Polymers produced by using sulphur compounds in the form of transfer agents for controlled radical polymerisation of acrylic acid and the use thereof

A technology of acrylic acid homopolymer and acrylic acid, applied in organic chemistry, chemical instruments and methods, chemical/physical processes, etc., capable of solving complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] The purpose of this example was to synthesize compounds useful in the preparation of the homopolymers and copolymers of the present invention.

[0114] Test n°1

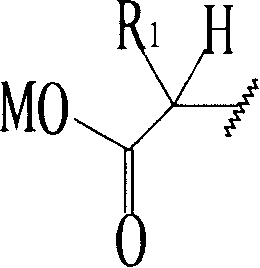

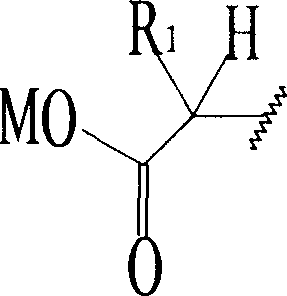

[0115] Preparation of Compound A with the following general formula:

[0116]

[0117] - where R 1 represents an alkyl group having 4 carbon atoms;

[0118] -M 1 and M 2 Represents the sodium atom Na.

[0119] In a beaker stirred with a magnetic stirrer, weigh the following:

[0120] - 30 grams of water;

[0121] - 19.5 g of 2-bromohexanoic acid.

[0122] The mixture was neutralized with 50% sodium hydroxide solution until the pH was equal to 6.5. The temperature was raised to 52°C. A homogeneous solution was then obtained, which was cooled to 43°C.

[0123] Then, 30.8 g of a 25% aqueous solution of disodium trithiocarbonate were added dropwise over 20 minutes.

[0124] Under stirring, it was allowed to react for 2 hours. The S-alkylation reaction was slightly exothermic and the temperature rose...

Embodiment 2

[0127] The purpose of this example is to illustrate how the inventive acrylic acid homopolymers can be obtained in water by using sulfur-containing compounds in a controlled free-radical polymerization process of the RAFT type.

[0128] Test n°2

[0129] In a 1-liter reactor equipped with a mechanical stirrer and a heating device of the oil bath type, the following substances are introduced:

[0130] - 150 grams of water;

[0131] - 50 grams of acrylic acid;

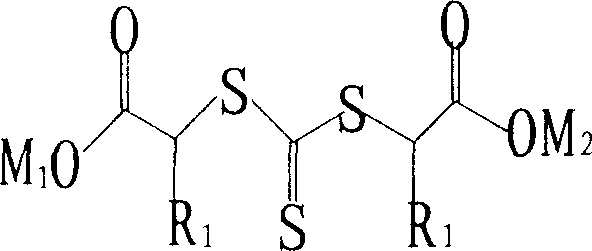

[0132] - 17.1 g of a solution comprising 17.1% of a compound of formula (I'):

[0133]

[0134] - where R 1 represents an alkyl group having 1 carbon atom;

[0135] -M 1 and M 2 Represents the sodium atom Na.

[0136] - 0.4 g of a polymerization initiator of the 4,4'-azobis(4-cyanovaleric acid) type sold under the trade name V501 by the company Aldrich.

[0137] While stirring, the mixture was heated to a temperature of 100°C. The temperature was then maintained at 95°C for 2 hours. This gave a clear, slight...

Embodiment 3

[0195] This example illustrates the use of the polymers of the present invention as grinding aids for minerals, especially calcium carbonate. This example also illustrates the preparation of an aqueous suspension of calcium carbonate according to the invention.

[0196] It is to be noted that these calcium carbonate suspensions according to the invention are finely divided, highly concentrated with minerals and are easy to handle by the end user, ie as paper coating and paper bulk filler.

[0197] For this purpose, an aqueous suspension was prepared from calcium carbonate with a median particle size of about 7 microns from Orgon deposit (France).

[0198] The dry matter concentration of the aqueous suspension was 76% by weight relative to the total mass.

[0199] Grinding aids are added to the suspension according to the amount shown in the table below, and the amount is expressed as a percentage of dry weight relative to the mass of dry calcium carbonate to be ground.

[02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com