Control method for tracking maximum power point of wind electric power generation

A technology of maximum power point and maximum power, which is applied in control system, generator control, adaptive control, etc., can solve problems such as inaccurate power control, system oscillation, and generators not fully reflecting wind energy, etc., to achieve faster follow-up performance , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

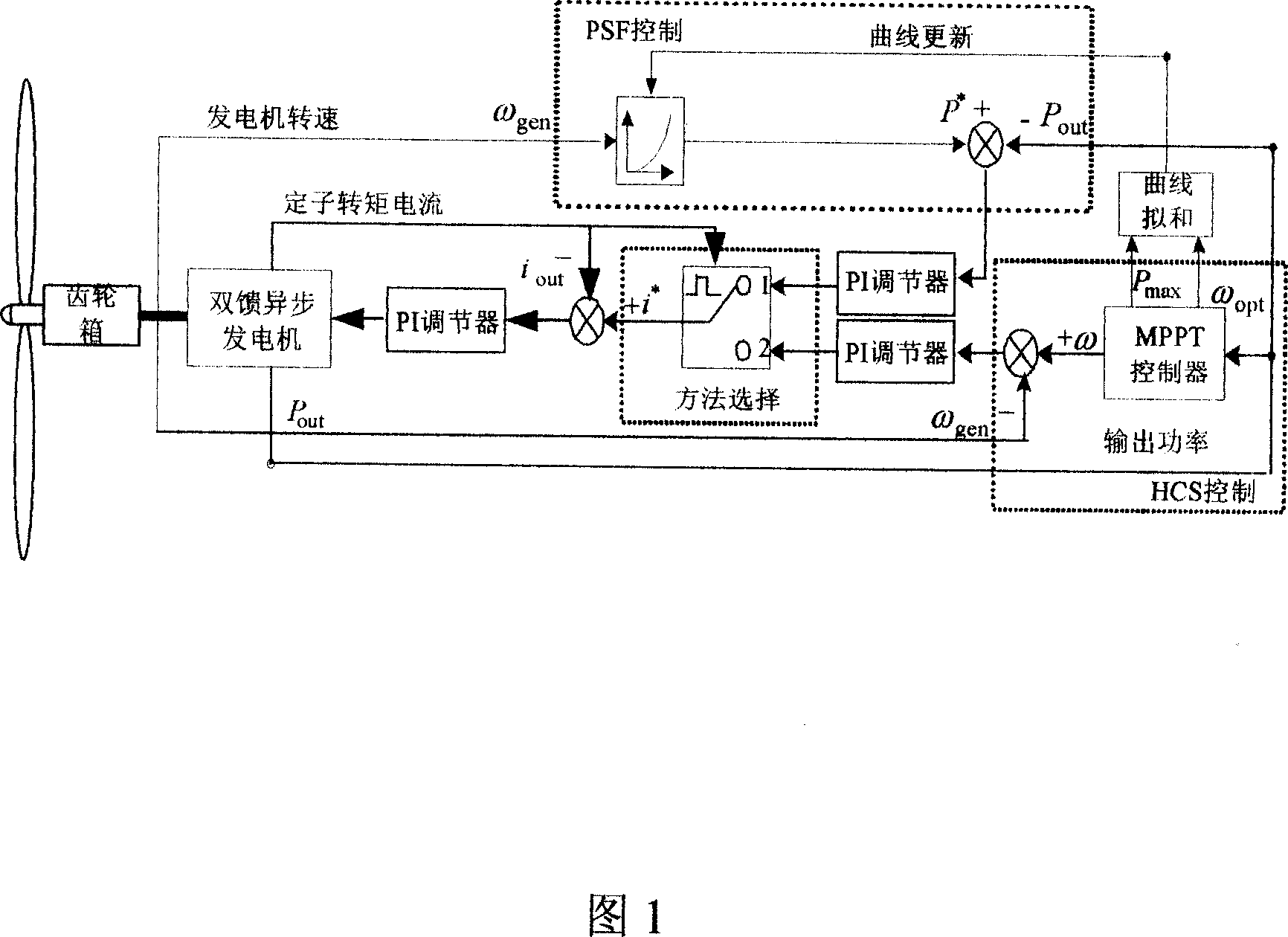

[0018] In this embodiment, a double-closed-loop control method for speed and power is set independently of each other, and the control process is divided into three stages:

[0019] a. In the initial state, the original maximum power curve is obtained according to the original power characteristics of the fan, and power signal feedback control is performed on the fan according to the original maximum power curve during the first operation;

