Disk brake with a spring arrangement

A disc brake, spring device technology, applied in the direction of brake type, brake components, mechanical equipment, etc., can solve problems such as disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

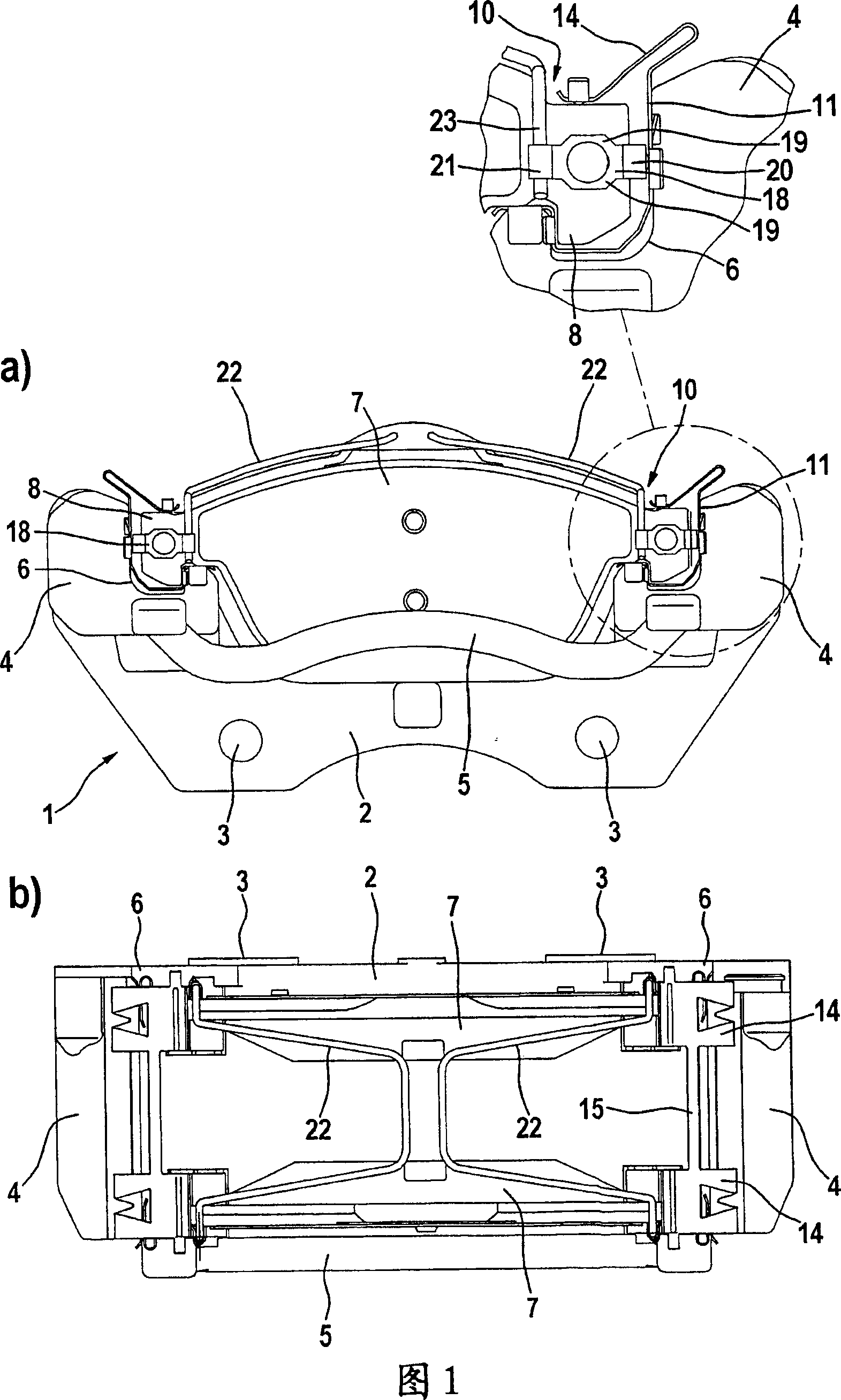

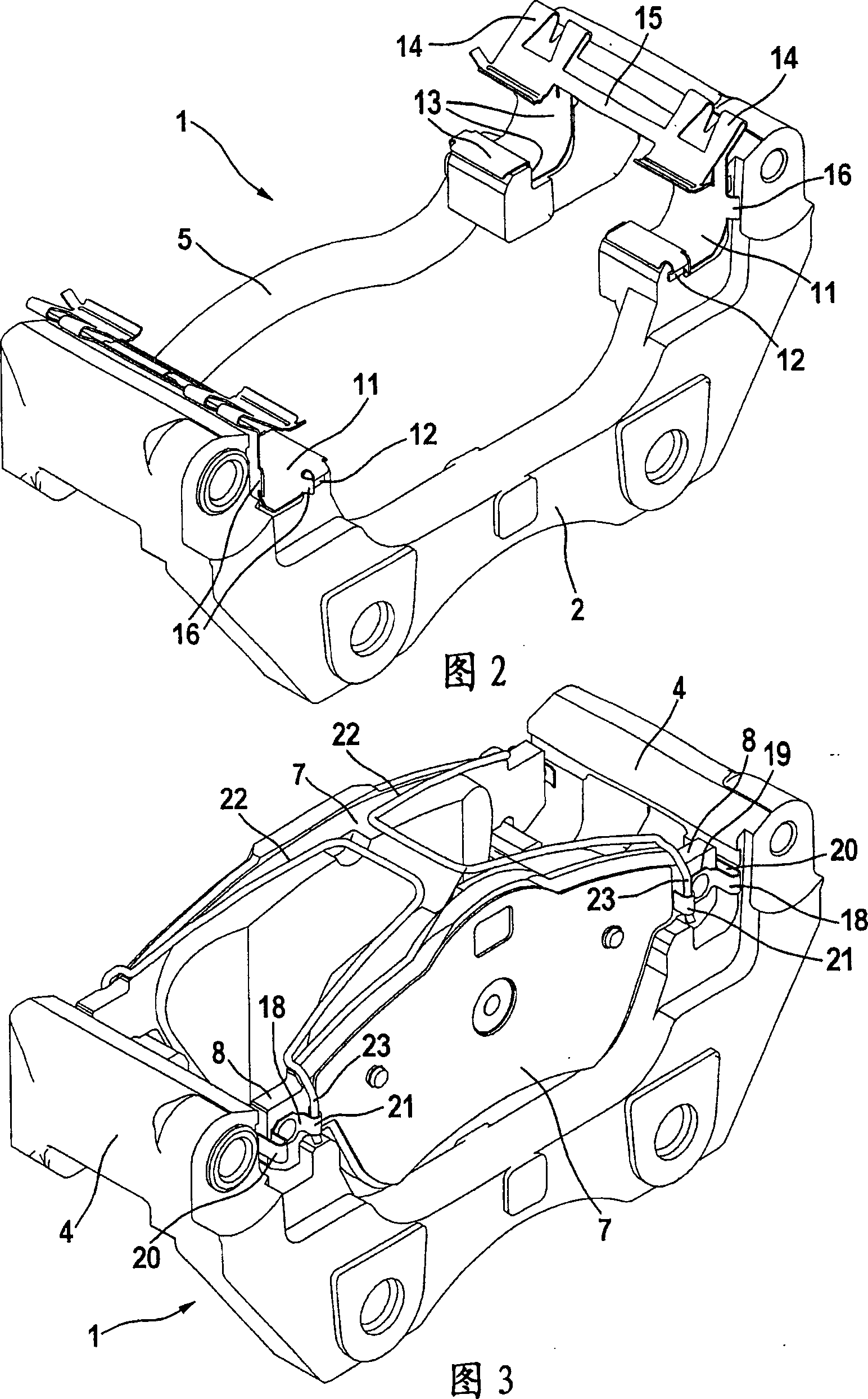

[0015] The brake carrier 1 shown in the figure is a component of a floating-caliper disc brake, as is usually used in motor vehicle braking systems. The brake carrier 1 cooperates here with an associated, but not shown, floating caliper, which is supported axially displaceably on the brake carrier 1 . The brake carrier 1 comprises a base section 2 with fastening holes 3 , via which holes the brake carrier can be mounted in a position-stationary manner or fixedly relative to the vehicle. Attached to the base section 2 is an axially extending support arm 4 which protrudes axially beyond the associated brake disk. To increase the rigidity of the brake carrier, the end of the carrier arm 4 opposite the base section 2 is connected to the web 5 . Formed on the carrier arm 4 is a guide section 6 for receiving a brake shoe 7 which is itself arranged displaceably on the brake carrier 1 . In the guide section 6, each brake shoe 7 is axially movably guided and tangentially supported by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com