Vortex fluid machinery

A technology of fluid machinery and scroll, applied in mechanical equipment, liquid fuel engines, rotary piston machinery, etc., can solve the problems of no water-jet scroll compressors on the market, reduce leakage, reduce noise, and reduce maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

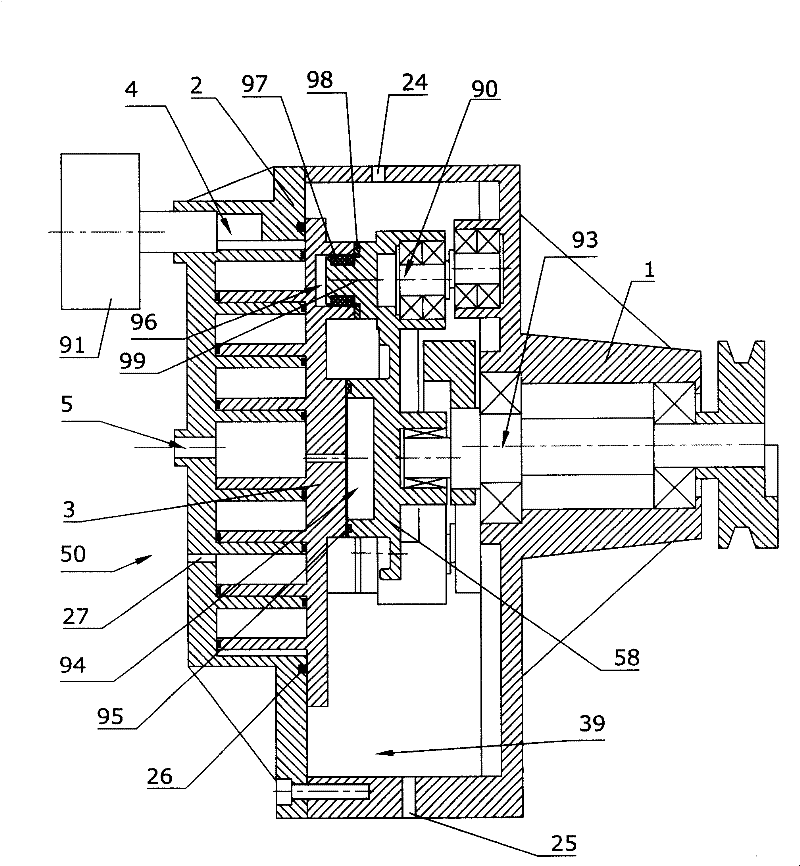

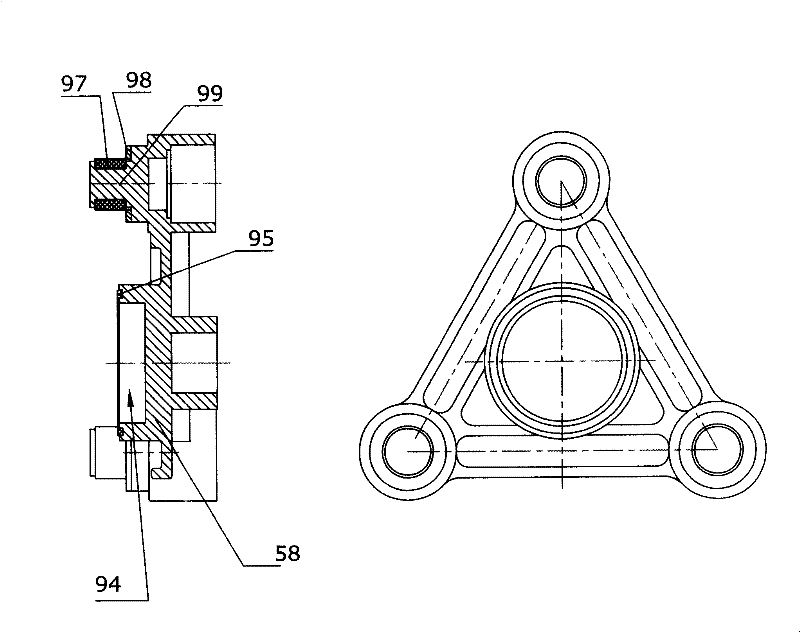

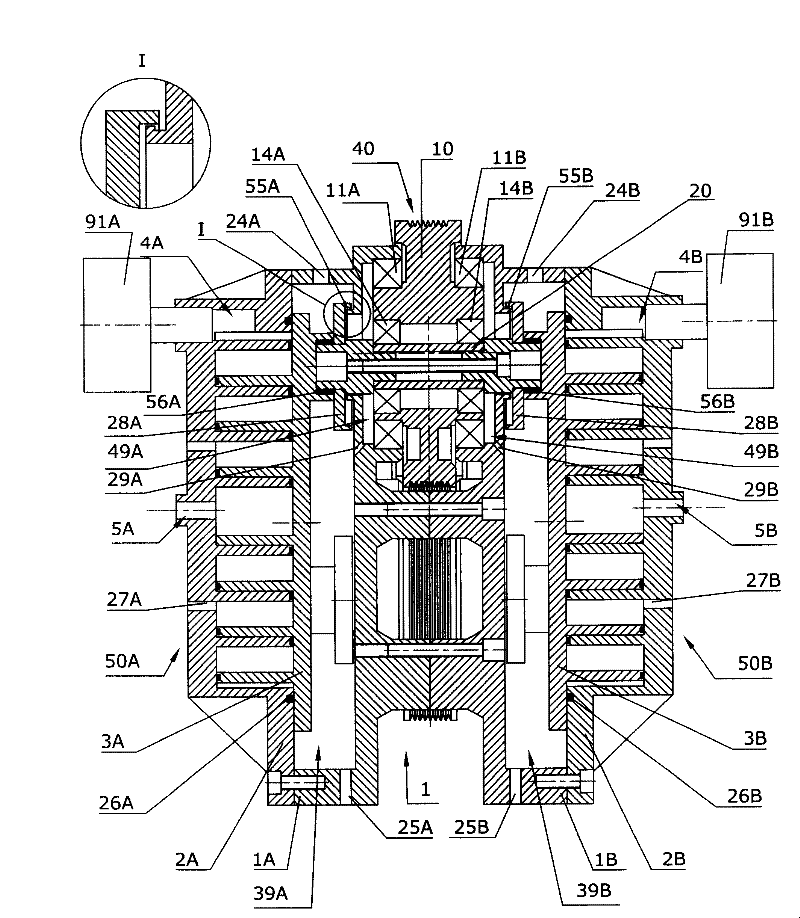

[0025] figure 1 It is a sectional view of an oil-free scroll air compressor according to the first embodiment of the present invention. figure 2 Component diagram for driving the linkage frame for the orbital motion of the compressor. Such as figure 1 As shown, the volume changing device 50 of the compressor includes an orbiting scroll 3 and a fixed scroll 2 . The fixed scroll 2 is connected with the machine base 1 . The drive spindle 93 is rotatably supported on the machine base 1 . The three crankshafts 90, the drive main shaft 93 and the orbital motion drive link frame 58 form a multi-parallelogram mechanism with an anti-rotation function. The three protruding shafts 99 on the orbiting drive link frame 58 are connected with the orbiting scroll 3 via elastic elements 97 to form a closed cavity 96 . The orbiting drive link frame 58 axially supports the orbiting scroll 3 via three thrust washers 98 . Between the orbiting driving link frame 58 and the orbiting scroll 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com