Target material and its use in a sputter process

A target material and absorbing layer technology, applied in the field of target materials, can solve problems such as coating peeling and bubble formation, and achieve the effects of long service life, increased sputtering rate, and high scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

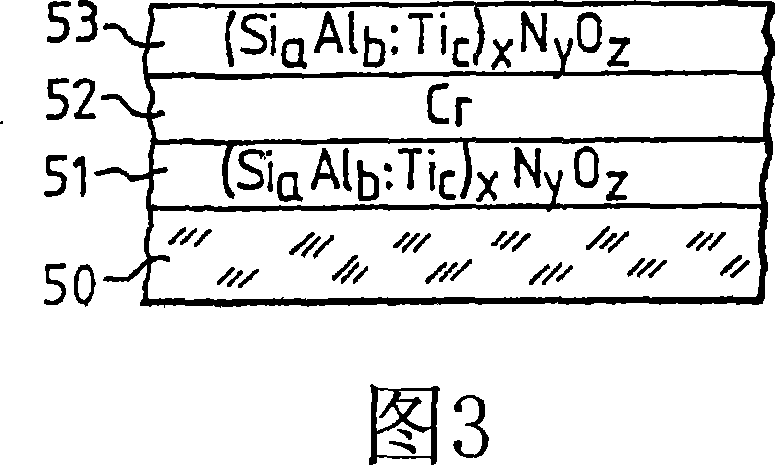

Image

Examples

Embodiment Construction

[0024] FIG. 1 shows a cross-section of a sputtering chamber 1 in which the coating of a substrate takes place. This sputtering chamber 1 comprises a special coating chamber 2 and two buffer chambers 3 , 4 . Adjacent to this sputtering chamber 1 there may be further sputtering chambers to the right and / or left thereof, not shown here. The substrate 5 is conveyed from left to right by the conveying rollers 6 supported by the bracket 7 . Above each of the buffer chambers 3 , 4 a pumping chamber 8 , 9 is arranged, and above each pumping chamber 8 , 9 a pump 10 , 11 is arranged.

[0025] Mounted between the pumps 10 , 11 is a mounting cover 12 , to whose bottom a cathode support 13 is fastened, which supports a cathode 14 with a target 15 . The target 15 consists of silicon, aluminum and titanium or a combination of silicon and titanium only. The anode 16 below the target 15 is fixed on a support 17 which includes a cooling system 18 and is connected to the wall 20 of the coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com