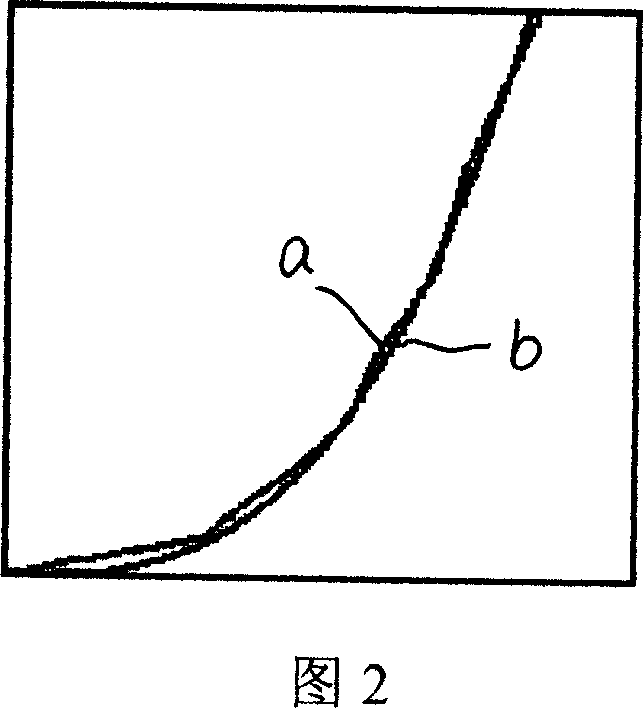

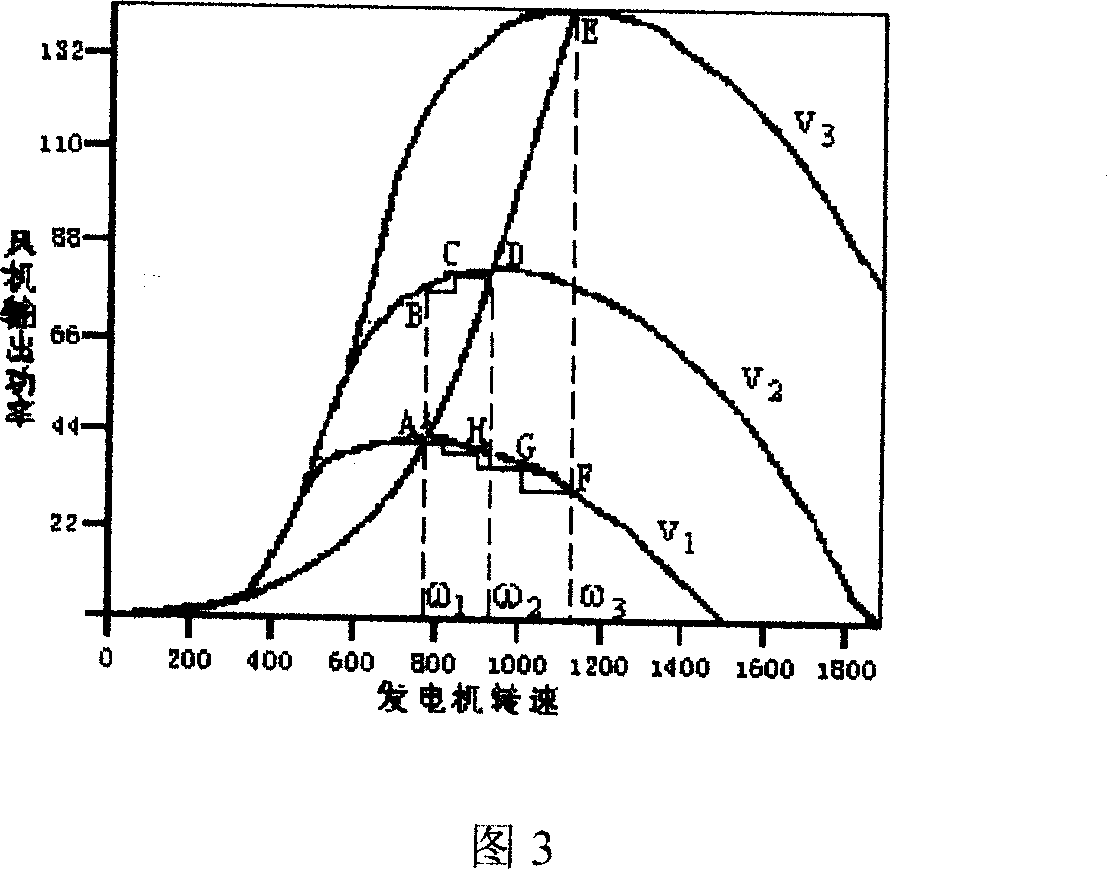

[0020] b. When the change in wind speed is small, use the hill-climbing power optimization control method to obtain the maximum output power at the current wind speed and the corresponding generator speed through the speed disturbance. According to the original maximum power curve and the newly added data points, the maximum power curve Correction is performed, and the curve is corrected in real time every time a new data point is obtained during the operation, so as to obtain the corrected maximum power curve;

[0021] c. When the wind sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com