Diffuser for fluid control valve and fluid control valve

A technology for fluid control valves and diffusers, which is applied in the direction of valve energy absorption devices, valve details, multi-way valves, etc., can solve the problems of small suppression or prevention effects, and achieve the suppression of cavitation and the recovery coefficient of liquid pressure Large, to avoid the effect of large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail based on the embodiments shown in the drawings.

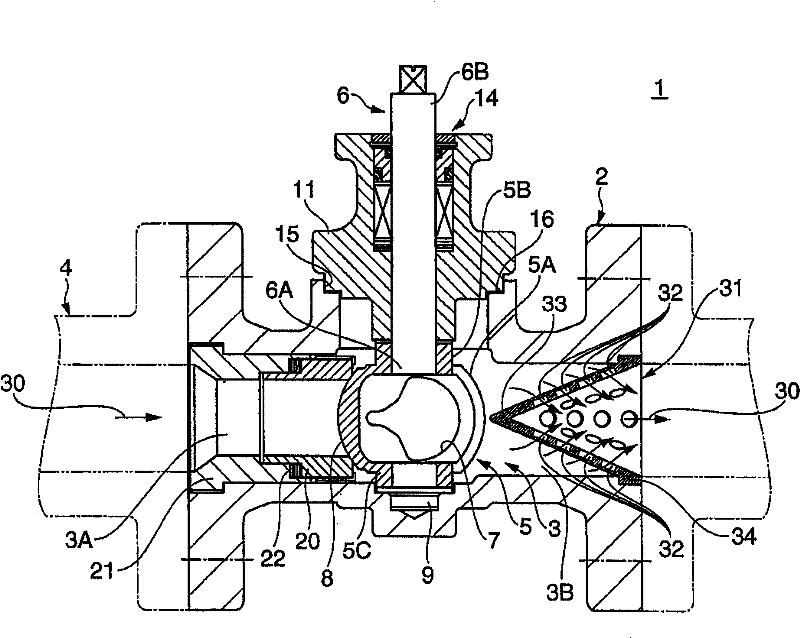

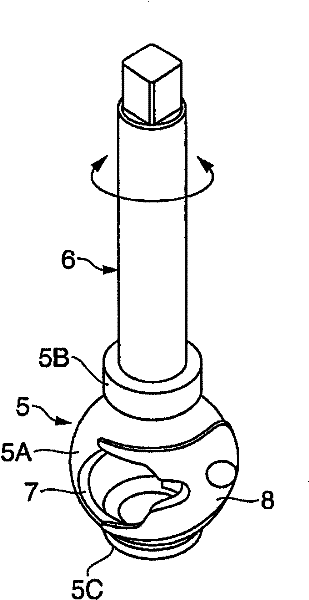

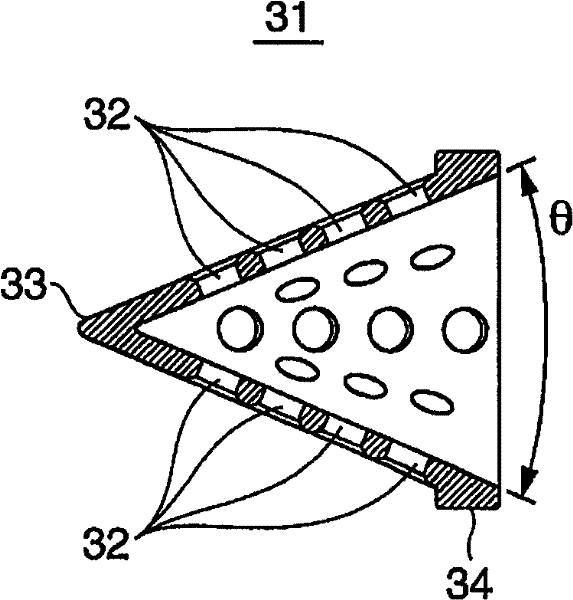

[0025] figure 1 is a cross-sectional view showing an embodiment in which the present invention is applied to a rotary valve, figure 2 is a perspective view of the spool, image 3 is the cross-sectional view of the diffuser, Figure 4 (a) to (c) are diagrams for explaining the operation of the rotary valve, (a) is a diagram showing a fully open state of a ball valve, (b) is a diagram showing an intermediate opening state, and (c) is a diagram showing a fully closed state state diagram. In these drawings, a rotary valve generally indicated by reference numeral 1 includes: a valve main body 2 having a flow path 3 constituted by a through-hole, and connected to the middle of a pipe 4; a freely rotatable valve plug 5, which is It is arranged in the center of the valve main body 2, and controls the opening and closing of the above-mentioned flow passage 3; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com