Flat resolution correcting method for image optical system and apparatus thereof

A technology of planar resolution and optical system, which is applied in the parts of TV system, image communication, TV, etc., can solve the problems of affecting the accuracy and speed of correction, increasing the complexity of optical system mechanism, and short size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

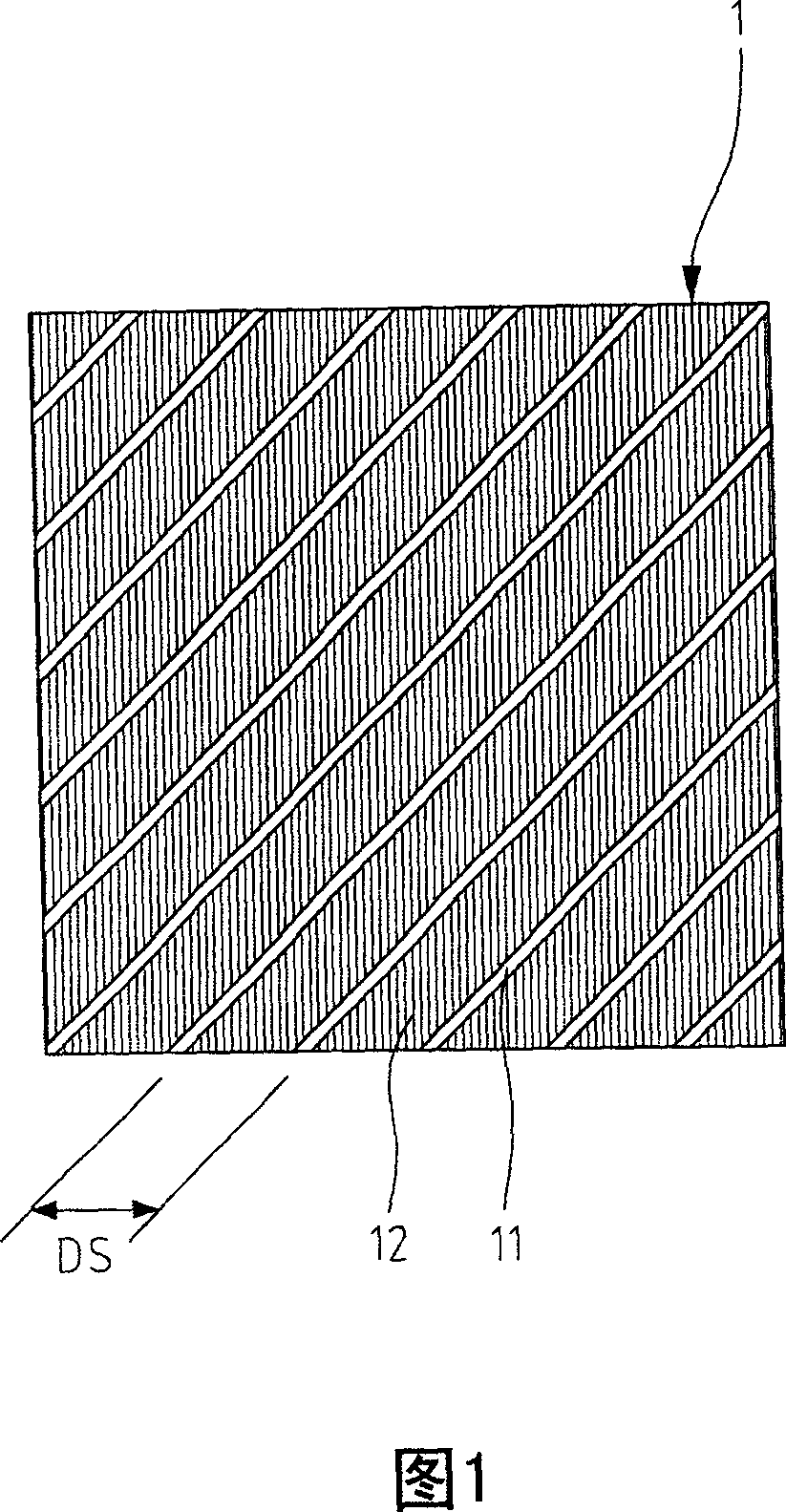

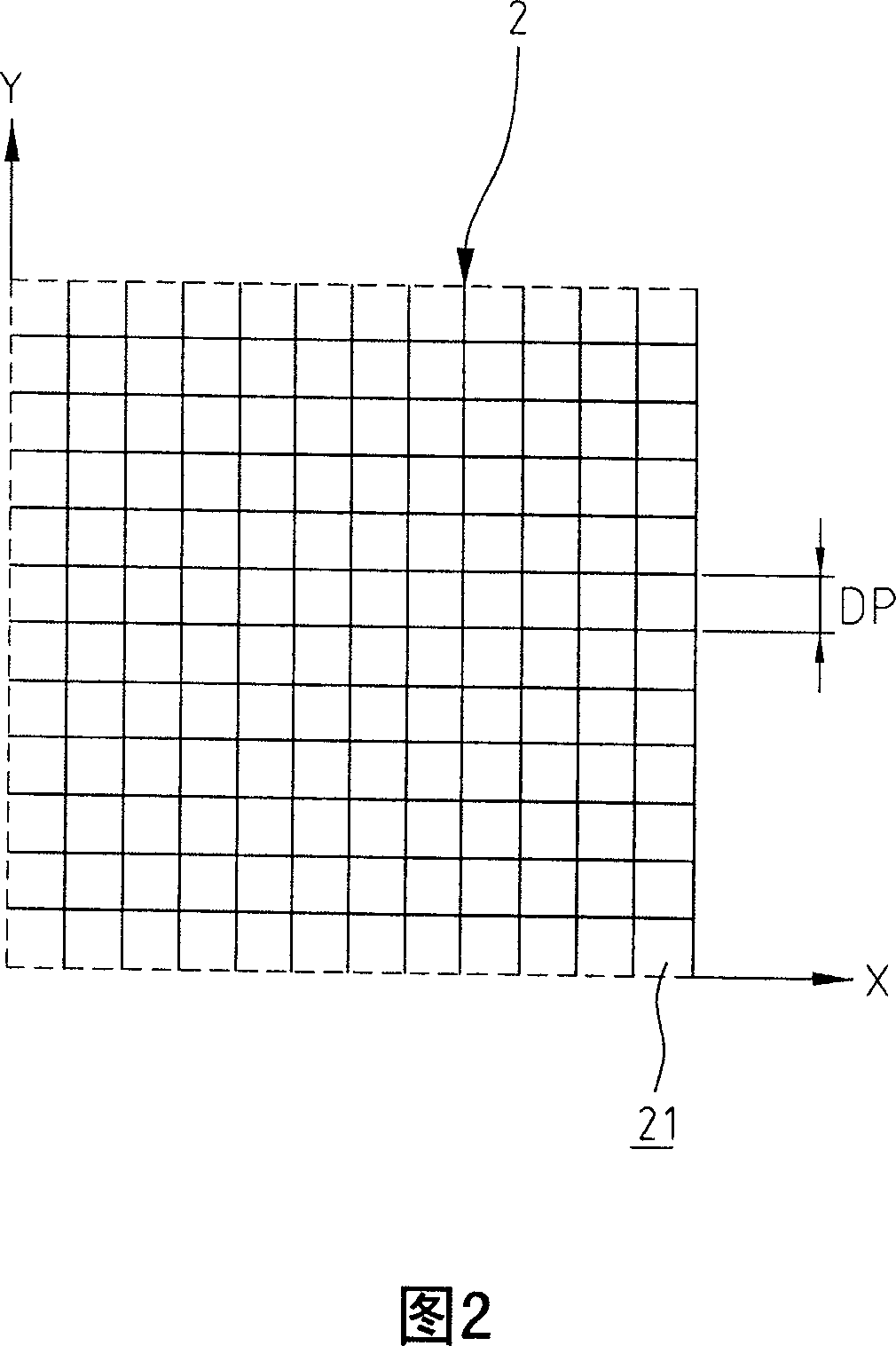

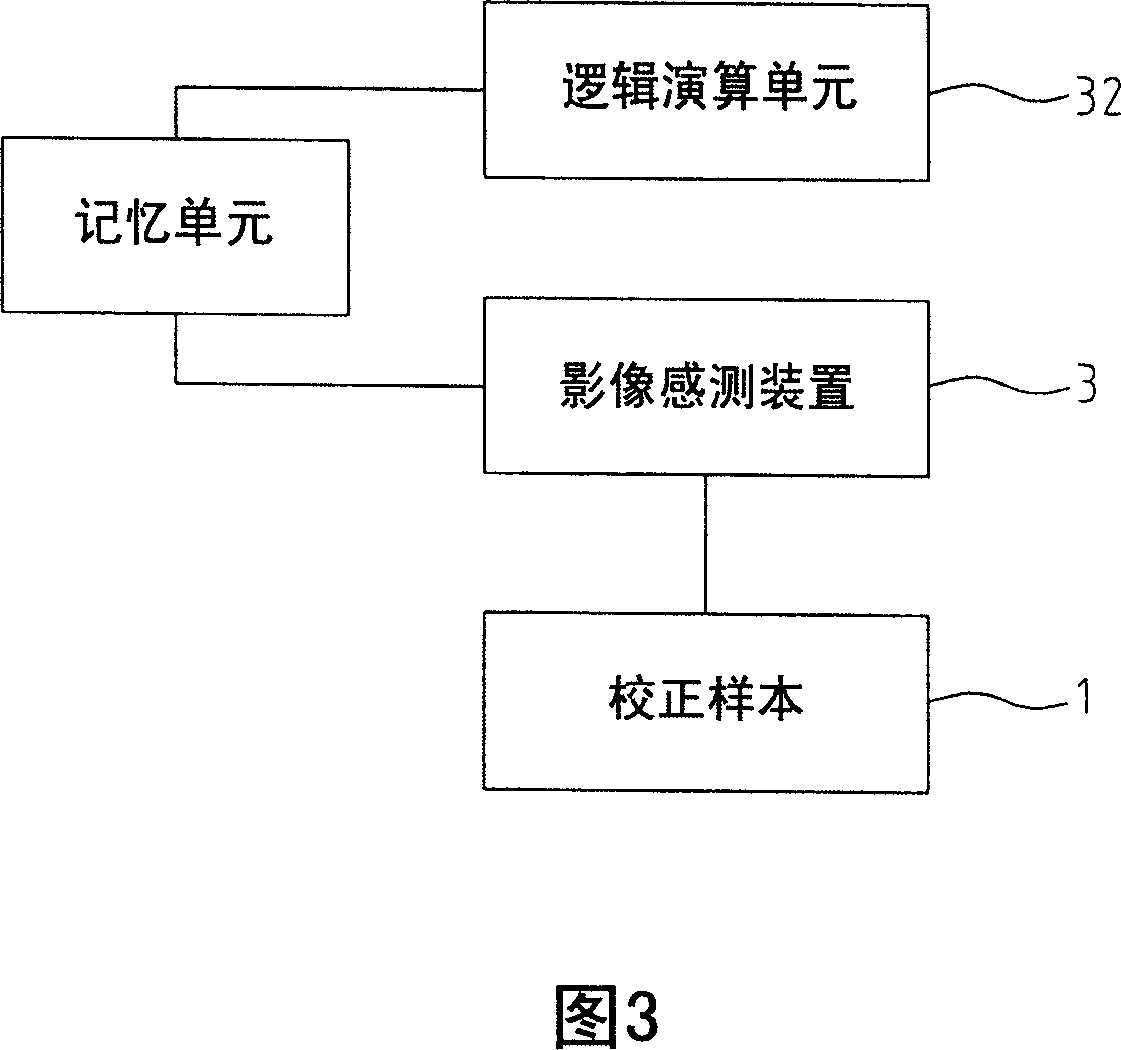

[0030] Fig. 1 is a schematic diagram showing the calibration samples used in the method for correcting the planar resolution of the image optical system of the present invention; Fig. 2 is a schematic diagram showing the coordinates of the sensing components of the method for correcting the planar resolution of the image optical system of the present invention. Shown with reference to Fig. 1, it is the calibration sample 1 used in the present invention, and this calibration sample 1 has several bright lines 11 and dark line 12 alternate stripes, and these bright lines 11 are parallel to each other and have the same width, and these dark lines 12 also The lines are parallel to each other and have the same width, wherein the actual distance between the bright lines 11 is denoted as DS. In addition, as shown in FIG. 2 , it is a schematic diagram of the measurement coordinates 2 not shown in the figure of the image sensing device used in the present invention, wherein each unit cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com