preferred embodiment of the paging component of the printer of the present invention. As shown in the figure, the page sorting element 10 of the printer of the present invention is integrally formed from materials with the same material coefficient to form two surfaces with different structures, wherein the two surfaces include a first surface 101 and a second surface 102, wherein the first surface 101 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com